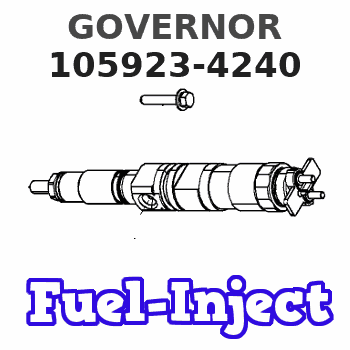

Information governor

BOSCH

9 420 613 852

9420613852

ZEXEL

105923-4240

1059234240

MITSUBISHI

ME748151

me748151

Rating:

Scheme ###:

| 1. | [1] | 159360-0720 | GOVERNOR HOUSING |

| 4. | [1] | 159362-5520 | PLATE |

| 5. | [10] | 139006-6100 | BLEEDER SCREW |

| 5. | [10] | 139006-6100 | BLEEDER SCREW |

| 7. | [1] | 139709-0100 | O-RING |

| 8. | [1] | 159364-3720 | LEVER SHAFT |

| 9. | [1] | 159362-5720 | CONTROL LEVER |

| 10. | [1] | 016010-0740 | LOCKING WASHER |

| 11/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 11/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 11/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 11/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 11/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 11/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 11/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 11/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 11/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 12. | [1] | 159368-8000 | COILED SPRING |

| 13. | [1] | 159362-1700 | CONTROL LEVER |

| 15. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 16. | [1] | 159364-5100 | CAPSULE |

| 17. | [1] | 159362-4021 | CONTROL LEVER |

| 18. | [1] | 159368-6800 | COILED SPRING |

| 20. | [1] | 159364-3800 | LEVER SHAFT |

| 21. | [2] | 020104-1240 | BLEEDER SCREW |

| 22. | [1] | 159362-0600 | CONTROL LEVER |

| 23. | [2] | 139608-0600 | PACKING RING |

| 23. | [2] | 139608-0600 | PACKING RING |

| 24. | [1] | 159362-0700 | PLAIN WASHER |

| 24B/1. | [0] | 139408-1000 | SHIM D16&8T0.5 |

| 24B/1. | [0] | 139408-1300 | SHIM D16&8T0.2 |

| 24C. | [1] | 159362-0700 | PLAIN WASHER |

| 24D. | [1] | 139308-2100 | PLAIN WASHER |

| 25. | [1] | 159238-4200 | LOCKING WASHER |

| 25B. | [1] | 159238-4200 | LOCKING WASHER |

| 26. | [1] | 159390-3320 | CONTROL LEVER |

| 27. | [1] | 159368-7300 | COILED SPRING |

| 28. | [1] | 159364-6000 | BUSHING |

| 29. | [1] | 014110-8440 | LOCKING WASHER |

| 30. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 31. | [1] | 155644-1301 | BLEEDER SCREW |

| 32. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 35. | [1] | 159361-0520 | GOVERNOR COVER |

| 43. | [1] | 159364-0700 | LEVER SHAFT |

| 44. | [1] | 159364-0800 | BEARING PIN |

| 45. | [2] | 016010-0640 | LOCKING WASHER |

| 46. | [1] | 159363-5720 | TENSIONING LEVER |

| 46/1. | [1] | 159363-5620 | TENSIONING LEVER |

| 46/2. | [1] | 159362-8221 | GUIDE LEVER |

| 46/3. | [1] | 159364-4201 | BEARING PIN |

| 46/4. | [1] | 159368-6201 | COILED SPRING |

| 46/5. | [1] | 016010-0540 | LOCKING WASHER |

| 46/6. | [1] | 016010-0440 | LOCKING WASHER |

| 46/7. | [1] | 159364-4121 | RACK |

| 46/8. | [1] | 159364-4300 | UNION NUT |

| 46/9. | [1] | 159364-4400 | FLAT-HEAD SCREW |

| 46/10. | [1] | 159368-6900 | COILED SPRING |

| 46/11. | [1] | 159368-7000 | COILED SPRING |

| 46/13. | [1] | 016010-0540 | LOCKING WASHER |

| 46/14. | [1] | 159364-1900 | FLAT-HEAD SCREW |

| 46/15. | [1] | 159364-1800 | UNION NUT |

| 46/16. | [1] | 159368-9500 | COILED SPRING |

| 47. | [2] | 016110-1020 | LOCKING WASHER |

| 48. | [2] | 159237-0200 | CAPSULE |

| 51. | [9] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 154611-7420 | RACK SENSOR ASSY |

| 65/1. | [1] | 479775-2920 | RACK SENSOR |

| 65/2. | [1] | 154614-4800 | JOINT CONNECTION |

| 65/3. | [1] | 154614-3100 | BLOCK |

| 65/4. | [1] | 010234-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 65/5. | [1] | 014110-4440 | LOCKING WASHER |

| 65/6. | [1] | 026524-3040 | GASKET |

| 65/7A. | [0] | 029310-6220 | SHIM D11.5&6.5T0.10 |

| 65/7B. | [0] | 029310-6230 | SHIM D11.5&6.5T0.20 |

| 65/7C. | [0] | 029310-6240 | SHIM D11.5&6.5T0.25 |

| 65/7D. | [0] | 029310-6260 | SHIM D11.5&6.4T1.00 |

| 65/7E. | [0] | 029310-6270 | SHIM D11.5&6.4T1.20 |

| 65/7F. | [0] | 029310-6280 | SHIM D11.5&6.4T1.50 |

| 65/8. | [1] | 154614-1900 | UNION NUT |

| 65/9. | [1] | 154614-3300 | BEARING PIN |

| 97. | [1] | 159364-2000 | CAPSULE |

| 100. | [1] | 154100-9220 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 110. | [1] | 154123-2320 | SLIDING PIECE |

| 111/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 111/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 111/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 111/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 111/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 111/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 111/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 111/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 111/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 112. | [1] | 159364-5200 | TERMINAL STUD |

| 130. | [1] | 159367-1900 | GOVERNOR SPRING |

| 131. | [1] | 159367-6300 | GOVERNOR SPRING |

| 132. | [1] | 159369-1900 | COILED SPRING |

| 133. | [1] | 159368-2420 | SPRING PACK |

| 133/1. | [1] | 159364-2200 | GUIDE SLEEVE |

| 133/2. | [1] | 159368-0100 | COILED SPRING |

| 133/3. | [1] | 159368-0600 | COILED SPRING |

| 133/4/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 133/4/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 133/4/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 133/4/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 133/4/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 133/4/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 133/4/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 133/4/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 133/4/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 135. | [1] | 159364-2300 | FLAT-HEAD SCREW |

| 137. | [1] | 159364-2000 | CAPSULE |

| 140. | [1] | 159364-2500 | LEVER SHAFT |

| 145. | [1] | 159233-5700 | UNION NUT |

| 149. | [1] | 159237-5400 | CAPSULE |

| 150. | [1] | 159364-2600 | SLOTTED WASHER |

| 151. | [1] | 159364-2700 | SLOTTED WASHER |

| 155. | [1] | 159363-2721 | STRAP |

| 156. | [1] | 010235-1020 | HEX-SOCKET-HEAD CAP SCREW |

| 160. | [1] | 159362-2020 | LEVER GROUP |

| 160/1. | [1] | 159364-3220 | LEVER SHAFT |

| 160/2. | [1] | 159362-1020 | CONTROL LEVER |

| 160/3. | [1] | 159362-2000 | CONTROL LEVER |

| 160/4. | [2] | 159362-1300 | SHIM |

| 160/4. | [2] | 159362-1300 | SHIM |

| 160/5. | [2] | 016010-0840 | LOCKING WASHER |

| 160/5. | [2] | 016010-0840 | LOCKING WASHER |

| 160/6. | [1] | 159368-6600 | COILED SPRING |

| 162. | [1] | 139411-0600 | SHIM |

| 163. | [1] | 159238-3000 | LOCKING WASHER |

| 164. | [1] | 139610-0800 | PACKING RING |

| 168. | [1] | 159380-0300 | CONTROL LEVER |

| 169. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 170. | [1] | 159380-5120 | CONTROL LEVER |

| 172. | [2] | 020106-1240 | BLEEDER SCREW M6P1.0L12 |

| 173. | [1] | 154013-1700 | BLEEDER SCREW |

| 173B. | [1] | 154013-1800 | BLEEDER SCREW |

| 173C. | [1] | 154013-1900 | BLEEDER SCREW |

| 174. | [1] | 154013-2000 | BLEEDER SCREW |

| 175. | [1] | 154013-3300 | BLEEDER SCREW |

| 176. | [1] | 154011-4000 | UNION NUT |

| 177. | [1] | 154011-4100 | UNION NUT |

| 178. | [1] | 139210-0400 | UNION NUT |

| 220. | [1] | 159368-8420 | HEADLESS SCREW |

| 221. | [1] | 154011-4300 | UNION NUT |

| 222. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 223. | [1] | 154159-2100 | CAP NUT |

| 224. | [1] | 139006-0800 | BLEEDER SCREW |

| 225. | [2] | 029310-8050 | SHIM D13.5&8T0.5 |

| 226. | [1] | 159368-9101 | COILED SPRING |

| 227. | [1] | 159362-6720 | CONTROL LEVER |

| 235. | [1] | 155412-5200 | IMPELLER WHEEL |

| 236. | [1] | 154390-4200 | GASKET |

| 237. | [1] | 154390-2500 | GASKET |

| 250. | [1] | 159398-3020 | BRACKET |

| 251. | [2] | 154339-6300 | COILED SPRING |

| 252. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 257. | [2] | 154156-3100 | TUBE |

| 270. | [1] | 159362-7020 | GUIDE PLATE |

| 271. | [2] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 300. | [1] | 159375-4000 | CAM PLATE |

| 301. | [1] | 016010-0840 | LOCKING WASHER |

| 303. | [1] | 016010-0540 | LOCKING WASHER |

| 311. | [2] | 159237-5400 | CAPSULE |

| 350. | [2] | 139512-0000 | GASKET D17.2&12.2T1.0 |

| 351. | [1] | 139812-0100 | EYE BOLT |

| 355. | [1] | 159396-7420 | BRACKET |

| 356. | [1] | 010110-1640 | BLEEDER SCREW M101.25L16 |

| 357. | [3] | 020106-1440 | BLEEDER SCREW M6P1.0L14 |

Include in #1:

108822-2870

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

105923-4240

ME748151 MITSUBISHI

GOVERNOR

K 14JG MECHANICAL GOVERNOR GOV RLD-J(TICS) GOV

K 14JG MECHANICAL GOVERNOR GOV RLD-J(TICS) GOV

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Caterpillar has discovered that when certain products equipped with the Caterpillar Regeneration System (CRS) are left idling for extended periods of time (greater than 1 hr) and ambient temps are lower than −15° C (5° F), certain conditions may be met which will disable the ability to regenerate the DPF. If the regeneration system cannot activate, the DPF will accumulate too much soot and must eventually be replaced.The issues Caterpillar has identified in extreme cold ambient conditions are the coolant temperature may become too cold for the regeneration system to activate. Also, the pressure lines which connect the DPF inlet section to the DPF intake pressure sensor may collect condensation and freeze. This freezing causes an E1154 (2) or 3609-18 Low DPF #1 Intake Pressure event code. The event code will disable the regeneration until the fault condition goes away.If you suspect low coolant temperature may be contributing to an inability to regenerate the DPF, review the product status report. The product status report is used for investigating the following fault code trend. If coolant temp is the only issue, you will likely see a combination of the following fault codes:

E995 (2) High DPF #1 Soot Loading or 3719-16 Particulate Trap #1 Soot Load Percent : High - moderate severity (2)

Indicates DPF soot load percent has reached 100 percent

E995(3) High DPF #1 soot loading or 3719-0 Particulate Trap #1 Soot Load Percent : High - most severe (3)

Indicates DPF soot load percent has reached 116 percent

E992(3) DPF Active Regeneration Inhibited Due to Temporary System Lockout or 3714-31 Particulate Trap Active Regeneration Inhibited Due to Temporary System Lockout

Indicates DPF soot load reached 116 percent and 10 minutes has passed since that point. Ability to perform automatic or manual regenerations is disabled. Caterpillar Electronic Technician (ET) regeneration is only type of regeneration allowed.

E991 (3) DPF Active Regeneration Inhibited Due to Permanent System Lockout or 3715-31 Particulate Trap Active Regeneration Inhibited Due to Permanent System Lockout

Indicates DPF soot load percent has reached 140 percent. All types of regeneration are disabled. DPF must be replaced as the amount of soot load will damage the DPF if ignited by regeneration process.If you suspect the pressure line for the DPF intake pressure has frozen, you will see a combination of fault codes. These codes will consist of the codes listed above with the addition of the following codes: E1154 (2) DPF #1 intake pressure low and 3609-18 DPF #1 Intake Pressure : Low - moderate severity (2).Solution

Caterpillar recommends the following when extended idling is likely to occur and ambient temperatures are less than −15° C (5° F):

Turn off machine before the end of shift. Before shutting down, perform a manual DPF regeneration and reduce soot load to 0 percent. The soot load must be above the 15 percent threshold needed to activate a manual DPF regeneration.If extended idling is

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Caterpillar has discovered that when certain products equipped with the Caterpillar Regeneration System (CRS) are left idling for extended periods of time (greater than 1 hr) and ambient temps are lower than −15° C (5° F), certain conditions may be met which will disable the ability to regenerate the DPF. If the regeneration system cannot activate, the DPF will accumulate too much soot and must eventually be replaced.The issues Caterpillar has identified in extreme cold ambient conditions are the coolant temperature may become too cold for the regeneration system to activate. Also, the pressure lines which connect the DPF inlet section to the DPF intake pressure sensor may collect condensation and freeze. This freezing causes an E1154 (2) or 3609-18 Low DPF #1 Intake Pressure event code. The event code will disable the regeneration until the fault condition goes away.If you suspect low coolant temperature may be contributing to an inability to regenerate the DPF, review the product status report. The product status report is used for investigating the following fault code trend. If coolant temp is the only issue, you will likely see a combination of the following fault codes:

E995 (2) High DPF #1 Soot Loading or 3719-16 Particulate Trap #1 Soot Load Percent : High - moderate severity (2)

Indicates DPF soot load percent has reached 100 percent

E995(3) High DPF #1 soot loading or 3719-0 Particulate Trap #1 Soot Load Percent : High - most severe (3)

Indicates DPF soot load percent has reached 116 percent

E992(3) DPF Active Regeneration Inhibited Due to Temporary System Lockout or 3714-31 Particulate Trap Active Regeneration Inhibited Due to Temporary System Lockout

Indicates DPF soot load reached 116 percent and 10 minutes has passed since that point. Ability to perform automatic or manual regenerations is disabled. Caterpillar Electronic Technician (ET) regeneration is only type of regeneration allowed.

E991 (3) DPF Active Regeneration Inhibited Due to Permanent System Lockout or 3715-31 Particulate Trap Active Regeneration Inhibited Due to Permanent System Lockout

Indicates DPF soot load percent has reached 140 percent. All types of regeneration are disabled. DPF must be replaced as the amount of soot load will damage the DPF if ignited by regeneration process.If you suspect the pressure line for the DPF intake pressure has frozen, you will see a combination of fault codes. These codes will consist of the codes listed above with the addition of the following codes: E1154 (2) DPF #1 intake pressure low and 3609-18 DPF #1 Intake Pressure : Low - moderate severity (2).Solution

Caterpillar recommends the following when extended idling is likely to occur and ambient temperatures are less than −15° C (5° F):

Turn off machine before the end of shift. Before shutting down, perform a manual DPF regeneration and reduce soot load to 0 percent. The soot load must be above the 15 percent threshold needed to activate a manual DPF regeneration.If extended idling is