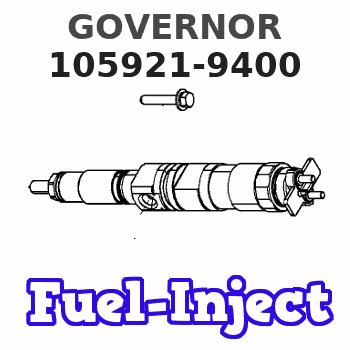

Information governor

BOSCH

9 420 611 775

9420611775

ZEXEL

105921-9400

1059219400

NISSAN-DIESEL

19101Z6719

19101z6719

Rating:

Scheme ###:

| 1. | [1] | 159200-3820 | GOVERNOR HOUSING |

| 2. | [1] | 154007-0200 | ADAPTOR |

| 3. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 4. | [1] | 159232-0401 | PLATE |

| 5. | [5] | 029010-6810 | BLEEDER SCREW |

| 5B. | [1] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 7. | [1] | 016530-1010 | O-RING |

| 8. | [1] | 159205-2821 | LEVER SHAFT |

| 9. | [1] | 159202-4101 | CONTROL LEVER |

| 10. | [1] | 016010-0810 | LOCKING WASHER |

| 11/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 11/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 11/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 11/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 11/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 11/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 11/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 11/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 11/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 12. | [1] | 159215-0500 | COILED SPRING |

| 13. | [1] | 159242-6601 | CONTROL LEVER |

| 15. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 16. | [1] | 159237-5500 | CAPSULE |

| 17. | [1] | 159202-4220 | CONTROL LEVER |

| 18. | [1] | 159215-1900 | COILED SPRING |

| 20. | [1] | 159291-1320 | CONTROL LEVER |

| 21. | [1] | 029311-0210 | SHIM D14&10.1T1 |

| 22. | [1] | 139610-0400 | PACKING RING |

| 23/1. | [0] | 139411-0700 | SHIM D22&11T0.7 |

| 23/1. | [0] | 153305-0100 | SHIM D22&11T0.5 |

| 23/1. | [0] | 153305-0200 | SHIM D22&11T0.4 |

| 23/1. | [0] | 153305-0300 | SHIM D22&11T0.3 |

| 23/1. | [0] | 153305-0400 | SHIM D22&11T0.25 |

| 23/1. | [0] | 153305-0500 | SHIM D22&11T1.0 |

| 23/1. | [0] | 153305-0600 | SHIM D22&11T1.1 |

| 23/1. | [0] | 153305-0700 | SHIM D22&11T2.0 |

| 23/1. | [0] | 153305-1300 | SHIM D22&11T0.951 |

| 23/1. | [0] | 153305-1400 | SHIM D22&11T0.95 |

| 24. | [1] | 159215-3100 | COILED SPRING |

| 25. | [1] | 159235-5800 | CAP |

| 26. | [1] | 159290-9220 | CONTROL LEVER |

| 27. | [1] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

| 35. | [1] | 159250-3520 | GOVERNOR COVER |

| 35/1. | [1] | 159201-5521 | GOVERNOR COVER |

| 35/2. | [1] | 159205-0400 | LEVER SHAFT |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/4. | [1] | 159253-1720 | TENSIONING LEVER |

| 35/4/1. | [1] | 159203-1520 | TENSIONING LEVER |

| 35/4/2. | [1] | 159204-5021 | RACK |

| 35/4/3. | [1] | 159233-0300 | UNION NUT |

| 35/4/4. | [1] | 159234-0300 | FLAT-HEAD SCREW |

| 35/4/5. | [1] | 159216-0000 | COILED SPRING |

| 35/4/6. | [1] | 159216-0100 | COILED SPRING |

| 35/5. | [1] | 159203-6220 | GUIDE LEVER |

| 35/7. | [1] | 159215-1701 | COILED SPRING |

| 35/8. | [1] | 159231-1300 | BEARING PIN |

| 35/9. | [2] | 016010-0610 | LOCKING WASHER |

| 35/10. | [1] | 159238-2900 | BUSHING |

| 51. | [7] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 154612-2220 | RACK SENSOR ASSY |

| 65/1. | [1] | 407945-0220 | RACK SENSOR |

| 65/2. | [1] | 154614-8500 | JOINT CONNECTION |

| 65/3. | [0] | 139406-0700 | SHIM |

| 65/3B. | [0] | 153305-0800 | SHIM D10&6.1T0.2 |

| 65/3C. | [0] | 153305-0900 | SHIM D10&6.1T0.4 |

| 65/4. | [1] | 154614-1900 | UNION NUT |

| 100. | [1] | 154100-9520 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 110. | [1] | 154123-2320 | SLIDING PIECE |

| 111/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 111/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 111/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 111/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 111/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 111/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 111/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 111/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 111/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 112. | [1] | 159236-0200 | TERMINAL STUD |

| 130. | [1] | 159217-0800 | GOVERNOR SPRING |

| 131. | [1] | 159211-7300 | GOVERNOR SPRING |

| 132. | [1] | 159214-0100 | COILED SPRING |

| 133. | [1] | 159219-3220 | SPRING PACK |

| 133/1. | [1] | 159234-5602 | GUIDE SLEEVE |

| 133/2. | [1] | 159212-8900 | COILED SPRING |

| 133/3. | [1] | 159219-1400 | COILED SPRING |

| 133/4/1. | [0] | 029310-9240 | SHIM D11.9&9T0.1 |

| 133/4/1. | [0] | 029310-9250 | SHIM D11.9&9T0.2 |

| 133/4/1. | [0] | 029310-9260 | SHIM D11.9&9T0.25 |

| 133/4/1. | [0] | 029310-9270 | SHIM D11.9&9T1.0 |

| 133/4/1. | [0] | 139409-0100 | SHIM D11.9&9T0.3 |

| 133/4/1. | [0] | 139409-0200 | SHIM D11.9&9T0.5 |

| 133/4/1. | [0] | 139409-0300 | SHIM D11.5&9T0.8 |

| 135. | [1] | 159248-2700 | FLAT-HEAD SCREW |

| 137. | [1] | 159237-5300 | CAPSULE |

| 140. | [1] | 159205-2101 | LEVER SHAFT |

| 145. | [1] | 159233-5700 | UNION NUT |

| 149. | [1] | 159237-5400 | CAPSULE |

| 150. | [1] | 159235-5300 | SLOTTED WASHER |

| 155. | [1] | 159204-5620 | STRAP |

| 156. | [1] | 159233-0520 | BLEEDER SCREW |

| 158. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 160. | [1] | 159252-1121 | LEVER GROUP |

| 160/1. | [1] | 159202-2200 | CONTROL LEVER |

| 160/2. | [1] | 016010-0810 | LOCKING WASHER |

| 160/3. | [1] | 159202-3120 | CONTROL LEVER |

| 160/4. | [1] | 016010-0810 | LOCKING WASHER |

| 160/5. | [1] | 159215-2600 | COILED SPRING |

| 160/6. | [1] | 159205-2922 | LEVER SHAFT |

| 168/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 168/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 168/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 168/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 168/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 168/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 168/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 168/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 168/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 168/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 168/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 169. | [1] | 139410-2300 | SHIM |

| 170. | [1] | 159268-2820 | CONTROL LEVER |

| 172. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 173/1. | [1] | 139006-3500 | BLEEDER SCREW M6P1.0L33 |

| 173/1. | [1] | 139006-3700 | BLEEDER SCREW M6P1.0L34 |

| 173/1. | [1] | 139006-3800 | BLEEDER SCREW M6P1.0L35 |

| 173/1. | [1] | 139006-3900 | BLEEDER SCREW M6P1.0L36 |

| 173/1. | [1] | 139006-5300 | BLEEDER SCREW M6P1.0L31 |

| 173/1. | [1] | 139006-5400 | BLEEDER SCREW M6P1.0L32 |

| 173/1. | [1] | 155615-2500 | BLEEDER SCREW M6P1.0L37 |

| 174. | [1] | 154010-7200 | BLEEDER SCREW M8P1.25L62 |

| 175. | [1] | 154012-5300 | FLAT-HEAD SCREW |

| 176. | [1] | 159233-7500 | UNION NUT |

| 177. | [1] | 154011-2300 | UNION NUT |

| 178. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 159238-3100 | GASKET |

| 250. | [1] | 159222-0220 | BRACKET |

| 251. | [2] | 154338-9200 | COILED SPRING |

| 257. | [2] | 154156-3400 | TUBE |

| 300. | [1] | 159288-6200 | CAM PLATE |

| 301. | [1] | 016010-0840 | LOCKING WASHER |

| 303. | [1] | 016010-0540 | LOCKING WASHER |

| 311. | [1] | 159237-0200 | CAPSULE |

| 320. | [1] | 154420-6320 | MANIFOLD-PRESSURE COMP. |

| 320/1. | [1] | 154412-0821 | DIAPHRAGM HOUSING |

| 320/1A. | [1] | 154412-9401 | SPACER BUSHING |

| 320/2. | [2] | 020106-2540 | BLEEDER SCREW M6P1L25 |

| 320/2. | [2] | 020106-2540 | BLEEDER SCREW M6P1L25 |

| 320/3. | [1] | 020118-3040 | BLEEDER SCREW |

| 320/5. | [1] | 159275-1400 | COILED SPRING |

| 320/6/1. | [1] | 159274-0120 | STOP PIN L125 |

| 320/6/1. | [1] | 159274-0220 | STOP PIN L127.50 |

| 320/6/1. | [1] | 159274-0320 | STOP PIN L128.00 |

| 320/6/1. | [1] | 159274-0420 | STOP PIN L127.00 |

| 320/6/1. | [1] | 159274-0520 | STOP PIN L126.00 |

| 320/6/1. | [1] | 159274-0620 | STOP PIN L129.00 |

| 320/6/1. | [1] | 159274-0720 | STOP PIN L128.50 |

| 320/6/1. | [1] | 159274-0820 | STOP PIN L125.50 |

| 320/6/1. | [1] | 159274-0920 | STOP PIN L126.50 |

| 320/6/1. | [1] | 159274-1120 | STOP PIN L119.5 |

| 320/6/1. | [1] | 159274-1220 | STOP PIN L120 |

| 320/6/1. | [1] | 159274-1320 | STOP PIN L120.5 |

| 320/6/1. | [1] | 159274-1420 | STOP PIN L121 |

| 320/6/1. | [1] | 159274-1520 | STOP PIN L121.5 |

| 320/6/1. | [1] | 159274-1620 | STOP PIN L122 |

| 320/6/1. | [1] | 159274-1720 | STOP PIN L122.5 |

| 320/6/1. | [1] | 159274-1820 | STOP PIN L123 |

| 320/6/1. | [1] | 159274-1920 | STOP PIN L123.5 |

| 320/6/1. | [1] | 159274-4220 | STOP PIN L129.5 |

| 320/6/1. | [1] | 159274-4320 | STOP PIN L130 |

| 320/6/1. | [1] | 159274-4420 | STOP PIN L130.5 |

| 320/6/1. | [1] | 159274-4520 | STOP PIN L131 |

| 320/6/1. | [1] | 159274-4620 | STOP PIN L131.5 |

| 320/6/1. | [1] | 159274-4720 | STOP PIN L132 |

| 320/6/1. | [1] | 159274-4820 | STOP PIN L132.5 |

| 320/6/1. | [1] | 159274-4920 | STOP PIN L133 |

| 320/6/1. | [1] | 159274-5020 | STOP PIN L133.5 |

| 320/7. | [1] | 020306-1640 | BLEEDER SCREW |

| 320/8. | [3] | 020106-2240 | BLEEDER SCREW |

| 320/9. | [1] | 139505-0000 | PLAIN WASHER |

| 320/11. | [1] | 154400-8521 | DIAPHRAGM |

| 320/14. | [1] | 154406-5500 | SLOTTED WASHER |

| 320/15. | [1] | 013030-6010 | UNION NUT |

| 320/16. | [1] | 154402-4500 | COILED SPRING |

| 320/17. | [2] | 154413-2600 | GASKET |

| 320/18. | [1] | 154404-5100 | COVER |

| 320/19. | [1] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 320/20. | [2] | 139006-7000 | BLEEDER SCREW |

| 320/21. | [2] | 014110-6440 | LOCKING WASHER |

| 320/24. | [2] | 020106-2240 | BLEEDER SCREW |

| 320/27. | [1] | 029731-0180 | EYE BOLT |

| 320/28. | [2] | 026510-1340 | GASKET D13.4&10.2T1 |

| 320/29. | [1] | 154413-2501 | GASKET |

| 320/43. | [1] | 159226-4500 | SPACER RING |

| 320/44. | [1] | 014010-5140 | PLAIN WASHER D12&5.5T0.8 |

| 320/45. | [1] | 029331-8040 | GASKET |

| 320/46. | [1] | 154406-5800 | FLAT-HEAD SCREW |

| 320/47. | [1] | 014110-6440 | LOCKING WASHER |

| 320/54. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 320/55. | [1] | 154404-4800 | FLAT-HEAD SCREW |

| 320/61. | [1] | 154035-1600 | CAP NUT |

| 320/62. | [1] | 154404-4400 | FLAT-HEAD SCREW |

| 320/63. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 320/64. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

Include in #1:

101696-9790

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

If complete injector sets are replacedon 3412E machines:

PART Hours/Age, whichevercomes first Caterpillar Dealer Suggested Customer Suggested

Parts (D/N) Labor Hrs (Cost) Parts Labor Hrs Parts (C/L) Labor Hrs (Sell)

0-4000 0-48 mos 100% 7 0 0 0 0

4001-8000 0-48 mos 33.3% 3.5 0 0 50% 3.5

* This is a 7-hour job. Actual hourspermitted up to maximums noted above.PARTS DISPOSITION

NACD Dealers, return Injector(s) to:Caterpillar Inc.Attn: Fergal O?Shea ? PS50424

Service Claims Room

8201 N. University

Peoria, IL 61615 ***** All Other Dealers *****

Handle the parts in accordance with yourWarranty Bulletin on warranty parts handling.

Attach. (1-Rework Procedure)Rework Procedure

The two tests below provide the appropriateinjector troubleshooting and repair steps for injector updates.

Use "Test for Cylinder Cutout" to determine ifindividual injector replacements (using original injector part) are needed.

Use "Test for Leakage from Poppet Valve" to determineif full injector sets (using new injector parts and software change) areappropriate for repair.

Test for Cylinder Cutout:

Warm the engine out of Cold Mode.

Connect Caterpillar Electronic Technician (ET)to the engine while the engine is running.

Ensure that the engine speed is 1200 rpm +/- 125rpm. An extremely rough running engine well need to be diagnosed by othermethods.

Cut out one bank of cylinders. Note engine rpmand the fuel position on the ET screen at that time.

Cut out one of the remaining cylinders from thecylinder bank that is running. Allow the engine to stabilize and note thefuel position.

Give power back to that cylinder. Allow the engineto stabilize and note the fuel position.

Repeat steps 5 through 6 until the cylinder bankhas been completely checked.

Power all cylinders. Allow the engine to stabilize.

Cut out the other cylinder bank and repeat steps5 through 8.

Repeat steps 4 through 9 with the engine at 2000rpm.

Compare the results from the fuel position fromeach cylinder.

If the cylinder was cut out and the fuel positiondid not change, the cylinder may not have producing power. This cylinderwould be suspect.

When you are finished with the test, decreaseengine rpm to low idle and shut the engine off.

Replace any suspect injector with a similar originalinjector. Install new seals for the injector and the jumper tube duringthis repair. The injector repair procedure is found in Special InstructionREHS0116.

If this is the third injector failure,related to this Service Letter, and to the same engine serial number within120 calendar days, replace all the injectors and software following SpecialInstruction article REHS1385.It is also possible that multiple injectors arefunctioning improperly. Complete "Test for Leakage from Poppet Valve" inorder to evaluate potential excessive injector leakage and need for fuelsystem conversion.Test for Leakage from PoppetValve:

Warm engine out of Cold Mode to normal operatingtemperature.

Turn off the engine.

Remove the valve cover bolts in preparation toobserve the injectors. Leave covers in place.

: Hot oil and components can causepersonal injury. Do not allow hot oil or components to contact skin.

Restart the engine and run at low idle with noload.

Use the ET service tool in order to perform theoverride test for the injection actuation system. Increase injection actuationpressure to the maximum value.

Observe all of the injectors under each valvecover for leakage at the spill port. A small amount of dripping is acceptable.However, a continuous stream of oil is an indication of excessive leakageof the poppet valve. Only leaks at the spill port

PART Hours/Age, whichevercomes first Caterpillar Dealer Suggested Customer Suggested

Parts (D/N) Labor Hrs (Cost) Parts Labor Hrs Parts (C/L) Labor Hrs (Sell)

0-4000 0-48 mos 100% 7 0 0 0 0

4001-8000 0-48 mos 33.3% 3.5 0 0 50% 3.5

* This is a 7-hour job. Actual hourspermitted up to maximums noted above.PARTS DISPOSITION

NACD Dealers, return Injector(s) to:Caterpillar Inc.Attn: Fergal O?Shea ? PS50424

Service Claims Room

8201 N. University

Peoria, IL 61615 ***** All Other Dealers *****

Handle the parts in accordance with yourWarranty Bulletin on warranty parts handling.

Attach. (1-Rework Procedure)Rework Procedure

The two tests below provide the appropriateinjector troubleshooting and repair steps for injector updates.

Use "Test for Cylinder Cutout" to determine ifindividual injector replacements (using original injector part) are needed.

Use "Test for Leakage from Poppet Valve" to determineif full injector sets (using new injector parts and software change) areappropriate for repair.

Test for Cylinder Cutout:

Warm the engine out of Cold Mode.

Connect Caterpillar Electronic Technician (ET)to the engine while the engine is running.

Ensure that the engine speed is 1200 rpm +/- 125rpm. An extremely rough running engine well need to be diagnosed by othermethods.

Cut out one bank of cylinders. Note engine rpmand the fuel position on the ET screen at that time.

Cut out one of the remaining cylinders from thecylinder bank that is running. Allow the engine to stabilize and note thefuel position.

Give power back to that cylinder. Allow the engineto stabilize and note the fuel position.

Repeat steps 5 through 6 until the cylinder bankhas been completely checked.

Power all cylinders. Allow the engine to stabilize.

Cut out the other cylinder bank and repeat steps5 through 8.

Repeat steps 4 through 9 with the engine at 2000rpm.

Compare the results from the fuel position fromeach cylinder.

If the cylinder was cut out and the fuel positiondid not change, the cylinder may not have producing power. This cylinderwould be suspect.

When you are finished with the test, decreaseengine rpm to low idle and shut the engine off.

Replace any suspect injector with a similar originalinjector. Install new seals for the injector and the jumper tube duringthis repair. The injector repair procedure is found in Special InstructionREHS0116.

If this is the third injector failure,related to this Service Letter, and to the same engine serial number within120 calendar days, replace all the injectors and software following SpecialInstruction article REHS1385.It is also possible that multiple injectors arefunctioning improperly. Complete "Test for Leakage from Poppet Valve" inorder to evaluate potential excessive injector leakage and need for fuelsystem conversion.Test for Leakage from PoppetValve:

Warm engine out of Cold Mode to normal operatingtemperature.

Turn off the engine.

Remove the valve cover bolts in preparation toobserve the injectors. Leave covers in place.

: Hot oil and components can causepersonal injury. Do not allow hot oil or components to contact skin.

Restart the engine and run at low idle with noload.

Use the ET service tool in order to perform theoverride test for the injection actuation system. Increase injection actuationpressure to the maximum value.

Observe all of the injectors under each valvecover for leakage at the spill port. A small amount of dripping is acceptable.However, a continuous stream of oil is an indication of excessive leakageof the poppet valve. Only leaks at the spill port