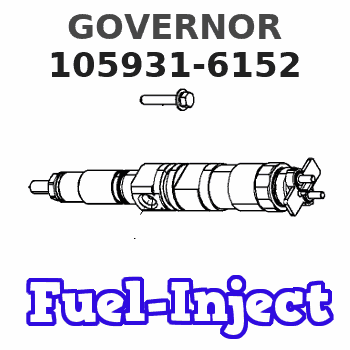

Information governor

BOSCH

F 019 Z5E 760

f019z5e760

ZEXEL

105931-6152

1059316152

ISUZU

8943760822

8943760822

Rating:

Scheme ###:

| 1. | [1] | 159200-6600 | GOVERNOR HOUSING |

| 2. | [1] | 154007-0200 | ADAPTOR |

| 3. | [1] | 020018-1840 | BLEEDER SCREW |

| 4. | [1] | 159232-2620 | PLATE |

| 5. | [5] | 029010-6810 | BLEEDER SCREW |

| 5B. | [1] | 020106-1640 | BLEEDER SCREW |

| 7. | [1] | 016530-1010 | O-RING |

| 8. | [1] | 159205-2321 | LEVER SHAFT |

| 9. | [1] | 159202-5101 | CONTROL LEVER |

| 10. | [1] | 016010-0810 | LOCKING WASHER |

| 11/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 11/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 11/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 11/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 11/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 11/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 11/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 11/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 11/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 12. | [1] | 159215-0000 | COILED SPRING |

| 13. | [1] | 159242-6601 | CONTROL LEVER |

| 15. | [1] | 013020-8040 | UNION NUT |

| 16. | [1] | 159237-5500 | CAPSULE |

| 17. | [1] | 159202-5320 | CONTROL LEVER |

| 18. | [1] | 159215-0300 | COILED SPRING |

| 35. | [1] | 159251-8620 | GOVERNOR COVER |

| 35/1. | [1] | 159201-3422 | GOVERNOR COVER |

| 35/2. | [1] | 159205-0400 | LEVER SHAFT |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/4. | [1] | 159253-2220 | TENSIONING LEVER |

| 35/4/1. | [1] | 159203-1720 | TENSIONING LEVER |

| 35/4/2. | [1] | 159204-5021 | RACK |

| 35/4/3. | [1] | 159233-0300 | UNION NUT |

| 35/4/4. | [1] | 159234-0300 | FLAT-HEAD SCREW |

| 35/4/5. | [1] | 159216-0000 | COILED SPRING |

| 35/4/6. | [1] | 159216-0100 | COILED SPRING |

| 35/5. | [1] | 159203-6120 | GUIDE LEVER |

| 35/7. | [1] | 159215-1701 | COILED SPRING |

| 35/8. | [1] | 159231-1300 | BEARING PIN |

| 35/9. | [2] | 016010-0610 | LOCKING WASHER |

| 35/10. | [1] | 159238-2900 | BUSHING |

| 51. | [7] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 155404-5700 | CAP |

| 100. | [1] | 154100-9520 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY 16 MM |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 110. | [1] | 154123-2320 | SLIDING PIECE |

| 111/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 111/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 111/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 111/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 111/1. | [0] | 139410-0000 | SHIM D14&10.1T0.5 |

| 111/1. | [0] | 139410-0100 | SHIM D14&10.1T1.5 |

| 111/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 111/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 111/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 112. | [1] | 159236-0200 | TERMINAL STUD |

| 130. | [1] | 159210-1000 | GOVERNOR SPRING |

| 131. | [1] | 159211-4300 | GOVERNOR SPRING |

| 132. | [1] | 159214-0000 | COILED SPRING |

| 133. | [1] | 159212-7320 | SPRING PACK |

| 133/1. | [1] | 159234-5602 | GUIDE SLEEVE |

| 133/2. | [1] | 159212-5000 | COILED SPRING |

| 133/3. | [1] | 159212-4600 | COILED SPRING |

| 133/4/1. | [0] | 029310-9240 | SHIM D11.9&9T0.1 |

| 133/4/1. | [0] | 029310-9250 | SHIM D11.9&9T0.2 |

| 133/4/1. | [0] | 029310-9260 | SHIM D11.9&9T0.25 |

| 133/4/1. | [0] | 029310-9270 | SHIM D11.9&9T1.0 |

| 133/4/1. | [0] | 139409-0100 | SHIM D11.9&9T0.3 |

| 133/4/1. | [0] | 139409-0200 | SHIM D11.9&9T0.5 |

| 133/4/1. | [0] | 139409-0300 | SHIM D11.5&9T0.8 |

| 135. | [1] | 159248-2700 | FLAT-HEAD SCREW |

| 137. | [1] | 159237-5300 | CAPSULE |

| 140. | [1] | 159205-2101 | LEVER SHAFT |

| 145. | [1] | 159233-5700 | UNION NUT |

| 149. | [1] | 159237-5400 | CAPSULE |

| 150. | [1] | 159235-5300 | SLOTTED WASHER |

| 155. | [1] | 159204-7720 | STRAP |

| 156. | [1] | 159233-0520 | BLEEDER SCREW |

| 158. | [1] | 013020-5240 | UNION NUT |

| 160. | [1] | 159252-0821 | LEVER GROUP |

| 160/1. | [1] | 159202-2200 | CONTROL LEVER |

| 160/2. | [1] | 016010-0810 | LOCKING WASHER |

| 160/3. | [1] | 159202-2120 | CONTROL LEVER |

| 160/4. | [1] | 016010-0810 | LOCKING WASHER |

| 160/5. | [1] | 159215-2301 | COILED SPRING |

| 160/7. | [1] | 159205-2222 | LEVER SHAFT |

| 168/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 168/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 168/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 168/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 168/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 168/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 168/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 168/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 168/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 168/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 168/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 169. | [1] | 139410-2300 | SHIM |

| 170. | [1] | 159261-9621 | CONTROL LEVER |

| 172. | [1] | 013020-8040 | UNION NUT |

| 173/1. | [1] | 139006-3500 | BLEEDER SCREW M6P1.0L33 |

| 173/1. | [1] | 139006-3700 | BLEEDER SCREW M6P1.0L34 |

| 173/1. | [1] | 139006-3800 | BLEEDER SCREW M6P1.0L35 |

| 173/1. | [1] | 139006-3900 | BLEEDER SCREW M6P1.0L36 |

| 173/1. | [1] | 139006-5300 | BLEEDER SCREW M6P1.0L31 |

| 173/1. | [1] | 139006-5400 | BLEEDER SCREW M6P1.0L32 |

| 173/1. | [1] | 155615-2500 | BLEEDER SCREW M6P1.0L37 |

| 174. | [1] | 154010-8100 | BLEEDER SCREW |

| 175. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 176. | [1] | 159225-8600 | UNION NUT |

| 177. | [1] | 154011-2300 | UNION NUT |

| 178. | [1] | 154011-0100 | HEXAGON NUT |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 159238-3100 | GASKET |

| 250. | [1] | 159225-1820 | BRACKET |

| 251. | [2] | 159243-1900 | COILED SPRING |

| 252. | [1] | 159248-0200 | BLEEDER SCREW |

| 253. | [1] | 159248-0401 | BLEEDER SCREW |

| 257. | [2] | 154156-0500 | TUBE |

| 300. | [1] | 159280-6500 | CAM PLATE |

| 301. | [1] | 016010-0840 | LOCKING WASHER |

| 303. | [1] | 016010-0540 | LOCKING WASHER |

| 311. | [1] | 159237-0200 | CAPSULE |

| 400. | [1] | 159228-7600 | ACTUATOR |

| 401. | [1] | 159228-8700 | BRACKET |

| 402. | [2] | 020146-1240 | BLEEDER SCREW |

| 403. | [1] | 020106-1040 | BLEEDER SCREW M6P1.0L12 |

| 404. | [2] | 020104-1040 | BLEEDER SCREW |

| 405. | [1] | 159228-8800 | PLATE |

| 406. | [1] | 020146-1240 | BLEEDER SCREW |

| 835S. | [1] | 154062-1900 | CAP |

| 836S. | [1] | 154062-1700 | CAP |

Include in #1:

101401-0921

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

USE FUEL CONSUMPTION, SERVICE HOURS OR TIME INTERVAL, WHICHEVER OCCURS FIRST.Daily

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Marine Gear - Check oil level Air Starting Motor (If Equipped) - Check motor oiler level Air Cleaner Indicator - Check Clutch Shift Collar (If Equipped) - Lubricate Raw Water Pump - Check strainer and primeEvery 1900 L (500 gal) of Fuel or 50 Hours*

Zinc Rods - Inspect/Replace Marine Gear Oil and Filter - Change on new or rebuilt marine gears at first 50 hours ONLY, then at Every 2000 Hours thereafter) Air Tank - Drain water/sedimentEvery 4750 L (1250 gal) of Fuel or 125 Hours*

Clutch Shift Collar and Bearing and Shift Lever - 1 Lubricate/Check/AdjustEvery 9500 L (2500 gal) of Fuel or 250 Hours*

Scheduled Oil Sampling (S O S)** - Obtain Engine Oil and Filters** - Replace Fuel System - Drain water & sediment from tank; Replace final filter/Clean primary filter Cooling System - Test for coolant additive concentration; Add liquid coolant additive or replace coolant additive maintenance element (if equipped) Crankcase Breather - Clean Batteries - Clean/Inspect and check electrolyte level Belts, Hoses and Clamps - Inspect/Check Engine Air Cleaners - Clean Valve Lash** (At First Oil Change Only) - Check/Adjust**The oil change interval is based on fuel consumption. Use fuel consumption as the best indicator of oil change interval. The sump capacity also determines oil change interval. Standard sump at 250 Hours, Deep Sump at 500 Hours. Confirm the interval with Scheduled Oil Sampling (S O S) or contact your Caterpillar dealer.Every 38 000 L (10,000 gal) of Fuel or 1000 Hours*

Marine Gear - Replace oil and filter, Clean strainer/breather, Lubricate output shaft seal Governor - Inspect/Lubricate linkage; Check/Adjust fuel ratio control and low idle - Engine Protective Devices - Inspect/CheckEvery 114 000 L (30,000 gal) of Fuel or 3000 Hours*

Engine Valve Lash - Check/Adjust, Inspect valve rotators Cooling System - Clean/Flush/Change coolant and replace thermostat Engine Mounts and Crankshaft Vibration Damper - Inspect/Check PAR Analysis - ObtainEvery 190 000 L (50,000 gal) of Fuel or 5000 Hours*

Fuel Injection Nozzles - Test/Exchange Turbocharger, Jacket Water Pump and Raw Water Pump - Inspect/Rebuild or Exchange Alternator, Air Compressor and Starting Motors - Inspect/Rebuild or Exchange if necessary Rod Bearings1 - Inspect/Replace1Replace if fuel consumption exceeds 45.5 liter (12 U.S. gallon) per hour.OVERHAUL Every 380 000 L (100,000 gal) of Fuel or 10,000 Hours*

Cylinder Head, Connecting Rods, Pistons, Cylinder Liners, Turbocharger, Oil Pump, Spacer Plate, Fuel Ratio Control, Cam Followers, Fuel Transfer Pump and Timing Advance - Inspect/Rebuild or Exchange Piston Rings, Main Bearings, Rod Bearings, Valve Rotators and Crankshaft Seals - Replace Fuel Injection Nozzles - Test Fuel Injection Pump - Test Crankshaft, Camshaft, Cam Bearings, Damper, Governor, Fuel Pump Camshaft and Fuel Rack - Inspect Oil Cooler - Clean/Test Aftercooler Core - Clean/Test Coolant Analysis - Obtain*First Perform Previous Service Hour Items

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Marine Gear - Check oil level Air Starting Motor (If Equipped) - Check motor oiler level Air Cleaner Indicator - Check Clutch Shift Collar (If Equipped) - Lubricate Raw Water Pump - Check strainer and primeEvery 1900 L (500 gal) of Fuel or 50 Hours*

Zinc Rods - Inspect/Replace Marine Gear Oil and Filter - Change on new or rebuilt marine gears at first 50 hours ONLY, then at Every 2000 Hours thereafter) Air Tank - Drain water/sedimentEvery 4750 L (1250 gal) of Fuel or 125 Hours*

Clutch Shift Collar and Bearing and Shift Lever - 1 Lubricate/Check/AdjustEvery 9500 L (2500 gal) of Fuel or 250 Hours*

Scheduled Oil Sampling (S O S)** - Obtain Engine Oil and Filters** - Replace Fuel System - Drain water & sediment from tank; Replace final filter/Clean primary filter Cooling System - Test for coolant additive concentration; Add liquid coolant additive or replace coolant additive maintenance element (if equipped) Crankcase Breather - Clean Batteries - Clean/Inspect and check electrolyte level Belts, Hoses and Clamps - Inspect/Check Engine Air Cleaners - Clean Valve Lash** (At First Oil Change Only) - Check/Adjust**The oil change interval is based on fuel consumption. Use fuel consumption as the best indicator of oil change interval. The sump capacity also determines oil change interval. Standard sump at 250 Hours, Deep Sump at 500 Hours. Confirm the interval with Scheduled Oil Sampling (S O S) or contact your Caterpillar dealer.Every 38 000 L (10,000 gal) of Fuel or 1000 Hours*

Marine Gear - Replace oil and filter, Clean strainer/breather, Lubricate output shaft seal Governor - Inspect/Lubricate linkage; Check/Adjust fuel ratio control and low idle - Engine Protective Devices - Inspect/CheckEvery 114 000 L (30,000 gal) of Fuel or 3000 Hours*

Engine Valve Lash - Check/Adjust, Inspect valve rotators Cooling System - Clean/Flush/Change coolant and replace thermostat Engine Mounts and Crankshaft Vibration Damper - Inspect/Check PAR Analysis - ObtainEvery 190 000 L (50,000 gal) of Fuel or 5000 Hours*

Fuel Injection Nozzles - Test/Exchange Turbocharger, Jacket Water Pump and Raw Water Pump - Inspect/Rebuild or Exchange Alternator, Air Compressor and Starting Motors - Inspect/Rebuild or Exchange if necessary Rod Bearings1 - Inspect/Replace1Replace if fuel consumption exceeds 45.5 liter (12 U.S. gallon) per hour.OVERHAUL Every 380 000 L (100,000 gal) of Fuel or 10,000 Hours*

Cylinder Head, Connecting Rods, Pistons, Cylinder Liners, Turbocharger, Oil Pump, Spacer Plate, Fuel Ratio Control, Cam Followers, Fuel Transfer Pump and Timing Advance - Inspect/Rebuild or Exchange Piston Rings, Main Bearings, Rod Bearings, Valve Rotators and Crankshaft Seals - Replace Fuel Injection Nozzles - Test Fuel Injection Pump - Test Crankshaft, Camshaft, Cam Bearings, Damper, Governor, Fuel Pump Camshaft and Fuel Rack - Inspect Oil Cooler - Clean/Test Aftercooler Core - Clean/Test Coolant Analysis - Obtain*First Perform Previous Service Hour Items