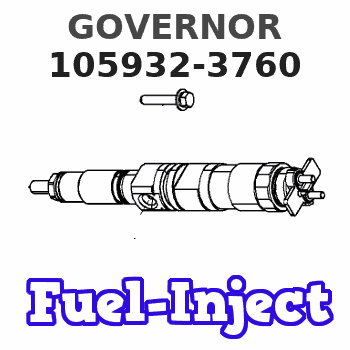

Information governor

BOSCH

F 019 Z5E 899

f019z5e899

ZEXEL

105932-3760

1059323760

ISUZU

1157901660

1157901660

Rating:

Scheme ###:

| 1. | [1] | 159200-7220 | GOVERNOR HOUSING |

| 2. | [1] | 154007-0200 | ADAPTOR |

| 3. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 4. | [1] | 159232-2620 | PLATE |

| 5. | [5] | 029010-6810 | BLEEDER SCREW |

| 5B. | [1] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 7. | [1] | 139710-0200 | O-RING |

| 8. | [1] | 159205-2321 | LEVER SHAFT |

| 9. | [1] | 159202-7800 | CONTROL LEVER |

| 10. | [1] | 016010-0810 | LOCKING WASHER |

| 11/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 11/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 11/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 11/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 11/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 11/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 11/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 11/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 11/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 12. | [1] | 159215-0000 | COILED SPRING |

| 13. | [1] | 159242-6601 | CONTROL LEVER |

| 15. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 16. | [1] | 159237-5500 | CAPSULE |

| 17. | [1] | 159202-5320 | CONTROL LEVER |

| 18. | [1] | 159215-0300 | COILED SPRING |

| 20. | [1] | 159242-0220 | CONTROL LEVER |

| 21. | [1] | 029311-0210 | SHIM D14&10.1T1 |

| 22. | [1] | 139610-0700 | PACKING RING |

| 23/1. | [0] | 139410-3800 | SHIM D22&10.2T0.2 |

| 23/1. | [0] | 139410-3900 | SHIM D22&10.2T0.3 |

| 23/1. | [0] | 139410-4000 | SHIM D22&10.2T0.4 |

| 23/1. | [0] | 139410-4100 | SHIM D22&10.2T0.6 |

| 23/1. | [0] | 139410-4200 | SHIM D22&10.2T0.8 |

| 24. | [1] | 159215-7200 | COILED SPRING |

| 25. | [1] | 159235-6500 | CAP |

| 26. | [1] | 159290-8020 | CONTROL LEVER |

| 27. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 35. | [1] | 159255-4920 | GOVERNOR COVER |

| 35/1. | [1] | 159301-8020 | GOVERNOR COVER |

| 35/1/1. | [1] | 159301-7920 | GOVERNOR COVER |

| 35/1/1/4. | [1] | 159230-2800 | BUSHING |

| 35/1/2. | [1] | 159252-4420 | LEVER GROUP |

| 35/1/2/1. | [1] | 159202-2200 | CONTROL LEVER |

| 35/1/2/2. | [1] | 016010-0810 | LOCKING WASHER |

| 35/1/2/3. | [1] | 159202-2120 | CONTROL LEVER |

| 35/1/2/4. | [1] | 016010-0810 | LOCKING WASHER |

| 35/1/2/5. | [1] | 159215-2301 | COILED SPRING |

| 35/1/2/6. | [1] | 159205-6320 | LEVER SHAFT |

| 35/1/3. | [1] | 139411-0600 | SHIM |

| 35/1/4. | [1] | 159238-3000 | LOCKING WASHER |

| 35/1/5. | [1] | 139610-0600 | PACKING RING |

| 35/2. | [1] | 159205-0400 | LEVER SHAFT |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/4. | [1] | 159253-2320 | TENSIONING LEVER |

| 35/4/2. | [1] | 159204-5021 | RACK |

| 35/4/3. | [1] | 159233-0300 | UNION NUT |

| 35/4/4. | [1] | 159234-0300 | FLAT-HEAD SCREW |

| 35/4/5. | [1] | 159216-0000 | COILED SPRING |

| 35/4/6. | [1] | 159216-0100 | COILED SPRING |

| 35/5. | [1] | 159203-7020 | GUIDE LEVER |

| 35/6. | [2] | 159235-5000 | BUSHING |

| 35/7. | [1] | 159215-1701 | COILED SPRING |

| 35/8. | [1] | 159231-1300 | BEARING PIN |

| 35/9. | [2] | 016010-0610 | LOCKING WASHER |

| 35/10. | [1] | 159238-2900 | BUSHING |

| 51. | [6] | 020106-3840 | BLEEDER SCREW |

| 51B. | [1] | 159229-9300 | BLEEDER SCREW |

| 52. | [1] | 014110-6440 | LOCKING WASHER |

| 65. | [1] | 154613-0720 | RACK SENSOR ASSY |

| 65/1. | [1] | 407945-0540 | RACK SENSOR |

| 65/2. | [1] | 154390-4000 | GASKET |

| 65/3. | [2] | 020106-1670 | BLEEDER SCREW |

| 100. | [1] | 154100-9520 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 110. | [1] | 154123-2320 | SLIDING PIECE |

| 111/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 111/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 111/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 111/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 111/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 111/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 111/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 111/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 111/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 112. | [1] | 159236-0200 | TERMINAL STUD |

| 130. | [1] | 159217-1100 | GOVERNOR SPRING |

| 131. | [1] | 159211-3400 | GOVERNOR SPRING |

| 132. | [1] | 159214-0000 | COILED SPRING |

| 133. | [1] | 159219-4920 | SPRING PACK |

| 133/1. | [1] | 159234-5602 | GUIDE SLEEVE |

| 133/2. | [1] | 159212-3300 | COILED SPRING |

| 133/3. | [1] | 159219-1400 | COILED SPRING |

| 133/4/1. | [0] | 029310-9240 | SHIM D11.9&9T0.1 |

| 133/4/1. | [0] | 029310-9250 | SHIM D11.9&9T0.2 |

| 133/4/1. | [0] | 029310-9260 | SHIM D11.9&9T0.25 |

| 133/4/1. | [0] | 029310-9270 | SHIM D11.9&9T1.0 |

| 133/4/1. | [0] | 139409-0100 | SHIM D11.9&9T0.3 |

| 133/4/1. | [0] | 139409-0200 | SHIM D11.9&9T0.5 |

| 133/4/1. | [0] | 139409-0300 | SHIM D11.5&9T0.8 |

| 135. | [1] | 159248-2700 | FLAT-HEAD SCREW |

| 137. | [1] | 159237-5300 | CAPSULE |

| 140. | [1] | 159205-2101 | LEVER SHAFT |

| 145. | [1] | 159233-5700 | UNION NUT |

| 149. | [1] | 159237-5400 | CAPSULE |

| 150. | [1] | 159235-5300 | SLOTTED WASHER |

| 155. | [1] | 159204-7720 | STRAP |

| 156. | [1] | 159233-0520 | BLEEDER SCREW |

| 158. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 170. | [1] | 159295-1421 | CONTROL LEVER |

| 171. | [1] | 014110-8440 | LOCKING WASHER |

| 172. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 173/1. | [1] | 139006-7700 | BLEEDER SCREW |

| 173/1. | [1] | 139006-7800 | BLEEDER SCREW |

| 173/1. | [1] | 139006-7900 | BLEEDER SCREW |

| 173/1. | [1] | 139006-8000 | BLEEDER SCREW |

| 173/1. | [1] | 139006-8100 | BLEEDER SCREW |

| 173/1. | [1] | 139006-8200 | BLEEDER SCREW |

| 173/1. | [1] | 139006-8300 | BLEEDER SCREW |

| 174. | [1] | 154012-5500 | BLEEDER SCREW |

| 175. | [1] | 154012-5300 | FLAT-HEAD SCREW M8P1.25L55 |

| 176. | [1] | 159233-7500 | UNION NUT |

| 177. | [1] | 154011-2300 | UNION NUT |

| 178. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 236. | [1] | 154390-1300 | GASKET |

| 237. | [1] | 159238-3100 | GASKET |

| 250. | [1] | 159228-4920 | BRACKET |

| 251. | [2] | 154332-9900 | COILED SPRING |

| 252. | [1] | 159248-0200 | BLEEDER SCREW |

| 257. | [2] | 154156-0600 | TUBE |

| 300. | [1] | 159310-2800 | CAM PLATE |

| 301. | [1] | 016010-0840 | LOCKING WASHER |

| 303. | [1] | 016010-0540 | LOCKING WASHER |

| 311. | [1] | 159237-0200 | CAPSULE |

| 835S. | [1] | 154062-1900 | CAP D12L24 |

| 836S. | [1] | 154062-1700 | CAP D20L32 |

Include in #1:

101606-0490

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Maintenance

Every 20,000 miles (30,000 km) or 1,000 hours, clean the oil drain pipe from turbocharger to sump, also turbocharger compressor wheel and cover.

T1Remove the air inlet duct and compressor housing and check for dirt or dust build-up (see Fig. T.1).Remove all foreign matter - determine and correct cause of build up.Use soft brush on compressor wheel as uneven deposits can affect rotor balance and cause bearing failure.With the compressor housing removed, push the compressor wheel towards the turbine wheel and turn rotating assembly by hand: check for binding and rubbing. Listen carefully for unusual noises. If binding or rubbing is evident, remove the turbocharger for dismantling and inspection.To Remove Turbocharger

Disconnect turbocharger inlet and outlet connections.Disconnect exhaust pipe.Remove oil supply pipe and release oil drain pipe.Release turbocharger outlet assembly from the cylinder block.

T2Remove turbocharger from exhaust manifold, (see Fig. T.2).Seal open engine connections.Airesearch T-31 (see Fig. T.3)

T3Dismantling

Clean the exterior with a pressure spray of a non-caustic cleaning solvent before dismantling. Dismantle only as required to make necessary inspection or repairs. Note: The 'Wastegate' unit where fitted, cannot be dismantled. See page T.4 for service/calibration instructions. As each part is removed, place in a clean container to prevent loss or damage.Remove the bolts, clamps and lockplates which hold the compressor and turbine housings to the centre housing group. Tap the housings with a soft faced hammer if force is needed for removal. Exercise caution when removing housings to prevent damage to compressor or turbine wheel. Once damaged, they cannot be repaired. Never attempt to straighten bent compressor or turbine blades-replace the faulty component.Place the centre housing group in a suitable holding fixture which will prevent the turbine wheel from turning.Use a T-handled wrench when removing the compressor wheel locknut to avoid possible bending of the shaft.Lift the compressor wheel off the shaft. Remove the shaft wheel from the centre housing keeping shaft central with bearings until clear of centre housing. The turbine wheel shroud is not retained to the centre housing and will fall free when the shaft wheel is removed.Remove lockplates and bolts from back plate.Tap backplate with soft mallet to remove from recess in centre housing.Remove thrust collar and thrust bearing from centre housing.Remove bearings and retainers from centre housing. Discard rubber sealing ring.Cleaning

Before cleaning, inspect all parts for signs of rubbing, burning or other damage which might not be evident after cleaning.Soak all parts in clean non-caustic carbon solvent. After soaking, use a stiff bristle brush and remove all dirt particles. Dry parts thoroughly. Normally a light accumulation of carbon deposits will not affect turbine operation.Internal Parts Inspection (see Fig. T.4)

T4Parts must now show signs of damage, corrosion or deterioration. Threads must not be nicked, crossed or stripped.The turbine wheel must show no signs of rubbing and vanes must not be torn or worn to a feather edge. The shaft must show little signs of scoring, scratches or seizure with the bearings.The compressor must show no signs of rubbing or damage from foreign matter. The compressor wheel

Every 20,000 miles (30,000 km) or 1,000 hours, clean the oil drain pipe from turbocharger to sump, also turbocharger compressor wheel and cover.

T1Remove the air inlet duct and compressor housing and check for dirt or dust build-up (see Fig. T.1).Remove all foreign matter - determine and correct cause of build up.Use soft brush on compressor wheel as uneven deposits can affect rotor balance and cause bearing failure.With the compressor housing removed, push the compressor wheel towards the turbine wheel and turn rotating assembly by hand: check for binding and rubbing. Listen carefully for unusual noises. If binding or rubbing is evident, remove the turbocharger for dismantling and inspection.To Remove Turbocharger

Disconnect turbocharger inlet and outlet connections.Disconnect exhaust pipe.Remove oil supply pipe and release oil drain pipe.Release turbocharger outlet assembly from the cylinder block.

T2Remove turbocharger from exhaust manifold, (see Fig. T.2).Seal open engine connections.Airesearch T-31 (see Fig. T.3)

T3Dismantling

Clean the exterior with a pressure spray of a non-caustic cleaning solvent before dismantling. Dismantle only as required to make necessary inspection or repairs. Note: The 'Wastegate' unit where fitted, cannot be dismantled. See page T.4 for service/calibration instructions. As each part is removed, place in a clean container to prevent loss or damage.Remove the bolts, clamps and lockplates which hold the compressor and turbine housings to the centre housing group. Tap the housings with a soft faced hammer if force is needed for removal. Exercise caution when removing housings to prevent damage to compressor or turbine wheel. Once damaged, they cannot be repaired. Never attempt to straighten bent compressor or turbine blades-replace the faulty component.Place the centre housing group in a suitable holding fixture which will prevent the turbine wheel from turning.Use a T-handled wrench when removing the compressor wheel locknut to avoid possible bending of the shaft.Lift the compressor wheel off the shaft. Remove the shaft wheel from the centre housing keeping shaft central with bearings until clear of centre housing. The turbine wheel shroud is not retained to the centre housing and will fall free when the shaft wheel is removed.Remove lockplates and bolts from back plate.Tap backplate with soft mallet to remove from recess in centre housing.Remove thrust collar and thrust bearing from centre housing.Remove bearings and retainers from centre housing. Discard rubber sealing ring.Cleaning

Before cleaning, inspect all parts for signs of rubbing, burning or other damage which might not be evident after cleaning.Soak all parts in clean non-caustic carbon solvent. After soaking, use a stiff bristle brush and remove all dirt particles. Dry parts thoroughly. Normally a light accumulation of carbon deposits will not affect turbine operation.Internal Parts Inspection (see Fig. T.4)

T4Parts must now show signs of damage, corrosion or deterioration. Threads must not be nicked, crossed or stripped.The turbine wheel must show no signs of rubbing and vanes must not be torn or worn to a feather edge. The shaft must show little signs of scoring, scratches or seizure with the bearings.The compressor must show no signs of rubbing or damage from foreign matter. The compressor wheel