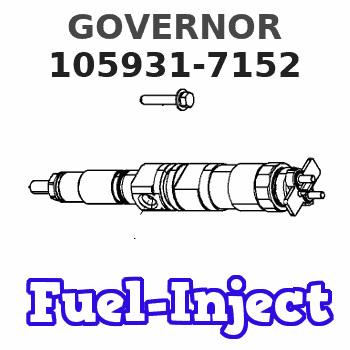

Information governor

BOSCH

9 420 613 602

9420613602

ZEXEL

105931-7152

1059317152

MITSUBISHI

ME730361

me730361

Rating:

Scheme ###:

| 1. | [1] | 159200-4220 | GOVERNOR HOUSING |

| 2. | [1] | 154007-0200 | ADAPTOR |

| 3. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 4. | [1] | 159232-2620 | PLATE |

| 5. | [5] | 029010-6810 | BLEEDER SCREW |

| 5B. | [1] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 7. | [1] | 016530-1010 | O-RING |

| 8. | [1] | 159205-2321 | LEVER SHAFT |

| 9. | [1] | 159202-5101 | CONTROL LEVER |

| 10. | [1] | 016010-0810 | LOCKING WASHER |

| 11/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 11/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 11/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 11/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 11/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 11/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 11/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 11/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 11/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 12. | [1] | 159215-0000 | COILED SPRING |

| 13. | [1] | 159242-6601 | CONTROL LEVER |

| 15. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 16. | [1] | 159237-5500 | CAPSULE |

| 17. | [1] | 159202-5320 | CONTROL LEVER |

| 18. | [1] | 159215-0300 | COILED SPRING |

| 20. | [1] | 159242-0220 | CONTROL LEVER |

| 21. | [1] | 159242-0600 | BUSHING |

| 22. | [1] | 016530-1010 | O-RING |

| 23/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 23/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 23/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 23/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 23/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 23/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 23/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 23/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 23/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 24. | [1] | 159215-2000 | COILED SPRING |

| 25. | [1] | 159235-5800 | CAP |

| 26. | [1] | 159249-6920 | CONTROL LEVER |

| 27. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 35. | [1] | 159251-8620 | GOVERNOR COVER |

| 35/1. | [1] | 159201-3422 | GOVERNOR COVER |

| 35/2. | [1] | 159205-0400 | LEVER SHAFT |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/4. | [1] | 159253-2220 | TENSIONING LEVER |

| 35/4/1. | [1] | 159203-1720 | TENSIONING LEVER |

| 35/4/2. | [1] | 159204-5021 | RACK |

| 35/4/3. | [1] | 159233-0300 | UNION NUT |

| 35/4/4. | [1] | 159234-0300 | FLAT-HEAD SCREW |

| 35/4/5. | [1] | 159216-0000 | COILED SPRING |

| 35/4/6. | [1] | 159216-0100 | COILED SPRING |

| 35/5. | [1] | 159203-6120 | GUIDE LEVER |

| 35/7. | [1] | 159215-1701 | COILED SPRING |

| 35/8. | [1] | 159231-1300 | BEARING PIN |

| 35/9. | [2] | 016010-0610 | LOCKING WASHER |

| 35/10. | [1] | 159238-2900 | BUSHING |

| 51. | [6] | 020106-3840 | BLEEDER SCREW |

| 51B. | [1] | 020106-4040 | BLEEDER SCREW |

| 65. | [1] | 154050-1720 | STOPPING DEVICE |

| 100. | [1] | 154100-9520 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 110. | [1] | 154123-2320 | SLIDING PIECE |

| 111/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 111/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 111/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 111/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 111/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 111/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 111/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 111/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 111/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 112. | [1] | 159236-0200 | TERMINAL STUD |

| 130. | [1] | 159210-2700 | COILED SPRING |

| 131. | [1] | 159211-3000 | GOVERNOR SPRING |

| 132. | [1] | 159214-0100 | COILED SPRING |

| 133. | [1] | 159212-4720 | SPRING PACK |

| 133/1. | [1] | 159234-5602 | GUIDE SLEEVE |

| 133/2. | [1] | 159212-4700 | COILED SPRING |

| 133/3. | [1] | 159212-4600 | COILED SPRING |

| 133/4/1. | [0] | 029310-9240 | SHIM D11.9&9T0.1 |

| 133/4/1. | [0] | 029310-9250 | SHIM D11.9&9T0.2 |

| 133/4/1. | [0] | 029310-9260 | SHIM D11.9&9T0.25 |

| 133/4/1. | [0] | 029310-9270 | SHIM D11.9&9T1.0 |

| 133/4/1. | [0] | 139409-0100 | SHIM D11.9&9T0.3 |

| 133/4/1. | [0] | 139409-0200 | SHIM D11.9&9T0.5 |

| 133/4/1. | [0] | 139409-0300 | SHIM D11.5&9T0.8 |

| 135. | [1] | 159248-2700 | FLAT-HEAD SCREW |

| 137. | [1] | 159237-5300 | CAPSULE |

| 140. | [1] | 159205-2101 | LEVER SHAFT |

| 145. | [1] | 159233-5700 | UNION NUT |

| 149. | [1] | 159237-5400 | CAPSULE |

| 150. | [1] | 159235-5300 | SLOTTED WASHER |

| 155. | [1] | 159204-7720 | STRAP |

| 156. | [1] | 159233-0520 | BLEEDER SCREW |

| 158. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 160. | [1] | 159252-0821 | LEVER GROUP |

| 160/1. | [1] | 159202-2200 | CONTROL LEVER |

| 160/2. | [1] | 016010-0810 | LOCKING WASHER |

| 160/3. | [1] | 159202-2120 | CONTROL LEVER |

| 160/4. | [1] | 016010-0810 | LOCKING WASHER |

| 160/5. | [1] | 159215-2301 | COILED SPRING |

| 160/7. | [1] | 159205-2222 | LEVER SHAFT |

| 168/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 168/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 168/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 168/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 168/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 168/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 168/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 168/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 168/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 168/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 168/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 169. | [1] | 139410-2300 | SHIM |

| 170. | [1] | 159264-3220 | CONTROL LEVER |

| 172. | [1] | 159231-4400 | UNION NUT |

| 173/1. | [1] | 139006-3500 | BLEEDER SCREW M6P1.0L33 |

| 173/1. | [1] | 139006-3700 | BLEEDER SCREW M6P1.0L34 |

| 173/1. | [1] | 139006-3800 | BLEEDER SCREW M6P1.0L35 |

| 173/1. | [1] | 139006-3900 | BLEEDER SCREW M6P1.0L36 |

| 173/1. | [1] | 139006-5300 | BLEEDER SCREW M6P1.0L31 |

| 173/1. | [1] | 139006-5400 | BLEEDER SCREW M6P1.0L32 |

| 173/1. | [1] | 155615-2500 | BLEEDER SCREW M6P1.0L37 |

| 174. | [1] | 154010-7200 | BLEEDER SCREW M8P1.25L62 |

| 175. | [1] | 154010-2900 | BLEEDER SCREW |

| 176. | [1] | 159225-8600 | UNION NUT |

| 177. | [1] | 154011-2300 | UNION NUT |

| 178. | [1] | 154011-0100 | HEXAGON NUT |

| 180. | [2] | 154371-0000 | PLAIN WASHER |

| 180. | [2] | 154371-0000 | PLAIN WASHER |

| 181. | [1] | 159262-5520 | CONTROL LEVER |

| 182. | [1] | 029300-8010 | PLAIN WASHER D15&8T1.00 |

| 183. | [1] | 016010-0740 | LOCKING WASHER |

| 184. | [1] | 159215-4600 | COILED SPRING |

| 185. | [1] | 159229-7500 | CLAMPING BAND |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 159238-3100 | GASKET |

| 250. | [1] | 159229-2520 | BRACKET |

| 251. | [2] | 159243-9900 | COILED SPRING |

| 252. | [1] | 159248-0200 | BLEEDER SCREW |

| 253. | [1] | 139010-1000 | STUD |

| 257. | [2] | 154156-0500 | TUBE |

| 300. | [1] | 159282-0500 | CAM PLATE |

| 301. | [1] | 016010-0840 | LOCKING WASHER |

| 303. | [1] | 016010-0540 | LOCKING WASHER |

| 311. | [1] | 159237-0200 | CAPSULE |

| 340. | [1] | 159245-8300 | PLATE |

| 341. | [2] | 020104-1040 | BLEEDER SCREW |

| 350. | [1] | 159227-7800 | BRACKET |

| 351. | [1] | 020118-1440 | BLEEDER SCREW |

| 352. | [2] | 020106-1240 | BLEEDER SCREW M6P1.0L12 |

| 353. | [1] | 159225-5120 | PLATE |

| 354. | [1] | 020106-0840 | BLEEDER SCREW |

| 835S. | [1] | 154062-1900 | CAP D12L24 |

| 836S. | [1] | 154062-1700 | CAP D20L32 |

Include in #1:

101607-1250

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Fuel System Information

Use only fuel as recommended in this section.

Fill the fuel tank at the end of each day of operation to drive out moist air and to prevent condensation. Do not fill the tank to the top. Fuel expands as it gets warm and may overflow. Do not fill the fuel filters with fuel before installing them. Contaminated fuel will cause accelerated wear to the fuel system parts.

Fuel Tanks

Drain the water and sediment from any fuel storage tank weekly, at the oil change period, and before it is refilled. This will help prevent water and/or sediment from being pumped from the fuel storage tank into the engine fuel tank.Fuel tanks should contain some provision for draining water and sediment from the bottom of the fuel tanks. Some fuel tanks use supply pipes that allow water and sediment to settle below the end of the fuel supply pipe. This water and sediment should be drained at each oil change. Do not use fuel tanks with supply lines that take fuel directly from the bottom of the tank.Fuel Lines

The fuel return line should deposit fuel at the top of the tank opposite the supply connection. This allows the engine to get warm (not hot) fuel from the tank. It also allows air to escape from the return fuel without being pulled back into the engine. If hot fuel must return to the tank, a fuel cooler is required.Avoid sharp angles and use as few fittings and connections as possible. Moisture in the fuel will tend to collect and freeze at low points in the fuel lines. Fuel lines should travel the most direct route to the engine compartment.Do not use galvanized fittings in the fuel lines. Size fuel lines so they do not exceed maximum fuel transfer pump inlet restriction and fuel return line restriction specifications.Fuel Filters

A primary fuel filter and/or water separator is recommended and should be installed between the fuel tank and the engine fuel inlet.After changing the fuel filter(s), always prime the fuel system (if equipped with a priming pump) to remove air bubbles from the system.Fuel Recommendations

Caterpillar Diesel Engines are capable of burning a wide range of distillate fuels. The use of clean, stable blends of distillate fuel which meet the following requirements will provide quality engine service life. The fuels recommended for use in Caterpillar engines are normally No.2-D diesel fuel and No.2 fuel oil, although No. 1 grades are acceptable. The following fuel specifications are some of the worldwide fuels which also meet the requirements. The following fuel characteristics should be considered when procuring fuel for use in Caterpillar diesel engines.Cetane Number

The minimum cetane number required for average starting conditions for the direct injection engine is 40. A higher cetane value may be required for high altitude operation or cold weather starting.Filterability

Clean fuels should have no more than 0.1% of sediment and water. Storage of fuel for extended periods of time can cause fuel oxidation with solids forming, causing filtering problems.Pour Point

The pour

Use only fuel as recommended in this section.

Fill the fuel tank at the end of each day of operation to drive out moist air and to prevent condensation. Do not fill the tank to the top. Fuel expands as it gets warm and may overflow. Do not fill the fuel filters with fuel before installing them. Contaminated fuel will cause accelerated wear to the fuel system parts.

Fuel Tanks

Drain the water and sediment from any fuel storage tank weekly, at the oil change period, and before it is refilled. This will help prevent water and/or sediment from being pumped from the fuel storage tank into the engine fuel tank.Fuel tanks should contain some provision for draining water and sediment from the bottom of the fuel tanks. Some fuel tanks use supply pipes that allow water and sediment to settle below the end of the fuel supply pipe. This water and sediment should be drained at each oil change. Do not use fuel tanks with supply lines that take fuel directly from the bottom of the tank.Fuel Lines

The fuel return line should deposit fuel at the top of the tank opposite the supply connection. This allows the engine to get warm (not hot) fuel from the tank. It also allows air to escape from the return fuel without being pulled back into the engine. If hot fuel must return to the tank, a fuel cooler is required.Avoid sharp angles and use as few fittings and connections as possible. Moisture in the fuel will tend to collect and freeze at low points in the fuel lines. Fuel lines should travel the most direct route to the engine compartment.Do not use galvanized fittings in the fuel lines. Size fuel lines so they do not exceed maximum fuel transfer pump inlet restriction and fuel return line restriction specifications.Fuel Filters

A primary fuel filter and/or water separator is recommended and should be installed between the fuel tank and the engine fuel inlet.After changing the fuel filter(s), always prime the fuel system (if equipped with a priming pump) to remove air bubbles from the system.Fuel Recommendations

Caterpillar Diesel Engines are capable of burning a wide range of distillate fuels. The use of clean, stable blends of distillate fuel which meet the following requirements will provide quality engine service life. The fuels recommended for use in Caterpillar engines are normally No.2-D diesel fuel and No.2 fuel oil, although No. 1 grades are acceptable. The following fuel specifications are some of the worldwide fuels which also meet the requirements. The following fuel characteristics should be considered when procuring fuel for use in Caterpillar diesel engines.Cetane Number

The minimum cetane number required for average starting conditions for the direct injection engine is 40. A higher cetane value may be required for high altitude operation or cold weather starting.Filterability

Clean fuels should have no more than 0.1% of sediment and water. Storage of fuel for extended periods of time can cause fuel oxidation with solids forming, causing filtering problems.Pour Point

The pour