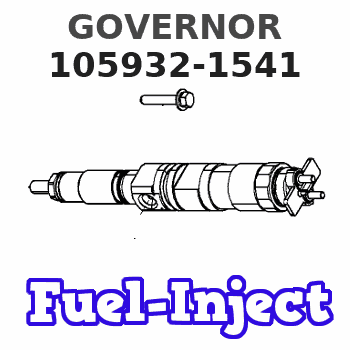

Information governor

BOSCH

9 420 611 063

9420611063

ZEXEL

105932-1541

1059321541

MITSUBISHI

ME742200

me742200

Rating:

Scheme ###:

| 1. | [1] | 159200-4220 | GOVERNOR HOUSING |

| 2. | [1] | 154007-0200 | ADAPTOR |

| 3. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 4. | [1] | 159232-0201 | PLATE |

| 5. | [5] | 029010-6810 | BLEEDER SCREW |

| 5B. | [1] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 7. | [1] | 016530-1010 | O-RING |

| 8. | [1] | 159205-2321 | LEVER SHAFT |

| 9. | [1] | 159202-5101 | CONTROL LEVER |

| 10. | [1] | 016010-0810 | LOCKING WASHER |

| 11/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 11/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 11/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 11/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 11/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 11/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 11/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 11/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 11/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 12. | [1] | 159215-0000 | COILED SPRING |

| 13. | [1] | 159242-6601 | CONTROL LEVER |

| 15. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 16. | [1] | 159237-5500 | CAPSULE |

| 17. | [1] | 159202-5320 | CONTROL LEVER |

| 18. | [1] | 159215-0300 | COILED SPRING |

| 20. | [1] | 159242-0220 | CONTROL LEVER |

| 21. | [1] | 159242-0600 | BUSHING |

| 22. | [1] | 016530-1010 | O-RING |

| 23/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 23/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 23/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 23/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 23/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 23/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 23/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 23/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 23/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 24. | [1] | 159215-2000 | COILED SPRING |

| 25. | [1] | 159235-5800 | CAP |

| 26. | [1] | 159249-6920 | CONTROL LEVER |

| 27. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 35. | [1] | 159251-8620 | GOVERNOR COVER |

| 35/1. | [1] | 159201-3422 | GOVERNOR COVER |

| 35/2. | [1] | 159205-0400 | LEVER SHAFT |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/4. | [1] | 159253-2220 | TENSIONING LEVER |

| 35/4/1. | [1] | 159203-1720 | TENSIONING LEVER |

| 35/4/1. | [1] | 159203-1720 | TENSIONING LEVER |

| 35/4/2. | [1] | 159204-5021 | RACK |

| 35/4/3. | [1] | 159233-0300 | UNION NUT |

| 35/4/4. | [1] | 159234-0300 | FLAT-HEAD SCREW |

| 35/4/5. | [1] | 159216-0000 | COILED SPRING |

| 35/4/6. | [1] | 159216-0100 | COILED SPRING |

| 35/5. | [1] | 159203-6120 | GUIDE LEVER |

| 35/7. | [1] | 159215-1701 | COILED SPRING |

| 35/8. | [1] | 159231-1300 | BEARING PIN |

| 35/9. | [2] | 016010-0610 | LOCKING WASHER |

| 35/10. | [1] | 159238-2900 | BUSHING |

| 51. | [7] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 154050-1720 | STOPPING DEVICE |

| 100. | [1] | 154100-9520 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 110. | [1] | 154123-2320 | SLIDING PIECE |

| 111/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 111/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 111/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 111/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 111/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 111/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 111/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 111/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 111/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 112. | [1] | 159236-0200 | TERMINAL STUD |

| 130. | [1] | 159210-0700 | GOVERNOR SPRING |

| 131. | [1] | 159211-1100 | GOVERNOR SPRING |

| 132. | [1] | 159214-0000 | COILED SPRING |

| 133. | [1] | 159212-5320 | SPRING PACK |

| 133/1. | [1] | 159234-5602 | GUIDE SLEEVE |

| 133/2. | [1] | 159212-5000 | COILED SPRING |

| 133/3. | [1] | 159212-5300 | COILED SPRING |

| 133/4/1. | [0] | 029310-9240 | SHIM D11.9&9T0.1 |

| 133/4/1. | [0] | 029310-9250 | SHIM D11.9&9T0.2 |

| 133/4/1. | [0] | 029310-9260 | SHIM D11.9&9T0.25 |

| 133/4/1. | [0] | 029310-9270 | SHIM D11.9&9T1.0 |

| 133/4/1. | [0] | 139409-0100 | SHIM D11.9&9T0.3 |

| 133/4/1. | [0] | 139409-0200 | SHIM D11.9&9T0.5 |

| 133/4/1. | [0] | 139409-0300 | SHIM D11.5&9T0.8 |

| 135. | [1] | 159248-2700 | FLAT-HEAD SCREW |

| 137. | [1] | 159237-5300 | CAPSULE |

| 140. | [1] | 159205-2101 | LEVER SHAFT |

| 145. | [1] | 159233-5700 | UNION NUT |

| 149. | [1] | 159237-5400 | CAPSULE |

| 150. | [1] | 159235-5300 | SLOTTED WASHER |

| 155. | [1] | 159204-5120 | STRAP |

| 156. | [1] | 159233-0520 | BLEEDER SCREW |

| 158. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 160. | [1] | 159252-0821 | LEVER GROUP |

| 160/1. | [1] | 159202-2200 | CONTROL LEVER |

| 160/2. | [1] | 016010-0810 | LOCKING WASHER |

| 160/3. | [1] | 159202-2120 | CONTROL LEVER |

| 160/4. | [1] | 016010-0810 | LOCKING WASHER |

| 160/5. | [1] | 159215-2301 | COILED SPRING |

| 160/7. | [1] | 159205-2222 | LEVER SHAFT |

| 168/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 168/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 168/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 168/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 168/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 168/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 168/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 168/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 168/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 168/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 168/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 169. | [1] | 139410-2300 | SHIM |

| 170. | [1] | 159267-8520 | CONTROL LEVER |

| 172. | [1] | 159231-4400 | UNION NUT |

| 173/1. | [1] | 139006-3500 | BLEEDER SCREW M6P1.0L33 |

| 173/1. | [1] | 139006-3700 | BLEEDER SCREW M6P1.0L34 |

| 173/1. | [1] | 139006-3800 | BLEEDER SCREW M6P1.0L35 |

| 173/1. | [1] | 139006-3900 | BLEEDER SCREW M6P1.0L36 |

| 173/1. | [1] | 139006-5300 | BLEEDER SCREW M6P1.0L31 |

| 173/1. | [1] | 139006-5400 | BLEEDER SCREW M6P1.0L32 |

| 173/1. | [1] | 155615-2500 | BLEEDER SCREW M6P1.0L37 |

| 174. | [1] | 154010-8100 | BLEEDER SCREW M8P1.25L65 |

| 175. | [1] | 154010-2900 | BLEEDER SCREW |

| 176. | [1] | 159225-8600 | UNION NUT |

| 177. | [1] | 154011-2300 | UNION NUT |

| 178. | [1] | 154011-0100 | HEXAGON NUT |

| 180. | [2] | 154371-0000 | PLAIN WASHER |

| 180. | [2] | 154371-0000 | PLAIN WASHER |

| 181. | [1] | 159262-5520 | CONTROL LEVER |

| 182. | [1] | 029300-8010 | PLAIN WASHER D15&8T1.00 |

| 183. | [1] | 016010-0740 | LOCKING WASHER |

| 184. | [1] | 159215-4600 | COILED SPRING |

| 185. | [1] | 159229-7500 | CLAMPING BAND |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 159238-3100 | GASKET |

| 250. | [1] | 159229-2520 | BRACKET |

| 251. | [2] | 159243-9900 | COILED SPRING |

| 252. | [1] | 159248-0200 | BLEEDER SCREW |

| 253. | [1] | 139010-1000 | STUD |

| 257. | [2] | 154156-0500 | TUBE |

| 300. | [1] | 159288-1200 | CAM PLATE |

| 301. | [1] | 016010-0840 | LOCKING WASHER |

| 303. | [1] | 016010-0540 | LOCKING WASHER |

| 311. | [1] | 159237-0200 | CAPSULE |

| 340. | [1] | 159245-8300 | PLATE |

| 341. | [2] | 020104-1040 | BLEEDER SCREW |

Include in #1:

101608-1262

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

105932-1541

ME742200 MITSUBISHI

GOVERNOR

K 14JK MECHANICAL GOVERNOR GOV RLD GOV

K 14JK MECHANICAL GOVERNOR GOV RLD GOV

Information:

Introduction

Do not perform any procedure that is outlined in this Special Instruction until you have read and understand the information contained in this document.Required Parts

Table 1

Required Parts

Item Qty Part Number Part Name

1 1 360-9664 Tool Kit

2 1 399-7930 Cap Kit Testing Procedure

Use Caterpillar Electronic Technician (ET) to perform a "Manual Diesel Particulate Filter Regeneration".

Once the regeneration is complete, wait for the engine to drop to idle before shutting off the engine. The regeneration takes approximately 20 minutes.

Allow the system to cool down before handling.

While waiting for the exhaust to cool, perform the following actions.

Record the "Idle Speed Limit". Use Cat ET to change the "Idle RPM Limit" to 2100 rpm.

Use Cat ET to disable the automatic regeneration. A "Check Engine" light with active code 3714-31 will be present.

Remove the exhaust piping after the DPF. Install the 3 inch orifice plate for C13 and C15 engines. Install the 2 inch orifice plate for C7 and C9 engines. The 2 inch orifice plate is part of the 399-7930 Cap Kit .For a DPF with a dual outlet, use the solid cap that is provided and cap one of the outlets.For a dual DPF with one end cap, use a 313-3496 Plug to plug the drain hole, one 3L-7055 Pipe Connector , one 001-6449 Connector , and filter paper. Remove the delta P sensor from each DPF. Insert one 3L-7055 Pipe Connector , one 001-6449 Connector , and filter paper into each DPF. This action allows both diesel particulate filters to be tested at the same time.Note: The 313-3496 Plug , the 001-6449 Connector , and the 3L-7055 Pipe Connector is not included in the kit.

Start the engine. Run the engine at 2100 rpm for a minimum of 10 minutes to stabilize DPF temperatures.

Shut down the engine and install the filter holder in the drain port.Note: Do not wait more than 10 minutes after the engine has shut down to install the filter.

Run the engine at 2100 rpm for 20 minutes.

Shut down the engine and remove the filter holder. Use proper personal protective equipment to remove the filter holder.Note: Do not wait more than 10 minutes after the engine has shut down to remove the filter holder.

Warning: The filter holder will still be hot.

Wait for the filter holder to cool down before disassembly.

Carefully disassemble the filter holder to prevent contamination.

Tip the fitting over on a clean surface to remove the filter paper.

Handle the filter paper with clean hands. Only handle the filter paper by the edges.

Compare the stained area in the center of the filter paper to the color coded sheet that is provided.If the stained area of the filter paper is as dark or darker than colored circle 2, then the DPF may have to be replaced.If a DPF fails the test, then contact the DPF hotline to verify the failure and have a new DPF released.

Do not perform any procedure that is outlined in this Special Instruction until you have read and understand the information contained in this document.Required Parts

Table 1

Required Parts

Item Qty Part Number Part Name

1 1 360-9664 Tool Kit

2 1 399-7930 Cap Kit Testing Procedure

Use Caterpillar Electronic Technician (ET) to perform a "Manual Diesel Particulate Filter Regeneration".

Once the regeneration is complete, wait for the engine to drop to idle before shutting off the engine. The regeneration takes approximately 20 minutes.

Allow the system to cool down before handling.

While waiting for the exhaust to cool, perform the following actions.

Record the "Idle Speed Limit". Use Cat ET to change the "Idle RPM Limit" to 2100 rpm.

Use Cat ET to disable the automatic regeneration. A "Check Engine" light with active code 3714-31 will be present.

Remove the exhaust piping after the DPF. Install the 3 inch orifice plate for C13 and C15 engines. Install the 2 inch orifice plate for C7 and C9 engines. The 2 inch orifice plate is part of the 399-7930 Cap Kit .For a DPF with a dual outlet, use the solid cap that is provided and cap one of the outlets.For a dual DPF with one end cap, use a 313-3496 Plug to plug the drain hole, one 3L-7055 Pipe Connector , one 001-6449 Connector , and filter paper. Remove the delta P sensor from each DPF. Insert one 3L-7055 Pipe Connector , one 001-6449 Connector , and filter paper into each DPF. This action allows both diesel particulate filters to be tested at the same time.Note: The 313-3496 Plug , the 001-6449 Connector , and the 3L-7055 Pipe Connector is not included in the kit.

Start the engine. Run the engine at 2100 rpm for a minimum of 10 minutes to stabilize DPF temperatures.

Shut down the engine and install the filter holder in the drain port.Note: Do not wait more than 10 minutes after the engine has shut down to install the filter.

Run the engine at 2100 rpm for 20 minutes.

Shut down the engine and remove the filter holder. Use proper personal protective equipment to remove the filter holder.Note: Do not wait more than 10 minutes after the engine has shut down to remove the filter holder.

Warning: The filter holder will still be hot.

Wait for the filter holder to cool down before disassembly.

Carefully disassemble the filter holder to prevent contamination.

Tip the fitting over on a clean surface to remove the filter paper.

Handle the filter paper with clean hands. Only handle the filter paper by the edges.

Compare the stained area in the center of the filter paper to the color coded sheet that is provided.If the stained area of the filter paper is as dark or darker than colored circle 2, then the DPF may have to be replaced.If a DPF fails the test, then contact the DPF hotline to verify the failure and have a new DPF released.