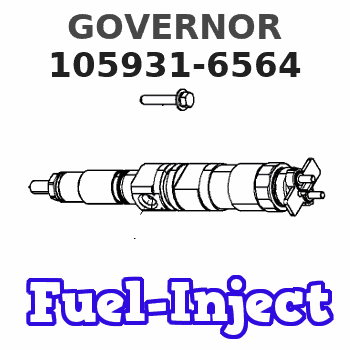

Information governor

BOSCH

9 420 612 655

9420612655

ZEXEL

105931-6564

1059316564

ISUZU

1157704950

1157704950

Rating:

Scheme ###:

| 1. | [1] | 159200-5020 | GOVERNOR HOUSING |

| 2. | [1] | 154007-0200 | ADAPTOR |

| 3. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 4. | [1] | 159232-0201 | PLATE |

| 5. | [5] | 029010-6810 | BLEEDER SCREW |

| 5B. | [1] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 7. | [1] | 139710-0200 | O-RING |

| 8. | [1] | 159205-2321 | LEVER SHAFT |

| 9. | [1] | 159202-5101 | CONTROL LEVER |

| 10. | [1] | 016010-0810 | LOCKING WASHER |

| 11/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 11/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 11/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 11/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 11/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 11/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 11/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 11/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 11/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 12. | [1] | 159215-0000 | COILED SPRING |

| 13. | [1] | 159242-6601 | CONTROL LEVER |

| 15. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 16. | [1] | 159237-5500 | CAPSULE |

| 17. | [1] | 159202-5220 | CONTROL LEVER |

| 18. | [1] | 159215-0300 | COILED SPRING |

| 20. | [1] | 159242-0220 | CONTROL LEVER |

| 21. | [1] | 029311-0210 | SHIM D14&10.1T1 |

| 22. | [1] | 139610-0700 | PACKING RING |

| 23/1. | [0] | 139411-0700 | SHIM D22&11T0.7 |

| 23/1. | [0] | 153305-0100 | SHIM D22&11T0.5 |

| 23/1. | [0] | 153305-0200 | SHIM D22&11T0.4 |

| 23/1. | [0] | 153305-0300 | SHIM D22&11T0.3 |

| 23/1. | [0] | 153305-0400 | SHIM D22&11T0.25 |

| 23/1. | [0] | 153305-0500 | SHIM D22&11T1.0 |

| 23/1. | [0] | 153305-0600 | SHIM D22&11T1.1 |

| 23/1. | [0] | 153305-0700 | SHIM D22&11T2.0 |

| 23/1. | [0] | 153305-1300 | SHIM D22&11T0.951 |

| 23/1. | [0] | 153305-1400 | SHIM D22&11T0.95 |

| 24. | [1] | 159215-3400 | COILED SPRING |

| 25. | [1] | 159235-5800 | CAP |

| 26. | [1] | 159249-6400 | CONTROL LEVER |

| 27. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 35. | [1] | 159250-0220 | GOVERNOR COVER |

| 35/1. | [1] | 159201-8420 | GOVERNOR COVER |

| 35/2. | [1] | 159205-0400 | LEVER SHAFT |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/4. | [1] | 159253-2320 | TENSIONING LEVER |

| 35/4/2. | [1] | 159204-5021 | RACK |

| 35/4/3. | [1] | 159233-0300 | UNION NUT |

| 35/4/4. | [1] | 159234-0300 | FLAT-HEAD SCREW |

| 35/4/5. | [1] | 159216-0000 | COILED SPRING |

| 35/4/6. | [1] | 159216-0100 | COILED SPRING |

| 35/5. | [1] | 159203-5320 | GUIDE LEVER |

| 35/6. | [2] | 159235-5000 | BUSHING |

| 35/7. | [1] | 159215-1701 | COILED SPRING |

| 35/8. | [1] | 159231-1300 | BEARING PIN |

| 35/9. | [2] | 016010-0610 | LOCKING WASHER |

| 35/10. | [1] | 159238-2900 | BUSHING |

| 51. | [7] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 155404-5700 | CAP |

| 100. | [1] | 154100-9520 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 110. | [1] | 154123-2320 | SLIDING PIECE |

| 111/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 111/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 111/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 111/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 111/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 111/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 111/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 111/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 111/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 112. | [1] | 159236-0200 | TERMINAL STUD |

| 130. | [1] | 159210-3200 | GOVERNOR SPRING |

| 131. | [1] | 159211-2200 | GOVERNOR SPRING |

| 132. | [1] | 159214-0000 | COILED SPRING |

| 133. | [1] | 159212-6620 | SPRING PACK |

| 133/1. | [1] | 159234-5602 | GUIDE SLEEVE |

| 133/2. | [1] | 159212-5500 | COILED SPRING |

| 133/3. | [1] | 159212-5200 | COILED SPRING |

| 133/4/1. | [0] | 029310-9240 | SHIM D11.9&9T0.1 |

| 133/4/1. | [0] | 029310-9250 | SHIM D11.9&9T0.2 |

| 133/4/1. | [0] | 029310-9260 | SHIM D11.9&9T0.25 |

| 133/4/1. | [0] | 029310-9270 | SHIM D11.9&9T1.0 |

| 133/4/1. | [0] | 139409-0100 | SHIM D11.9&9T0.3 |

| 133/4/1. | [0] | 139409-0200 | SHIM D11.9&9T0.5 |

| 133/4/1. | [0] | 139409-0300 | SHIM D11.5&9T0.8 |

| 135. | [1] | 159248-2700 | FLAT-HEAD SCREW |

| 137. | [1] | 159237-5300 | CAPSULE |

| 140. | [1] | 159205-2101 | LEVER SHAFT |

| 145. | [1] | 159233-5700 | UNION NUT |

| 149. | [1] | 159237-5400 | CAPSULE |

| 150. | [1] | 159235-5300 | SLOTTED WASHER |

| 155. | [1] | 159204-5120 | STRAP |

| 156. | [1] | 159233-0520 | BLEEDER SCREW |

| 158. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 160. | [1] | 159252-0821 | LEVER GROUP |

| 160/1. | [1] | 159202-2200 | CONTROL LEVER |

| 160/2. | [1] | 016010-0810 | LOCKING WASHER |

| 160/3. | [1] | 159202-2120 | CONTROL LEVER |

| 160/4. | [1] | 016010-0810 | LOCKING WASHER |

| 160/5. | [1] | 159215-2301 | COILED SPRING |

| 160/7. | [1] | 159205-2222 | LEVER SHAFT |

| 168/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 168/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 168/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 168/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 168/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 168/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 168/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 168/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 168/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 168/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 168/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 169. | [1] | 139410-2300 | SHIM |

| 170. | [1] | 159262-8520 | CONTROL LEVER |

| 172. | [1] | 159233-6100 | UNION NUT |

| 173/1. | [1] | 139006-3500 | BLEEDER SCREW M6P1.0L33 |

| 173/1. | [1] | 139006-3700 | BLEEDER SCREW M6P1.0L34 |

| 173/1. | [1] | 139006-3800 | BLEEDER SCREW M6P1.0L35 |

| 173/1. | [1] | 139006-3900 | BLEEDER SCREW M6P1.0L36 |

| 173/1. | [1] | 139006-5300 | BLEEDER SCREW M6P1.0L31 |

| 173/1. | [1] | 139006-5400 | BLEEDER SCREW M6P1.0L32 |

| 173/1. | [1] | 155615-2500 | BLEEDER SCREW M6P1.0L37 |

| 174. | [1] | 154010-7200 | BLEEDER SCREW M8P1.25L62 |

| 174B. | [1] | 154010-8100 | BLEEDER SCREW M8P1.25L65 |

| 175. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 176. | [1] | 159225-8600 | UNION NUT |

| 177. | [1] | 154011-2300 | UNION NUT |

| 178. | [1] | 154011-0100 | HEXAGON NUT |

| 180. | [2] | 159235-6300 | PLAIN WASHER |

| 180. | [2] | 159235-6300 | PLAIN WASHER |

| 181. | [1] | 159260-8420 | CONTROL LEVER |

| 182. | [1] | 016010-0940 | LOCKING WASHER |

| 183. | [1] | 029301-0020 | PLAIN WASHER |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 159238-3100 | GASKET |

| 251. | [2] | 159243-9800 | COILED SPRING |

| 251B. | [1] | 159243-1200 | COILED SPRING |

| 257. | [3] | 154156-0500 | TUBE |

| 300. | [1] | 159282-3600 | CAM PLATE |

| 301. | [1] | 016010-0840 | LOCKING WASHER |

| 303. | [1] | 016010-0540 | LOCKING WASHER |

| 311. | [1] | 159237-0200 | CAPSULE |

| 320. | [1] | 154419-7020 | MANIFOLD-PRESSURE COMP. |

| 320/1. | [1] | 154408-9620 | DIAPHRAGM HOUSING |

| 320/1A. | [1] | 154418-3900 | SPACER BUSHING |

| 320/2. | [3] | 020106-2540 | BLEEDER SCREW M6P1L25 |

| 320/2. | [3] | 020106-2540 | BLEEDER SCREW M6P1L25 |

| 320/3. | [1] | 020118-3040 | BLEEDER SCREW |

| 320/5. | [1] | 159275-1400 | COILED SPRING |

| 320/6/1. | [1] | 159274-0120 | STOP PIN L125 |

| 320/6/1. | [1] | 159274-0220 | STOP PIN L127.50 |

| 320/6/1. | [1] | 159274-0320 | STOP PIN L128.00 |

| 320/6/1. | [1] | 159274-0420 | STOP PIN L127.00 |

| 320/6/1. | [1] | 159274-0520 | STOP PIN L126.00 |

| 320/6/1. | [1] | 159274-0620 | STOP PIN L129.00 |

| 320/6/1. | [1] | 159274-0720 | STOP PIN L128.50 |

| 320/6/1. | [1] | 159274-0820 | STOP PIN L125.50 |

| 320/6/1. | [1] | 159274-0920 | STOP PIN L126.50 |

| 320/6/1. | [1] | 159274-1120 | STOP PIN L119.5 |

| 320/6/1. | [1] | 159274-1220 | STOP PIN L120 |

| 320/6/1. | [1] | 159274-1320 | STOP PIN L120.5 |

| 320/6/1. | [1] | 159274-1420 | STOP PIN L121 |

| 320/6/1. | [1] | 159274-1520 | STOP PIN L121.5 |

| 320/6/1. | [1] | 159274-1620 | STOP PIN L122 |

| 320/6/1. | [1] | 159274-1720 | STOP PIN L122.5 |

| 320/6/1. | [1] | 159274-1820 | STOP PIN L123 |

| 320/6/1. | [1] | 159274-1920 | STOP PIN L123.5 |

| 320/6/1. | [1] | 159274-4220 | STOP PIN L129.5 |

| 320/6/1. | [1] | 159274-4320 | STOP PIN L130 |

| 320/6/1. | [1] | 159274-4420 | STOP PIN L130.5 |

| 320/6/1. | [1] | 159274-4520 | STOP PIN L131 |

| 320/6/1. | [1] | 159274-4620 | STOP PIN L131.5 |

| 320/6/1. | [1] | 159274-4720 | STOP PIN L132 |

| 320/6/1. | [1] | 159274-4820 | STOP PIN L132.5 |

| 320/6/1. | [1] | 159274-4920 | STOP PIN L133 |

| 320/6/1. | [1] | 159274-5020 | STOP PIN L133.5 |

| 320/11. | [1] | 154400-8521 | DIAPHRAGM |

| 320/14. | [1] | 154406-5500 | SLOTTED WASHER |

| 320/15. | [1] | 013030-6010 | UNION NUT |

| 320/16. | [1] | 154402-0100 | COILED SPRING |

| 320/17. | [2] | 154413-2600 | GASKET |

| 320/17. | [2] | 154413-2600 | GASKET |

| 320/18. | [1] | 154404-5000 | COVER |

| 320/19. | [1] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 320/20. | [2] | 139006-7000 | BLEEDER SCREW |

| 320/21. | [2] | 014110-6440 | LOCKING WASHER |

| 320/24. | [3] | 020106-2240 | BLEEDER SCREW |

| 320/25. | [1] | 139006-1300 | BLEEDER SCREW M6P1L76 |

| 320/26. | [1] | 029320-6010 | LOCKING WASHER |

| 320/27. | [1] | 029731-0180 | EYE BOLT |

| 320/28. | [2] | 139510-0200 | GASKET |

| 320/29. | [1] | 154413-2800 | GASKET |

| 320/43. | [1] | 159226-4500 | SPACER RING |

| 320/44. | [1] | 014010-5140 | PLAIN WASHER D12&5.5T0.8 |

| 320/45. | [1] | 139518-0000 | GASKET |

| 320/46. | [1] | 154406-5800 | FLAT-HEAD SCREW |

| 320/47. | [1] | 014110-6440 | LOCKING WASHER |

| 320/54. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 320/55. | [1] | 154404-4800 | FLAT-HEAD SCREW |

| 320/61. | [1] | 154035-1600 | CAP NUT |

| 320/62. | [1] | 154404-4400 | FLAT-HEAD SCREW |

| 320/63. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 320/64. | [2] | 139506-0300 | GASKET |

| 331. | [1] | 159226-4800 | SPACER BUSHING |

| 332. | [1] | 020106-2840 | BLEEDER SCREW |

| 335. | [1] | 159228-4120 | BRACKET |

| 500. | [1] | 154600-9220 | LOAD SENSOR ASSY |

| 501. | [1] | 154604-7220 | STRAP |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105931-6564

1157704950 ISUZU

GOVERNOR

K 14JK MECHANICAL GOVERNOR GOV RLD GOV

K 14JK MECHANICAL GOVERNOR GOV RLD GOV

Information:

Engine and Attachment Lifting

When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt is less as the angle between the supporting members and the object becomes less than 90 degrees. Eyebolts and brackets should never be bent and should only be loaded in tension.

Use a hoist to remove heavy components. Lift the engine by using an adjustable lifting beam. All supporting members (chains and cables) should be parallel to each other, and as near perpendicular as possible to the top of the object being lifted.To remove the engine ONLY, use the lifting eyes equipped with the engine. Lifting eyes are designed for the arrangement as sold and the end user is responsible for providing lifting devices. Alterations to lifting eyes and/or arrangement weight make the lifting eyes and devices obsolete. If you make alterations to the engine package as sold, you are responsible for providing adequate lifting devices.Engine Storage

These instructions and recommendations will safeguard the possibility of engine damage if the engines are in storage for one year or less.If the engine will not be or has not been started for several weeks, the lubricating oil will drain from the cylinder walls and piston rings.If an engine remains out of service and its use is not immediately planned, special precautions should be taken. Rust can form on the cylinder liner surface, which will increase engine wear and may result in shorter engine life. To prevent this problem from becoming excessive, be sure all lubrication recommendations mentioned in the Maintenance Schedule are completed.After one year, a complete protection procedure must be followed if the engine is kept in storage longer.If it will be impossible to start the engine periodically, consult your Caterpillar dealer for instructions to prepare your engine for longer storage periods.If an engine remains out of service and its use is not immediately planned, special precautions should be taken. Refer to Storage Procedures For Caterpillar Products, SEHS9031 for more detailed information on engine storage. To prevent excessive engine wear:Be sure all lubrication recommendations mentioned in the Maintenance Schedule intervals chart are completed.If freezing temperatures are expected, check the cooling system for adequate protection against freezing. A 50/50 solution of Caterpillar permanent-type antifreeze and approved water will give protection below -29°C (-20°F). The engine can be stored between temperatures -50°C (-58°F) and 85°C (185°F).

When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt is less as the angle between the supporting members and the object becomes less than 90 degrees. Eyebolts and brackets should never be bent and should only be loaded in tension.

Use a hoist to remove heavy components. Lift the engine by using an adjustable lifting beam. All supporting members (chains and cables) should be parallel to each other, and as near perpendicular as possible to the top of the object being lifted.To remove the engine ONLY, use the lifting eyes equipped with the engine. Lifting eyes are designed for the arrangement as sold and the end user is responsible for providing lifting devices. Alterations to lifting eyes and/or arrangement weight make the lifting eyes and devices obsolete. If you make alterations to the engine package as sold, you are responsible for providing adequate lifting devices.Engine Storage

These instructions and recommendations will safeguard the possibility of engine damage if the engines are in storage for one year or less.If the engine will not be or has not been started for several weeks, the lubricating oil will drain from the cylinder walls and piston rings.If an engine remains out of service and its use is not immediately planned, special precautions should be taken. Rust can form on the cylinder liner surface, which will increase engine wear and may result in shorter engine life. To prevent this problem from becoming excessive, be sure all lubrication recommendations mentioned in the Maintenance Schedule are completed.After one year, a complete protection procedure must be followed if the engine is kept in storage longer.If it will be impossible to start the engine periodically, consult your Caterpillar dealer for instructions to prepare your engine for longer storage periods.If an engine remains out of service and its use is not immediately planned, special precautions should be taken. Refer to Storage Procedures For Caterpillar Products, SEHS9031 for more detailed information on engine storage. To prevent excessive engine wear:Be sure all lubrication recommendations mentioned in the Maintenance Schedule intervals chart are completed.If freezing temperatures are expected, check the cooling system for adequate protection against freezing. A 50/50 solution of Caterpillar permanent-type antifreeze and approved water will give protection below -29°C (-20°F). The engine can be stored between temperatures -50°C (-58°F) and 85°C (185°F).