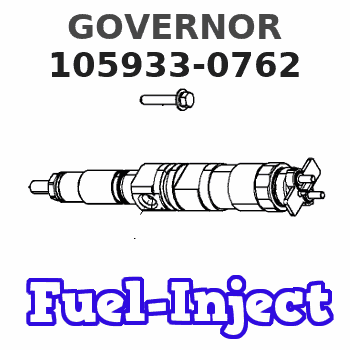

Information governor

BOSCH

9 420 613 786

9420613786

ZEXEL

105933-0762

1059330762

Rating:

Scheme ###:

| 1. | [1] | 159360-0620 | GOVERNOR HOUSING |

| 4. | [1] | 159362-5120 | PLATE |

| 5. | [10] | 139006-6100 | BLEEDER SCREW |

| 5. | [10] | 139006-6100 | BLEEDER SCREW |

| 7. | [1] | 139709-0100 | O-RING |

| 8. | [1] | 159364-4820 | LEVER SHAFT |

| 9. | [1] | 159362-6620 | CONTROL LEVER |

| 10. | [1] | 016010-0740 | LOCKING WASHER |

| 11/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 11/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 11/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 11/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 11/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 11/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 11/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 11/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 11/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 12. | [1] | 159368-7900 | COILED SPRING |

| 13. | [1] | 159362-2500 | CONTROL LEVER |

| 15. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 16. | [1] | 159364-5000 | CAPSULE |

| 17. | [1] | 159362-2620 | CONTROL LEVER |

| 18. | [1] | 159215-0300 | COILED SPRING |

| 20. | [1] | 159364-9800 | LEVER SHAFT |

| 21. | [2] | 020104-1240 | BLEEDER SCREW |

| 22. | [1] | 159362-0600 | CONTROL LEVER |

| 23. | [2] | 139608-0600 | PACKING RING |

| 23. | [2] | 139608-0600 | PACKING RING |

| 24. | [1] | 159362-0700 | PLAIN WASHER |

| 24B/1. | [0] | 139408-1000 | SHIM D16&8T0.5 |

| 24B/1. | [0] | 139408-1300 | SHIM D16&8T0.2 |

| 24C. | [1] | 159362-0700 | PLAIN WASHER |

| 24D. | [1] | 139308-2100 | PLAIN WASHER |

| 25. | [1] | 159238-4200 | LOCKING WASHER |

| 25B. | [1] | 159238-4200 | LOCKING WASHER |

| 26. | [1] | 159390-6600 | CONTROL LEVER |

| 27. | [1] | 159369-2000 | COILED SPRING |

| 28. | [1] | 159364-6000 | BUSHING |

| 29. | [1] | 014110-8440 | LOCKING WASHER |

| 30. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 31. | [1] | 155615-1100 | FLAT-HEAD SCREW M6P1.0L37 |

| 31B. | [1] | 153505-0800 | FLAT-HEAD SCREW |

| 32. | [2] | 013030-6040 | UNION NUT M6P1H3.6 |

| 32. | [2] | 013030-6040 | UNION NUT M6P1H3.6 |

| 35. | [1] | 159361-1020 | GOVERNOR COVER |

| 43. | [1] | 159364-0700 | LEVER SHAFT |

| 44. | [1] | 159364-0800 | BEARING PIN |

| 45. | [2] | 016010-0640 | LOCKING WASHER |

| 46. | [1] | 159362-8620 | TENSIONING LEVER |

| 46/1. | [1] | 159362-8521 | TENSIONING LEVER |

| 46/2. | [1] | 159362-8721 | GUIDE LEVER |

| 46/3. | [1] | 159364-4201 | BEARING PIN |

| 46/4. | [1] | 159368-7700 | COILED SPRING |

| 46/5. | [1] | 016010-0540 | LOCKING WASHER |

| 46/6. | [1] | 016010-0440 | LOCKING WASHER |

| 46/7. | [1] | 159364-4121 | RACK |

| 46/8. | [1] | 159364-4300 | UNION NUT |

| 46/9. | [1] | 159364-4400 | FLAT-HEAD SCREW |

| 46/10. | [1] | 159368-6900 | COILED SPRING |

| 46/11. | [1] | 159368-7000 | COILED SPRING |

| 46/13. | [1] | 016010-0540 | LOCKING WASHER |

| 46/14. | [1] | 159364-1900 | FLAT-HEAD SCREW |

| 46/15. | [1] | 159364-1800 | UNION NUT |

| 46/16. | [1] | 159368-9500 | COILED SPRING |

| 47. | [2] | 016110-1020 | LOCKING WASHER |

| 48. | [2] | 159237-0200 | CAPSULE |

| 51. | [9] | 020106-3840 | BLEEDER SCREW |

| 56. | [1] | 159362-3720 | LEVER GROUP |

| 57. | [2] | 020105-1040 | BLEEDER SCREW M5P0.8L10 |

| 58. | [1] | 146711-0000 | PLATE |

| 59. | [1] | 154413-3600 | BUSHING |

| 60. | [1] | 146716-0000 | UNION NUT |

| 65. | [1] | 154612-3320 | RACK SENSOR ASSY |

| 65/1. | [1] | 479775-5720 | RACK SENSOR |

| 65/2. | [1] | 154614-8700 | JOINT CONNECTION |

| 65/3. | [1] | 026524-3040 | GASKET |

| 65/4. | [1] | 029310-6280 | SHIM D11.5&6.4T1.50 |

| 65/5. | [1] | 154614-1900 | UNION NUT |

| 70. | [1] | 154416-4500 | COILED SPRING |

| 71. | [2] | 154413-2600 | GASKET |

| 72. | [1] | 154415-1020 | DIAPHRAGM |

| 75. | [1] | 154415-1100 | SLOTTED WASHER |

| 76. | [1] | 014110-6440 | LOCKING WASHER |

| 77. | [1] | 013030-6010 | UNION NUT |

| 79. | [1] | 154413-4000 | FLAT-HEAD SCREW |

| 80. | [1] | 154404-5600 | COVER |

| 82. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 83. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 84. | [1] | 154035-1600 | CAP NUT |

| 88. | [1] | 029731-0180 | EYE BOLT |

| 89. | [2] | 026510-1340 | GASKET D13.4&10.2T1 |

| 91. | [3] | 154062-2900 | BLEEDER SCREW |

| 92A. | [3] | 014110-6440 | LOCKING WASHER |

| 95. | [1] | 029111-2090 | CAPSULE |

| 96. | [1] | 029331-2130 | GASKET |

| 97. | [1] | 159364-2000 | CAPSULE |

| 100. | [1] | 154101-1020 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 110. | [1] | 154123-2320 | SLIDING PIECE |

| 111/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 111/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 111/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 111/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 111/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 111/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 111/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 111/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 111/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 112. | [1] | 159364-2100 | TERMINAL STUD |

| 130. | [1] | 159367-1600 | GOVERNOR SPRING |

| 131. | [1] | 159367-6600 | GOVERNOR SPRING |

| 132. | [1] | 159368-6500 | COILED SPRING |

| 133. | [1] | 159368-3820 | SPRING PACK |

| 133/1. | [1] | 159364-2200 | GUIDE SLEEVE |

| 133/2. | [1] | 159368-1300 | COILED SPRING |

| 133/3. | [1] | 159368-0400 | COILED SPRING |

| 133/4/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 133/4/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 133/4/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 133/4/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 133/4/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 133/4/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 133/4/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 133/4/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 133/4/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 135. | [1] | 159364-2300 | FLAT-HEAD SCREW |

| 137. | [1] | 159364-2000 | CAPSULE |

| 140. | [1] | 159364-2500 | LEVER SHAFT |

| 145. | [1] | 159233-5700 | UNION NUT |

| 149. | [1] | 159237-5400 | CAPSULE |

| 150. | [1] | 159364-2600 | SLOTTED WASHER |

| 151. | [1] | 159364-2700 | SLOTTED WASHER |

| 155. | [1] | 159363-3221 | STRAP |

| 156. | [1] | 010235-1020 | HEX-SOCKET-HEAD CAP SCREW |

| 160. | [1] | 159362-3420 | LEVER GROUP |

| 160/1. | [1] | 159364-4920 | LEVER SHAFT |

| 160/2. | [1] | 159362-1020 | CONTROL LEVER |

| 160/3. | [1] | 159362-2000 | CONTROL LEVER |

| 160/4. | [2] | 159362-1300 | SHIM |

| 160/4. | [2] | 159362-1300 | SHIM |

| 160/5. | [2] | 016010-0840 | LOCKING WASHER |

| 160/5. | [2] | 016010-0840 | LOCKING WASHER |

| 160/6. | [1] | 159368-7400 | COILED SPRING |

| 162. | [1] | 139411-0600 | SHIM |

| 163. | [1] | 159238-3000 | LOCKING WASHER |

| 164. | [1] | 139610-0800 | PACKING RING |

| 168. | [1] | 159380-0300 | CONTROL LEVER |

| 169. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 170. | [1] | 159382-6420 | CONTROL LEVER |

| 172. | [4] | 020106-1240 | BLEEDER SCREW M6P1.0L12 |

| 172. | [4] | 020106-1240 | BLEEDER SCREW M6P1.0L12 |

| 173. | [1] | 154013-3800 | FLAT-HEAD SCREW |

| 173B. | [1] | 154013-3900 | FLAT-HEAD SCREW |

| 173C. | [1] | 154013-4600 | FLAT-HEAD SCREW |

| 174. | [1] | 154013-3700 | FLAT-HEAD SCREW |

| 174B. | [1] | 154013-4400 | FLAT-HEAD SCREW |

| 174C. | [1] | 154013-4700 | FLAT-HEAD SCREW |

| 175. | [1] | 154013-2100 | FLAT-HEAD SCREW |

| 176. | [1] | 154011-4800 | UNION NUT |

| 177. | [1] | 154011-4700 | UNION NUT |

| 178. | [1] | 013131-0040 | UNION NUT M10P1.25H6 |

| 181. | [1] | 159383-0600 | CONTROL LEVER |

| 236. | [1] | 154390-4200 | GASKET |

| 237. | [1] | 154390-2500 | GASKET |

| 250. | [1] | 159398-7320 | BRACKET |

| 251. | [2] | 154339-4000 | COILED SPRING |

| 257. | [2] | 154156-1600 | TUBE |

| 270. | [1] | 159362-3520 | GUIDE PLATE |

| 271. | [2] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 300. | [1] | 159374-9900 | CAM PLATE |

| 301. | [1] | 016010-0840 | LOCKING WASHER |

| 303. | [1] | 016010-0540 | LOCKING WASHER |

| 311. | [2] | 159237-5400 | CAPSULE |

| 321/1. | [1] | 159274-5100 | STOP PIN L72.5 |

| 321/1. | [1] | 159274-5200 | STOP PIN L73 |

| 321/1. | [1] | 159274-5300 | STOP PIN L73.5 |

| 321/1. | [1] | 159274-5400 | STOP PIN L74 |

| 321/1. | [1] | 159274-5500 | STOP PIN L74.5 |

| 321/1. | [1] | 159274-5600 | STOP PIN L75 |

| 321/1. | [1] | 159274-5700 | STOP PIN L75.5 |

| 321/1. | [1] | 159274-5800 | STOP PIN L76 |

| 321/1. | [1] | 159274-5900 | STOP PIN L76.5 |

| 321/1. | [1] | 159274-6000 | STOP PIN L77 |

| 321/1. | [1] | 159274-6100 | STOP PIN L77.5 |

| 321/1. | [1] | 159274-6200 | STOP PIN L78 |

| 321/1. | [1] | 159274-6300 | STOP PIN L78.5 |

| 321/1. | [1] | 159274-6400 | STOP PIN L79 |

| 321/1. | [1] | 159274-6500 | STOP PIN L79.5 |

| 321/1. | [1] | 159274-6600 | STOP PIN L80 |

| 321/1. | [1] | 159274-6700 | STOP PIN L80.5 |

| 321/1. | [1] | 159274-6800 | STOP PIN L81 |

| 321/1. | [1] | 159274-6900 | STOP PIN L81.5 |

| 321/1. | [1] | 159274-7000 | STOP PIN L82 |

| 321/1. | [1] | 159274-7100 | STOP PIN L82.5 |

| 321/1. | [1] | 159274-7200 | STOP PIN L83 |

| 321/1. | [1] | 159274-7300 | STOP PIN L83.5 |

| 321/1. | [1] | 159274-7400 | STOP PIN L84 |

| 321/1. | [1] | 159274-7500 | STOP PIN L84.5 |

| 321/1. | [1] | 159274-7600 | STOP PIN L85 |

| 321/1. | [1] | 159274-7700 | STOP PIN L85.5 |

| 321/1. | [1] | 159274-7800 | STOP PIN L86 |

| 321/1. | [1] | 159274-7900 | STOP PIN L86.5 |

| 321/1. | [1] | 159274-8000 | STOP PIN L87 |

| 321/1. | [1] | 159274-8100 | STOP PIN L87.5 |

| 321/1. | [1] | 159274-8200 | STOP PIN L88 |

| 321/1. | [1] | 159274-8300 | STOP PIN L88.5 |

| 321/1. | [1] | 159274-8400 | STOP PIN L89 |

| 321/1. | [1] | 159274-8500 | STOP PIN L89.5 |

| 321/1. | [1] | 159274-8600 | STOP PIN L90 |

| 340. | [1] | 159397-0420 | BRACKET |

| 340B. | [1] | 159397-0500 | PLATE |

| 341. | [1] | 020106-1240 | BLEEDER SCREW M6P1.0L12 |

| 341B. | [1] | 020106-1840 | BLEEDER SCREW M6P1L18 |

| 360. | [1] | 159398-8820 | BRACKET |

| 361. | [1] | 010110-2040 | BLEEDER SCREW M10P1.25L20 |

| 362. | [2] | 020106-1440 | BLEEDER SCREW M6P1.0L14 |

| 370. | [1] | 159399-1600 | BRACKET |

| 371. | [1] | 139012-0100 | BLEEDER SCREW |

Include in #1:

107691-3234

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Adjusting the engine speeds

To adjust engine speed, remove the cooling fan and install the safety cover over the fan to prevent getting hurt. For speed adjustment specification, see 8-05.(1) The upper limit of engine speed can be adjusted with the HIGH-SPEED stopper bolt.This stopper bolt has been set properly and sealed in the factory before shipping of the engine. Never tamper with the seal unless it is necessary.(2) The lower limit of engine speed can be adjusted with the LOW-SPEED stopper bolt.(3) Never remove the sealing cap unnecessarily to adjust the torque spring set. For the proper disassembling procedure, see 4-02. CAUTION Warm up the engine (until coolant temperature rises up to 60°C or above) before adjusting engine speeds.(4) During running of the engine for speed adjustment, check the engine for gas leak, water leak, oil leak, and fuel leak.(5) After adjustment, perform engine acceleration and deceleration test to confirm that the engine is free from hunting and smoking.

HIGH-SPEED and LOW-SPEED Set BoltsChecking and adjustment of nozzles

To check and adjust the injection nozzles, use the following procedure:1. Injection start pressure(1) Remove the nozzle assembly to be tested from the cylinder head and set the nozzle on the nozzle tester.Perform air bleeding by moving the tester handle up and down.(2) Operate the handle at a speed of 60 rpm or more and read the gauge pressure of fuel injected from the nozzle.* Injection start pressure: 140 +10-0kgf/cm2 [13.7+1.0-0 MPa(3) If reading of gauge pressure is not within the specified range, disassemble the nozzle and vary thickness of the adjusting shim.Increasing or decreasing shim thickness by 0.1 mm will cause injection pressure to vary about 10 kgf/cm2 [0.98 MPa]

Testing Injection Start Pressure(4) When installing the nozzle, use the following values of tightening torque:* Nozzle tightening (to cylinder head) torque: 5.0 - 6.0 kgf m [49 - 59 N m]* Nozzle retaining nut tightening torque: 3.5 - 4.0 kgf m [34 - 39 N m]* Nozzle union collar tightening torque: 2.5 - 3.0 kgf m [25 - 29 N m]

Installing Nozzle Assembly2. Chattering testOperate the tester handle at a speed of about 1 stroke per second.(1) Needle valve oscillationIt is considered normal if the nozzle injects fuel mist, making intermittent sounds, and oscillations of the needle valve are transmitted to the handle.(2) State of fuel mist injectionThe nozzle should inject fuel mist straight in the direction of its axis. A nozzle is defective if it does not inject steadily or it injects fuel in several separate stripes.A nozzle is defective if it spills fuel accumulated on the bottom of the nozzle after chattering test. However, a very small drop of fuel remaining on the tip of nozzle after chattering test may be regarded as normal.

Charttering Test

After-spilling3. Injection testOperate the tester handle at a speed of 4 to 6 strokes per second.* A nozzle should inject fuel mist uniformly in the shape of a cone.4. Checking the compression pressure(1) Make sure of the following:(a) All of the engine oil level, air cleaner,

To adjust engine speed, remove the cooling fan and install the safety cover over the fan to prevent getting hurt. For speed adjustment specification, see 8-05.(1) The upper limit of engine speed can be adjusted with the HIGH-SPEED stopper bolt.This stopper bolt has been set properly and sealed in the factory before shipping of the engine. Never tamper with the seal unless it is necessary.(2) The lower limit of engine speed can be adjusted with the LOW-SPEED stopper bolt.(3) Never remove the sealing cap unnecessarily to adjust the torque spring set. For the proper disassembling procedure, see 4-02. CAUTION Warm up the engine (until coolant temperature rises up to 60°C or above) before adjusting engine speeds.(4) During running of the engine for speed adjustment, check the engine for gas leak, water leak, oil leak, and fuel leak.(5) After adjustment, perform engine acceleration and deceleration test to confirm that the engine is free from hunting and smoking.

HIGH-SPEED and LOW-SPEED Set BoltsChecking and adjustment of nozzles

To check and adjust the injection nozzles, use the following procedure:1. Injection start pressure(1) Remove the nozzle assembly to be tested from the cylinder head and set the nozzle on the nozzle tester.Perform air bleeding by moving the tester handle up and down.(2) Operate the handle at a speed of 60 rpm or more and read the gauge pressure of fuel injected from the nozzle.* Injection start pressure: 140 +10-0kgf/cm2 [13.7+1.0-0 MPa(3) If reading of gauge pressure is not within the specified range, disassemble the nozzle and vary thickness of the adjusting shim.Increasing or decreasing shim thickness by 0.1 mm will cause injection pressure to vary about 10 kgf/cm2 [0.98 MPa]

Testing Injection Start Pressure(4) When installing the nozzle, use the following values of tightening torque:* Nozzle tightening (to cylinder head) torque: 5.0 - 6.0 kgf m [49 - 59 N m]* Nozzle retaining nut tightening torque: 3.5 - 4.0 kgf m [34 - 39 N m]* Nozzle union collar tightening torque: 2.5 - 3.0 kgf m [25 - 29 N m]

Installing Nozzle Assembly2. Chattering testOperate the tester handle at a speed of about 1 stroke per second.(1) Needle valve oscillationIt is considered normal if the nozzle injects fuel mist, making intermittent sounds, and oscillations of the needle valve are transmitted to the handle.(2) State of fuel mist injectionThe nozzle should inject fuel mist straight in the direction of its axis. A nozzle is defective if it does not inject steadily or it injects fuel in several separate stripes.A nozzle is defective if it spills fuel accumulated on the bottom of the nozzle after chattering test. However, a very small drop of fuel remaining on the tip of nozzle after chattering test may be regarded as normal.

Charttering Test

After-spilling3. Injection testOperate the tester handle at a speed of 4 to 6 strokes per second.* A nozzle should inject fuel mist uniformly in the shape of a cone.4. Checking the compression pressure(1) Make sure of the following:(a) All of the engine oil level, air cleaner,