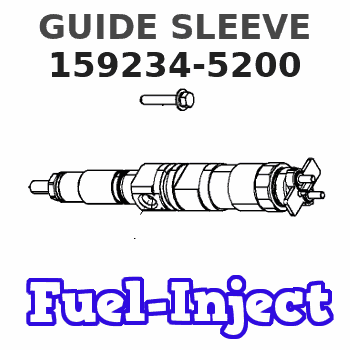

Information guide sleeve

BOSCH

9 421 610 127

9421610127

ZEXEL

159234-5200

1592345200

ISUZU

5157290400

5157290400

Rating:

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

159234-5200

9 421 610 127

5157290400 ISUZU

GUIDE SLEEVE

C 14GJ GUIDE SCREW GOV

C 14GJ GUIDE SCREW GOV

159234-5200

9 421 610 127

223961050A HINO

GUIDE SLEEVE

C 14GJ GUIDE SCREW GOV

C 14GJ GUIDE SCREW GOV

159234-5200

9 421 610 127

223611060A HINO

GUIDE SLEEVE

A C 14GJ GUIDE SCREW GOV

A C 14GJ GUIDE SCREW GOV

159234-5200

9 421 610 127

ME716054 MITSUBISHI

GUIDE SLEEVE

C 14GJ GUIDE SCREW GOV

C 14GJ GUIDE SCREW GOV

159234-5200

9 421 610 127

19334Z9005 NISSAN

GUIDE SLEEVE

C 14GJ GUIDE SCREW GOV

C 14GJ GUIDE SCREW GOV

159234-5200

9 421 610 127

19334Z9005 NISSAN-DIESEL

GUIDE SLEEVE

C 14GJ GUIDE SCREW GOV

C 14GJ GUIDE SCREW GOV

159234-5200

9 421 610 127

SL0124351 MAZDA

GUIDE SLEEVE

C 14GJ GUIDE SCREW GOV

C 14GJ GUIDE SCREW GOV

Information:

Introduction

This Special Instruction contains the necessary procedure in order to install unit injectors for 3114, 3116, and 3126 MUI engines.Removal and Installation Procedure

Note: To avoid damage to the unit injector during removal of the unit injector from the cylinder head, refer to the Service Manual for the removal procedure of the unit injector.Use the latest process for servicing the unit injector sleeves in the cylinder head before you install replacement unit injectors. Refer to the Service Manual and other service news articles in order to find the latest service information, including new tools and procedures.Before a new unit injector or a remanufactured unit injector is installed into an engine, take adequate precautions in order to clean the internal fuel lines and the unit injector sleeve. Also, install a new Caterpillar high efficiency fuel filter.Lubricate the injector rack bar with clean diesel fuel or 1U-8265 Penetrating Oil .

Illustration 1 g02144296

Incorrect testing procedure for the tappet springDo not depress the tappet spring. Refer to Illustration 1. Do not force the injector rack bar in and out since this action may damage the internal parts of the unit injector. A tight rack on a unit injector that is not installed in the engine is not an indication of a faulty unit injector. Forcing the injector rack bar in and out may cause the unit injector to become damaged. Forcing the injector rack bar in and out may possibly void all the warranty.Do not test the unit injectors prior to engine installation. The unit injectors are tested 100% at the factory and Pop Testing may contaminate the unit injector.Before you install the unit injector, apply clean engine oil on the O-ring seals for ease of installation.Install the unit injector according to the procedure in the Service Manual by using 173-1530 Injector Seating Tool . Tighten the unit injector clamp retaining bolt to a torque of 12 3 N m (9 2 lb ft).Verify the following parameters and settings according to the procedures in the Service Manual: unit injector synchronization, fuel setting, fuel timing and valve lash. Adjust the parameters and settings in order to meet specifications only.

This Special Instruction contains the necessary procedure in order to install unit injectors for 3114, 3116, and 3126 MUI engines.Removal and Installation Procedure

Note: To avoid damage to the unit injector during removal of the unit injector from the cylinder head, refer to the Service Manual for the removal procedure of the unit injector.Use the latest process for servicing the unit injector sleeves in the cylinder head before you install replacement unit injectors. Refer to the Service Manual and other service news articles in order to find the latest service information, including new tools and procedures.Before a new unit injector or a remanufactured unit injector is installed into an engine, take adequate precautions in order to clean the internal fuel lines and the unit injector sleeve. Also, install a new Caterpillar high efficiency fuel filter.Lubricate the injector rack bar with clean diesel fuel or 1U-8265 Penetrating Oil .

Illustration 1 g02144296

Incorrect testing procedure for the tappet springDo not depress the tappet spring. Refer to Illustration 1. Do not force the injector rack bar in and out since this action may damage the internal parts of the unit injector. A tight rack on a unit injector that is not installed in the engine is not an indication of a faulty unit injector. Forcing the injector rack bar in and out may cause the unit injector to become damaged. Forcing the injector rack bar in and out may possibly void all the warranty.Do not test the unit injectors prior to engine installation. The unit injectors are tested 100% at the factory and Pop Testing may contaminate the unit injector.Before you install the unit injector, apply clean engine oil on the O-ring seals for ease of installation.Install the unit injector according to the procedure in the Service Manual by using 173-1530 Injector Seating Tool . Tighten the unit injector clamp retaining bolt to a torque of 12 3 N m (9 2 lb ft).Verify the following parameters and settings according to the procedures in the Service Manual: unit injector synchronization, fuel setting, fuel timing and valve lash. Adjust the parameters and settings in order to meet specifications only.

Have questions with 159234-5200?

Group cross 159234-5200 ZEXEL

Isuzu

159234-5200

9 421 610 127

5157290400

GUIDE SLEEVE

Hino

159234-5200

9 421 610 127

223961050A

GUIDE SLEEVE

159234-5200

9 421 610 127

223611060A

GUIDE SLEEVE

Mitsubishi

159234-5200

9 421 610 127

ME716054

GUIDE SLEEVE

Nissan

159234-5200

9 421 610 127

19334Z9005

GUIDE SLEEVE

Nissan-Diesel

159234-5200

9 421 610 127

19334Z9005

GUIDE SLEEVE

Mazda

159234-5200

9 421 610 127

SL0124351

GUIDE SLEEVE