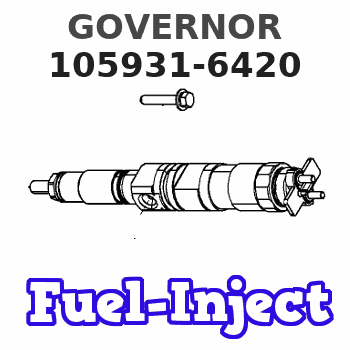

Information governor

BOSCH

9 420 613 593

9420613593

ZEXEL

105931-6420

1059316420

MITSUBISHI

ME727015

me727015

Rating:

Scheme ###:

| 1. | [1] | 159200-4220 | GOVERNOR HOUSING |

| 2. | [1] | 154007-0200 | ADAPTOR |

| 3. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 4. | [1] | 159232-2620 | PLATE |

| 5. | [5] | 029010-6810 | BLEEDER SCREW |

| 5B. | [1] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 7. | [1] | 016530-1010 | O-RING |

| 8. | [1] | 159205-2321 | LEVER SHAFT |

| 9. | [1] | 159202-5101 | CONTROL LEVER |

| 10. | [1] | 016010-0810 | LOCKING WASHER |

| 11/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 11/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 11/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 11/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 11/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 11/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 11/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 11/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 11/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 12. | [1] | 159215-0000 | COILED SPRING |

| 13. | [1] | 159242-6601 | CONTROL LEVER |

| 15. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 16. | [1] | 159237-5500 | CAPSULE |

| 17. | [1] | 159202-5220 | CONTROL LEVER |

| 18. | [1] | 159215-1600 | COILED SPRING |

| 20. | [1] | 159242-0220 | CONTROL LEVER |

| 21. | [1] | 159242-0600 | BUSHING |

| 22. | [1] | 016530-1010 | O-RING |

| 23/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 23/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 23/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 23/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 23/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 23/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 23/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 23/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 23/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 24. | [1] | 159215-2000 | COILED SPRING |

| 25. | [1] | 159235-5800 | CAP |

| 26. | [1] | 159249-6920 | CONTROL LEVER |

| 27. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 35. | [1] | 159251-8720 | GOVERNOR COVER |

| 35/1. | [1] | 159201-7020 | GOVERNOR COVER |

| 35/2. | [1] | 159205-0400 | LEVER SHAFT |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/4. | [1] | 159253-2220 | TENSIONING LEVER |

| 35/4/1. | [1] | 159203-1720 | TENSIONING LEVER |

| 35/4/2. | [1] | 159204-5021 | RACK |

| 35/4/3. | [1] | 159233-0300 | UNION NUT |

| 35/4/4. | [1] | 159234-0300 | FLAT-HEAD SCREW |

| 35/4/5. | [1] | 159216-0000 | COILED SPRING |

| 35/4/6. | [1] | 159216-0100 | COILED SPRING |

| 35/5. | [1] | 159203-6120 | GUIDE LEVER |

| 35/7. | [1] | 159215-1701 | COILED SPRING |

| 35/8. | [1] | 159231-1300 | BEARING PIN |

| 35/9. | [2] | 016010-0610 | LOCKING WASHER |

| 35/10. | [1] | 159238-2900 | BUSHING |

| 51. | [6] | 020106-3840 | BLEEDER SCREW |

| 51B. | [1] | 020106-4040 | BLEEDER SCREW |

| 65. | [1] | 154050-1720 | STOPPING DEVICE |

| 100. | [1] | 154100-9520 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 110. | [1] | 154123-2320 | SLIDING PIECE |

| 111/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 111/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 111/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 111/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 111/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 111/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 111/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 111/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 111/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 112. | [1] | 159236-0200 | TERMINAL STUD |

| 130. | [1] | 159210-5400 | GOVERNOR SPRING |

| 131. | [1] | 159211-2400 | GOVERNOR SPRING |

| 132. | [1] | 159214-0100 | COILED SPRING |

| 133. | [1] | 159212-4720 | SPRING PACK |

| 133/1. | [1] | 159234-5602 | GUIDE SLEEVE |

| 133/2. | [1] | 159212-4700 | COILED SPRING |

| 133/3. | [1] | 159212-4600 | COILED SPRING |

| 133/4/1. | [0] | 029310-9240 | SHIM D11.9&9T0.1 |

| 133/4/1. | [0] | 029310-9250 | SHIM D11.9&9T0.2 |

| 133/4/1. | [0] | 029310-9260 | SHIM D11.9&9T0.25 |

| 133/4/1. | [0] | 029310-9270 | SHIM D11.9&9T1.0 |

| 133/4/1. | [0] | 139409-0100 | SHIM D11.9&9T0.3 |

| 133/4/1. | [0] | 139409-0200 | SHIM D11.9&9T0.5 |

| 133/4/1. | [0] | 139409-0300 | SHIM D11.5&9T0.8 |

| 135. | [1] | 159248-2700 | FLAT-HEAD SCREW |

| 137. | [1] | 159237-5300 | CAPSULE |

| 140. | [1] | 159205-2101 | LEVER SHAFT |

| 145. | [1] | 159233-5700 | UNION NUT |

| 149. | [1] | 159237-5400 | CAPSULE |

| 150. | [1] | 159235-5300 | SLOTTED WASHER |

| 155. | [1] | 159204-7720 | STRAP |

| 156. | [1] | 159233-0520 | BLEEDER SCREW |

| 158. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 160. | [1] | 159252-0821 | LEVER GROUP |

| 160/1. | [1] | 159202-2200 | CONTROL LEVER |

| 160/2. | [1] | 016010-0810 | LOCKING WASHER |

| 160/3. | [1] | 159202-2120 | CONTROL LEVER |

| 160/4. | [1] | 016010-0810 | LOCKING WASHER |

| 160/5. | [1] | 159215-2301 | COILED SPRING |

| 160/7. | [1] | 159205-2222 | LEVER SHAFT |

| 168/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 168/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 168/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 168/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 168/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 168/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 168/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 168/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 168/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 168/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 168/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 169. | [1] | 139410-2300 | SHIM |

| 170. | [1] | 159262-5320 | CONTROL LEVER |

| 172. | [1] | 159231-4400 | UNION NUT |

| 173/1. | [1] | 139006-3500 | BLEEDER SCREW M6P1.0L33 |

| 173/1. | [1] | 139006-3700 | BLEEDER SCREW M6P1.0L34 |

| 173/1. | [1] | 139006-3800 | BLEEDER SCREW M6P1.0L35 |

| 173/1. | [1] | 139006-3900 | BLEEDER SCREW M6P1.0L36 |

| 173/1. | [1] | 139006-5300 | BLEEDER SCREW M6P1.0L31 |

| 173/1. | [1] | 139006-5400 | BLEEDER SCREW M6P1.0L32 |

| 173/1. | [1] | 155615-2500 | BLEEDER SCREW M6P1.0L37 |

| 174. | [1] | 154010-7200 | BLEEDER SCREW M8P1.25L62 |

| 175. | [1] | 154010-2900 | BLEEDER SCREW |

| 176. | [1] | 159225-8600 | UNION NUT |

| 177. | [1] | 154011-2300 | UNION NUT |

| 178. | [1] | 154011-0100 | HEXAGON NUT |

| 180. | [2] | 154371-0000 | PLAIN WASHER |

| 180. | [2] | 154371-0000 | PLAIN WASHER |

| 181. | [1] | 159262-5520 | CONTROL LEVER |

| 182. | [1] | 029300-8010 | PLAIN WASHER D15&8T1.00 |

| 183. | [1] | 016010-0740 | LOCKING WASHER |

| 184. | [1] | 159215-4600 | COILED SPRING |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 159238-3100 | GASKET |

| 250. | [1] | 159229-2520 | BRACKET |

| 251. | [2] | 159243-9900 | COILED SPRING |

| 252. | [1] | 159248-0200 | BLEEDER SCREW |

| 253. | [1] | 139010-1000 | STUD |

| 257. | [2] | 154156-0500 | TUBE |

| 300. | [1] | 159281-1400 | CAM PLATE |

| 301. | [1] | 016010-0840 | LOCKING WASHER |

| 303. | [1] | 016010-0540 | LOCKING WASHER |

| 311. | [1] | 159237-0200 | CAPSULE |

| 320. | [1] | 154419-4020 | MANIFOLD-PRESSURE COMP. |

| 320/1. | [1] | 154408-9620 | DIAPHRAGM HOUSING |

| 320/1A. | [1] | 154418-3900 | SPACER BUSHING |

| 320/2. | [1] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 320/2B. | [2] | 020106-2540 | BLEEDER SCREW M6P1L25 |

| 320/3. | [1] | 020118-3040 | BLEEDER SCREW |

| 320/5. | [1] | 159275-1400 | COILED SPRING |

| 320/6/1. | [1] | 159274-0120 | STOP PIN L125 |

| 320/6/1. | [1] | 159274-0220 | STOP PIN L127.50 |

| 320/6/1. | [1] | 159274-0320 | STOP PIN L128.00 |

| 320/6/1. | [1] | 159274-0420 | STOP PIN L127.00 |

| 320/6/1. | [1] | 159274-0520 | STOP PIN L126.00 |

| 320/6/1. | [1] | 159274-0620 | STOP PIN L129.00 |

| 320/6/1. | [1] | 159274-0720 | STOP PIN L128.50 |

| 320/6/1. | [1] | 159274-0820 | STOP PIN L125.50 |

| 320/6/1. | [1] | 159274-0920 | STOP PIN L126.50 |

| 320/6/1. | [1] | 159274-1120 | STOP PIN L119.5 |

| 320/6/1. | [1] | 159274-1220 | STOP PIN L120 |

| 320/6/1. | [1] | 159274-1320 | STOP PIN L120.5 |

| 320/6/1. | [1] | 159274-1420 | STOP PIN L121 |

| 320/6/1. | [1] | 159274-1520 | STOP PIN L121.5 |

| 320/6/1. | [1] | 159274-1620 | STOP PIN L122 |

| 320/6/1. | [1] | 159274-1720 | STOP PIN L122.5 |

| 320/6/1. | [1] | 159274-1820 | STOP PIN L123 |

| 320/6/1. | [1] | 159274-1920 | STOP PIN L123.5 |

| 320/6/1. | [1] | 159274-4220 | STOP PIN L129.5 |

| 320/6/1. | [1] | 159274-4320 | STOP PIN L130 |

| 320/6/1. | [1] | 159274-4420 | STOP PIN L130.5 |

| 320/6/1. | [1] | 159274-4520 | STOP PIN L131 |

| 320/6/1. | [1] | 159274-4620 | STOP PIN L131.5 |

| 320/6/1. | [1] | 159274-4720 | STOP PIN L132 |

| 320/6/1. | [1] | 159274-4820 | STOP PIN L132.5 |

| 320/6/1. | [1] | 159274-4920 | STOP PIN L133 |

| 320/6/1. | [1] | 159274-5020 | STOP PIN L133.5 |

| 320/11. | [1] | 154400-8521 | DIAPHRAGM |

| 320/14. | [1] | 154406-5500 | SLOTTED WASHER |

| 320/15. | [1] | 013030-6010 | UNION NUT |

| 320/16. | [1] | 154402-0100 | COILED SPRING |

| 320/17. | [2] | 154413-2600 | GASKET |

| 320/18. | [1] | 154404-5100 | COVER |

| 320/19. | [1] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 320/20. | [1] | 139006-7000 | BLEEDER SCREW |

| 320/20B. | [1] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 320/21. | [1] | 014110-6440 | LOCKING WASHER |

| 320/24. | [3] | 020106-2240 | BLEEDER SCREW |

| 320/25. | [1] | 139006-1300 | BLEEDER SCREW M6P1L76 |

| 320/26. | [1] | 029320-6010 | LOCKING WASHER |

| 320/27. | [1] | 154412-7500 | EYE BOLT |

| 320/28. | [3] | 026510-1340 | GASKET D13.4&10.2T1 |

| 320/29. | [1] | 154413-2800 | GASKET |

| 320/41. | [1] | 154412-7400 | BUSHING |

| 320/43. | [1] | 159226-4500 | SPACER RING |

| 320/44. | [1] | 014010-5140 | PLAIN WASHER D12&5.5T0.8 |

| 320/45. | [1] | 029331-8040 | GASKET |

| 320/46. | [1] | 154406-5800 | FLAT-HEAD SCREW |

| 320/47. | [1] | 014110-6440 | LOCKING WASHER |

| 320/54. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 320/55. | [1] | 154404-4800 | FLAT-HEAD SCREW |

| 320/61. | [1] | 154035-1600 | CAP NUT |

| 320/62. | [1] | 154404-4400 | FLAT-HEAD SCREW |

| 320/63. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 320/64. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 340. | [1] | 159245-8300 | PLATE |

| 341. | [2] | 020104-1040 | BLEEDER SCREW |

| 350. | [1] | 159227-7900 | BRACKET |

| 353. | [1] | 159225-5120 | PLATE |

| 354. | [1] | 020106-0840 | BLEEDER SCREW |

Include in #1:

101606-6720

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

105931-6420

9 420 613 593

ME727015 MITSUBISHI

GOVERNOR

* K

* K

Information:

Antifreeze

Caterpillar recommends that the coolant mix contain a minimum of 30% Caterpillar Antifreeze, or equivalent and acceptable water to maintain an adequate water pump cavitation temperature for efficient water pump performance.Premix coolant solution to provide protection to the lowest expected outside (ambient) temperature. Pure undiluted antifreeze will freeze at -10°F (-23°C).Only use a greater concentration (above 30%) of Caterpillar Antifreeze as needed for anticipated outside (ambient) temperatures. Do not exceed a coolant mixture of 60% antifreeze to water since a concentration above 60% antifreeze will reduce the engine's freeze protection and increase the possibility of deposit formation in the cooling system.

Use Caterpillar Antifreeze or ASTM D4985-89 (GM Specification 6038-M) Antifreeze. However, supplemental coolant conditioner must be added to these coolants. See topic "Supplemental CoolantAdditive (Conditioner)" in this manual for further information.Caterpillar Antifreeze is available through your Caterpillar dealer in quantities that follow. Most commercial antifreezes are formulated for gasoline engine applications and will, therefore, have high silicate content. Caterpillar Antifreeze is formulated with a low silicate content and the proper coolant additives for heavy duty diesel engines. Caterpillar does not recommend use of high silicate antifreeze in the 3176 engine.ASTM D4985-89 (GM Specification 6038-M) is a low silicate antifreeze, but supplemental coolant additive must be added.The major advantages of Caterpillar Antifreeze are:* Significantly reduces water pump seal leakage problems caused by excessive concentration of chemical additives.* There is no need to add supplemental coolant additive (conditioner) on initial fill, which must be done with current commercially available antifreezes.* High silicate antifreezes used with a supplemental coolant additive can cause a build-up of solids over a period of time which can cause plugging, loss of heat transfer, and water pump seal damage.Make proper antifreeze additions.

Adding pure antifreezes as a makeup solution for cooling system top-off is an unacceptable practice. It increase the concentration of antifreeze in the cooling system which increases the concentration of dissolved solids and undissolved chemical inhibitors in the cooling system. Add antifreeze mixed with acceptable water to the same freeze protection as your cooling system. Pure, undiluted antifreeze will freeze at -10°F (-23°C).Use the chart below to assist in determining the concentration of Caterpillar Antifreeze to use.

5P0957 Coolant Tester (°F) or 5P3514 Coolant Tester (°C)Both are available at your Caterpillar dealer.Check the coolant solution frequently in cold weather for glycol concentration with the 5P0957 or 5P3514 Coolant Tester to ensure adequate protection. Both testers are identical except temperature scale. They give immediate, accurate readings and can be used for antifreeze/coolants that contain ethylene or propylene glycol.If propylene glycol based antifreeze is used, DO NOT allow concentration greater than a 50/50 antifreeze to water mixture. The measurement of freeze protection must be made with a refractive-type tester (Cat 5P0957 or 5P3514) rather than a hydrometer-type, which can be used to test ethylene glycol based antifreeze.Supplemental Coolant Additive (Conditioner)

Supplemental coolant additive (conditioner) is necessary to prevent rust, scale, pitting and/or corrosion of engine parts that coolant comes in contact with. Most antifreeze solutions DO NOT contain sufficient

Caterpillar recommends that the coolant mix contain a minimum of 30% Caterpillar Antifreeze, or equivalent and acceptable water to maintain an adequate water pump cavitation temperature for efficient water pump performance.Premix coolant solution to provide protection to the lowest expected outside (ambient) temperature. Pure undiluted antifreeze will freeze at -10°F (-23°C).Only use a greater concentration (above 30%) of Caterpillar Antifreeze as needed for anticipated outside (ambient) temperatures. Do not exceed a coolant mixture of 60% antifreeze to water since a concentration above 60% antifreeze will reduce the engine's freeze protection and increase the possibility of deposit formation in the cooling system.

Use Caterpillar Antifreeze or ASTM D4985-89 (GM Specification 6038-M) Antifreeze. However, supplemental coolant conditioner must be added to these coolants. See topic "Supplemental CoolantAdditive (Conditioner)" in this manual for further information.Caterpillar Antifreeze is available through your Caterpillar dealer in quantities that follow. Most commercial antifreezes are formulated for gasoline engine applications and will, therefore, have high silicate content. Caterpillar Antifreeze is formulated with a low silicate content and the proper coolant additives for heavy duty diesel engines. Caterpillar does not recommend use of high silicate antifreeze in the 3176 engine.ASTM D4985-89 (GM Specification 6038-M) is a low silicate antifreeze, but supplemental coolant additive must be added.The major advantages of Caterpillar Antifreeze are:* Significantly reduces water pump seal leakage problems caused by excessive concentration of chemical additives.* There is no need to add supplemental coolant additive (conditioner) on initial fill, which must be done with current commercially available antifreezes.* High silicate antifreezes used with a supplemental coolant additive can cause a build-up of solids over a period of time which can cause plugging, loss of heat transfer, and water pump seal damage.Make proper antifreeze additions.

Adding pure antifreezes as a makeup solution for cooling system top-off is an unacceptable practice. It increase the concentration of antifreeze in the cooling system which increases the concentration of dissolved solids and undissolved chemical inhibitors in the cooling system. Add antifreeze mixed with acceptable water to the same freeze protection as your cooling system. Pure, undiluted antifreeze will freeze at -10°F (-23°C).Use the chart below to assist in determining the concentration of Caterpillar Antifreeze to use.

5P0957 Coolant Tester (°F) or 5P3514 Coolant Tester (°C)Both are available at your Caterpillar dealer.Check the coolant solution frequently in cold weather for glycol concentration with the 5P0957 or 5P3514 Coolant Tester to ensure adequate protection. Both testers are identical except temperature scale. They give immediate, accurate readings and can be used for antifreeze/coolants that contain ethylene or propylene glycol.If propylene glycol based antifreeze is used, DO NOT allow concentration greater than a 50/50 antifreeze to water mixture. The measurement of freeze protection must be made with a refractive-type tester (Cat 5P0957 or 5P3514) rather than a hydrometer-type, which can be used to test ethylene glycol based antifreeze.Supplemental Coolant Additive (Conditioner)

Supplemental coolant additive (conditioner) is necessary to prevent rust, scale, pitting and/or corrosion of engine parts that coolant comes in contact with. Most antifreeze solutions DO NOT contain sufficient

Have questions with 105931-6420?

Group cross 105931-6420 ZEXEL

Nissan-Diesel

Mitsubishi

105931-6420

9 420 613 593

ME727015

GOVERNOR