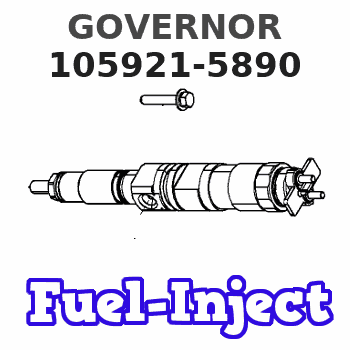

Information governor

BOSCH

9 420 610 254

9420610254

ZEXEL

105921-5890

1059215890

MITSUBISHI

ME730789

me730789

Rating:

Scheme ###:

| 1. | [1] | 159200-3220 | GOVERNOR HOUSING |

| 2. | [1] | 154007-0200 | ADAPTOR |

| 3. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 4. | [1] | 159232-0401 | PLATE |

| 5. | [5] | 029010-6810 | BLEEDER SCREW |

| 5B. | [1] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 7. | [1] | 016530-1010 | O-RING |

| 8. | [1] | 159205-2821 | LEVER SHAFT |

| 9. | [1] | 159202-2900 | CONTROL LEVER |

| 10. | [1] | 016010-0810 | LOCKING WASHER |

| 11/1. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 11/1. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 11/1. | [0] | 029311-0430 | SHIM D18&10.3T0.30 |

| 11/1. | [0] | 029311-0440 | SHIM D18&10.3T0.40 |

| 11/1. | [0] | 029311-0450 | SHIM D18&10.3T0.25 |

| 11/1. | [0] | 029311-0460 | SHIM D18&10.3T0.35 |

| 11/1. | [0] | 139410-3300 | SHIM D18&10.3T0.6 |

| 11/1. | [0] | 139410-3400 | SHIM D18&10.3T0.8 |

| 11/1. | [0] | 139410-3500 | SHIM D18&10.3T0.9 |

| 12. | [1] | 159215-0500 | COILED SPRING |

| 13. | [1] | 159242-6601 | CONTROL LEVER |

| 15. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 16. | [1] | 159237-5200 | CAPSULE |

| 17. | [1] | 159202-3320 | CONTROL LEVER |

| 18. | [1] | 159215-0600 | COILED SPRING |

| 20. | [1] | 159242-0920 | CONTROL LEVER |

| 21. | [1] | 159242-0600 | BUSHING |

| 22. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 23/1. | [0] | 139410-1300 | SHIM D20.8&10.2T0.3 |

| 23/1. | [0] | 139410-1700 | SHIM D20.8&10.2T0.2 |

| 23/1. | [0] | 139410-1800 | SHIM D20.8&10.2T0.4 |

| 23/1. | [0] | 139410-2800 | SHIM D20.8&10.2T0.6 |

| 23/1. | [0] | 139410-3700 | SHIM D20.8&10.2T0.9 |

| 24. | [1] | 159215-3000 | COILED SPRING |

| 25. | [1] | 159235-5800 | CAP |

| 26. | [1] | 159249-0320 | CONTROL LEVER |

| 27. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 35. | [1] | 159251-7520 | GOVERNOR COVER |

| 35/1. | [1] | 159201-5521 | GOVERNOR COVER |

| 35/2. | [1] | 159205-0400 | LEVER SHAFT |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/3. | [2] | 159237-0200 | CAPSULE |

| 35/4. | [1] | 159253-1120 | TENSIONING LEVER |

| 35/4/1. | [1] | 159203-1120 | TENSIONING LEVER |

| 35/4/2. | [1] | 159204-5021 | RACK |

| 35/4/3. | [1] | 159233-0300 | UNION NUT |

| 35/4/4. | [1] | 159234-0300 | FLAT-HEAD SCREW |

| 35/4/5. | [1] | 159216-0000 | COILED SPRING |

| 35/4/6. | [1] | 159216-0100 | COILED SPRING |

| 35/5. | [1] | 159203-6020 | GUIDE LEVER |

| 35/7. | [1] | 159215-1701 | COILED SPRING |

| 35/8. | [1] | 159231-2000 | BEARING PIN |

| 35/9. | [2] | 016010-0610 | LOCKING WASHER |

| 51. | [6] | 020106-3840 | BLEEDER SCREW |

| 51B. | [1] | 020106-4040 | BLEEDER SCREW |

| 65. | [1] | 154050-1720 | STOPPING DEVICE |

| 100. | [1] | 154101-0420 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 110. | [1] | 154123-2320 | SLIDING PIECE |

| 111/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 111/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 111/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 111/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 111/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 111/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 111/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 111/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 111/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 112. | [1] | 159236-0200 | TERMINAL STUD |

| 130. | [1] | 159210-5800 | GOVERNOR SPRING |

| 131. | [1] | 159211-3300 | GOVERNOR SPRING |

| 132. | [1] | 159214-0100 | COILED SPRING |

| 133. | [1] | 159212-4920 | SPRING PACK |

| 133/1. | [1] | 159234-5602 | GUIDE SLEEVE |

| 133/2. | [1] | 159212-4500 | COILED SPRING |

| 133/3. | [1] | 159212-3500 | COILED SPRING |

| 133/4/1. | [0] | 029310-9240 | SHIM D11.9&9T0.1 |

| 133/4/1. | [0] | 029310-9250 | SHIM D11.9&9T0.2 |

| 133/4/1. | [0] | 029310-9260 | SHIM D11.9&9T0.25 |

| 133/4/1. | [0] | 029310-9270 | SHIM D11.9&9T1.0 |

| 133/4/1. | [0] | 139409-0100 | SHIM D11.9&9T0.3 |

| 133/4/1. | [0] | 139409-0200 | SHIM D11.9&9T0.5 |

| 133/4/1. | [0] | 139409-0300 | SHIM D11.5&9T0.8 |

| 135. | [1] | 159248-2700 | FLAT-HEAD SCREW |

| 137. | [1] | 159237-5300 | CAPSULE |

| 140. | [1] | 159205-2101 | LEVER SHAFT |

| 145. | [1] | 159233-5700 | UNION NUT |

| 149. | [1] | 159237-5400 | CAPSULE |

| 150. | [1] | 159235-5300 | SLOTTED WASHER |

| 155. | [1] | 159204-5620 | STRAP |

| 156. | [1] | 159233-5800 | BLEEDER SCREW |

| 158. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 160. | [1] | 159252-1821 | LEVER GROUP |

| 160/1. | [1] | 159205-3511 | LEVER SHAFT |

| 160/2. | [1] | 159202-4420 | CONTROL LEVER |

| 160/3. | [1] | 029310-6030 | SHIM D11.5&6.2T0.2 |

| 160/4. | [1] | 159202-4520 | CONTROL LEVER |

| 160/5. | [1] | 159202-2200 | CONTROL LEVER |

| 160/6. | [1] | 159215-2600 | COILED SPRING |

| 160/7. | [1] | 159215-3600 | COILED SPRING |

| 160/8. | [1] | 016010-0810 | LOCKING WASHER |

| 160/9. | [1] | 014020-6140 | PLAIN WASHER |

| 160/10. | [1] | 016010-0610 | LOCKING WASHER |

| 160/11. | [1] | 016010-0810 | LOCKING WASHER |

| 168/1. | [0] | 139410-1200 | SHIM D26&10.2T0.3 |

| 168/1. | [0] | 139410-1900 | SHIM D26&10.2T0.2 |

| 168/1. | [0] | 139410-2000 | SHIM D26&10.2T0.4 |

| 168/1. | [0] | 139410-2400 | SHIM D26&10.2T0.35 |

| 168/1. | [0] | 139410-2500 | SHIM D26&10.2T0.25 |

| 168/1. | [0] | 139410-2900 | SHIM D26&10.2T0.6 |

| 169. | [1] | 139410-2100 | SHIM |

| 170. | [1] | 159264-2520 | CONTROL LEVER |

| 172. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 173/1. | [1] | 139006-3500 | BLEEDER SCREW M6P1.0L33 |

| 173/1. | [1] | 139006-3700 | BLEEDER SCREW M6P1.0L34 |

| 173/1. | [1] | 139006-3800 | BLEEDER SCREW M6P1.0L35 |

| 173/1. | [1] | 139006-3900 | BLEEDER SCREW M6P1.0L36 |

| 173/1. | [1] | 139006-5300 | BLEEDER SCREW M6P1.0L31 |

| 173/1. | [1] | 139006-5400 | BLEEDER SCREW M6P1.0L32 |

| 173/1. | [1] | 155615-2500 | BLEEDER SCREW M6P1.0L37 |

| 174. | [1] | 154010-7200 | BLEEDER SCREW M8P1.25L62 |

| 175. | [1] | 154010-2900 | BLEEDER SCREW |

| 176. | [1] | 159225-8600 | UNION NUT |

| 177. | [1] | 154011-2300 | UNION NUT |

| 178. | [1] | 154011-0100 | HEXAGON NUT |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 159238-3100 | GASKET |

| 250. | [1] | 159227-1020 | BRACKET |

| 251. | [2] | 159243-7000 | COILED SPRING |

| 253. | [1] | 139010-0000 | STUD |

| 257. | [2] | 154156-1800 | TUBE |

| 300. | [1] | 159280-3300 | CAM PLATE |

| 301. | [1] | 016010-0840 | LOCKING WASHER |

| 303. | [1] | 016010-0540 | LOCKING WASHER |

| 311. | [1] | 159237-0200 | CAPSULE |

| 320. | [1] | 154419-0421 | MANIFOLD-PRESSURE COMP. |

| 320/1. | [1] | 154412-0821 | DIAPHRAGM HOUSING |

| 320/1A. | [1] | 154413-2701 | SPACER BUSHING |

| 320/2. | [1] | 020106-2240 | BLEEDER SCREW |

| 320/2A. | [1] | 020106-2540 | BLEEDER SCREW M6P1L25 |

| 320/3. | [1] | 020118-3040 | BLEEDER SCREW |

| 320/5. | [1] | 159275-1400 | COILED SPRING |

| 320/6/1. | [1] | 159274-0120 | STOP PIN L125 |

| 320/6/1. | [1] | 159274-0220 | STOP PIN L127.50 |

| 320/6/1. | [1] | 159274-0320 | STOP PIN L128.00 |

| 320/6/1. | [1] | 159274-0420 | STOP PIN L127.00 |

| 320/6/1. | [1] | 159274-0520 | STOP PIN L126.00 |

| 320/6/1. | [1] | 159274-0620 | STOP PIN L129.00 |

| 320/6/1. | [1] | 159274-0720 | STOP PIN L128.50 |

| 320/6/1. | [1] | 159274-0820 | STOP PIN L125.50 |

| 320/6/1. | [1] | 159274-0920 | STOP PIN L126.50 |

| 320/6/1. | [1] | 159274-1120 | STOP PIN L119.5 |

| 320/6/1. | [1] | 159274-1220 | STOP PIN L120 |

| 320/6/1. | [1] | 159274-1320 | STOP PIN L120.5 |

| 320/6/1. | [1] | 159274-1420 | STOP PIN L121 |

| 320/6/1. | [1] | 159274-1520 | STOP PIN L121.5 |

| 320/6/1. | [1] | 159274-1620 | STOP PIN L122 |

| 320/6/1. | [1] | 159274-1720 | STOP PIN L122.5 |

| 320/6/1. | [1] | 159274-1820 | STOP PIN L123 |

| 320/6/1. | [1] | 159274-1920 | STOP PIN L123.5 |

| 320/6/1. | [1] | 159274-4220 | STOP PIN L129.5 |

| 320/6/1. | [1] | 159274-4320 | STOP PIN L130 |

| 320/6/1. | [1] | 159274-4420 | STOP PIN L130.5 |

| 320/6/1. | [1] | 159274-4520 | STOP PIN L131 |

| 320/6/1. | [1] | 159274-4620 | STOP PIN L131.5 |

| 320/6/1. | [1] | 159274-4720 | STOP PIN L132 |

| 320/6/1. | [1] | 159274-4820 | STOP PIN L132.5 |

| 320/6/1. | [1] | 159274-4920 | STOP PIN L133 |

| 320/6/1. | [1] | 159274-5020 | STOP PIN L133.5 |

| 320/7. | [1] | 020306-1640 | BLEEDER SCREW |

| 320/8. | [2] | 020106-2240 | BLEEDER SCREW |

| 320/8A. | [1] | 020106-2540 | BLEEDER SCREW M6P1L25 |

| 320/9. | [1] | 139505-0000 | PLAIN WASHER |

| 320/11. | [1] | 154400-8521 | DIAPHRAGM |

| 320/14. | [1] | 154406-5500 | SLOTTED WASHER |

| 320/15. | [1] | 013030-6010 | UNION NUT |

| 320/16. | [1] | 154402-0900 | COILED SPRING |

| 320/17. | [2] | 154413-2600 | GASKET |

| 320/18. | [1] | 154404-5000 | COVER |

| 320/19. | [1] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 320/20. | [2] | 139006-7000 | BLEEDER SCREW |

| 320/21. | [2] | 014110-6440 | LOCKING WASHER |

| 320/24. | [2] | 020106-2540 | BLEEDER SCREW M6P1L25 |

| 320/27. | [1] | 029731-0180 | EYE BOLT |

| 320/28. | [2] | 026510-1340 | GASKET D13.4&10.2T1 |

| 320/29. | [1] | 154413-2501 | GASKET |

| 320/43. | [1] | 159226-4500 | SPACER RING |

| 320/44. | [1] | 014010-5140 | PLAIN WASHER D12&5.5T0.8 |

| 320/45. | [1] | 029331-8040 | GASKET |

| 320/46. | [1] | 154406-5800 | FLAT-HEAD SCREW |

| 320/47. | [1] | 014110-6440 | LOCKING WASHER |

| 320/54. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 320/55. | [1] | 154404-4800 | FLAT-HEAD SCREW |

| 320/61. | [1] | 154035-1600 | CAP NUT |

| 320/62. | [1] | 154404-4400 | FLAT-HEAD SCREW |

| 320/63. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 320/64. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 340. | [1] | 159220-8600 | BRACKET |

| 341. | [2] | 020104-1040 | BLEEDER SCREW |

| 401. | [1] | 159226-5520 | BRACKET |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105921-5890

ME730789 MITSUBISHI

GOVERNOR

K 14JK MECHANICAL GOVERNOR GOV RLD GOV

K 14JK MECHANICAL GOVERNOR GOV RLD GOV

Information:

Introduction

The Environmental Protection Agency (EPA) has mandated that a DEF quality sensor must be installed on certain engines built after 2016. This new DEF quality sensor is integrated into the DEF header inside the DEF tank. The new style DEF header utilizes CAN C communication, so the wiring to the DEF header has been slightly modified on product going forward. However, the Dosing Control Unit (DCU) remains compatible to both setups with the latest engine software. ( 507-7605 Engine Software (24V DCU) or 507-7546 Engine Software (12V DCU)). As part of the DEF quality sensor implementation, a new configuration parameter setting is used on the engine Electronic Control Module (ECM) in Cat ET to identify whether a DEF quality sensor is"installed" or "not installed". Below are some different diagnostic codes for incompatible hardware and configuration setting as well as different service scenarios that may be encountered with this change and how to resolve any issues in these particular service scenarios. In addition to this Special Instruction, there is a video detailing these changes posted on Cat Channel 1.Diagnostic Codes When Parts/Settings Are Not Compatible

DEF quality header not installed but configuration set to "installed".

Table 1

J1939 Code and Description CDL Code and Description

1235-9

J1939 Network #3 : Abnormal Update Rate 5856-9

J1939 Network #3 : Abnormal Update Rate DEF quality header installed but configuration set to not installed.

Table 2

J1939 Code and Description CDL Code and Description

1761-3

Aftertreatment 1 Diesel Exhaust Fluid Tank Level : Voltage Above Normal 3130-3

Aftertreatment #1 SCR Catalyst Reagent Tank #1 Level Sensor : Voltage Above Normal

3031-3

Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature : Voltage Above Normal 3134-3

Aftertreatment #1 SCR Catalyst Reagent Tank #1 Temperature Sensor : Voltage Above Normal DEF Quality Sensor Service Scenarios

Replacement Industrial Engine (2016 and earlier builds)

Replace with new engine (old engine no longer serviceable). Update to DEF quality sensor by installing a new DEF header, wiring harness, and DCU software and changing DEF quality sensor configuration status to "installed" in Cat ET.Replacement Machine Engine (2016 and Earlier Builds)

Replace with older service replacement Engine Arrangement Complete (EAC) engine (no other changes needed, confirm that DEF quality sensor configuration is set to "not installed" in CAT ET).

If dealer orders new EAC, update to DEF quality sensor is required (below scenario).Replacement Engine (2017and Future Builds)

Replace with latest EAC engine.Install DEF Quality Sensor on 2016 or Earlier Builds

Requires DCU software update, Pump, Electronic, and Tank Unit (PETU) wiring harness update, change DEF quality sensor configuration status to"installed".Replace DCU

No effect - new DCU hardware and software is compatible to both DEF headers.Replace Engine ECM

No effect when using ECM replacement file.

If engine ECM is replaced without the ECM replacement file, the DEF quality sensor configuration setting will default to "not installed" and may need to be updated if machine utilizes DEF quality sensor (requires Factory Passwords to change).Replace Wiring Harness

No effect - both new and old harness part numbers are available. Order same part number that is removed.

The Environmental Protection Agency (EPA) has mandated that a DEF quality sensor must be installed on certain engines built after 2016. This new DEF quality sensor is integrated into the DEF header inside the DEF tank. The new style DEF header utilizes CAN C communication, so the wiring to the DEF header has been slightly modified on product going forward. However, the Dosing Control Unit (DCU) remains compatible to both setups with the latest engine software. ( 507-7605 Engine Software (24V DCU) or 507-7546 Engine Software (12V DCU)). As part of the DEF quality sensor implementation, a new configuration parameter setting is used on the engine Electronic Control Module (ECM) in Cat ET to identify whether a DEF quality sensor is"installed" or "not installed". Below are some different diagnostic codes for incompatible hardware and configuration setting as well as different service scenarios that may be encountered with this change and how to resolve any issues in these particular service scenarios. In addition to this Special Instruction, there is a video detailing these changes posted on Cat Channel 1.Diagnostic Codes When Parts/Settings Are Not Compatible

DEF quality header not installed but configuration set to "installed".

Table 1

J1939 Code and Description CDL Code and Description

1235-9

J1939 Network #3 : Abnormal Update Rate 5856-9

J1939 Network #3 : Abnormal Update Rate DEF quality header installed but configuration set to not installed.

Table 2

J1939 Code and Description CDL Code and Description

1761-3

Aftertreatment 1 Diesel Exhaust Fluid Tank Level : Voltage Above Normal 3130-3

Aftertreatment #1 SCR Catalyst Reagent Tank #1 Level Sensor : Voltage Above Normal

3031-3

Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature : Voltage Above Normal 3134-3

Aftertreatment #1 SCR Catalyst Reagent Tank #1 Temperature Sensor : Voltage Above Normal DEF Quality Sensor Service Scenarios

Replacement Industrial Engine (2016 and earlier builds)

Replace with new engine (old engine no longer serviceable). Update to DEF quality sensor by installing a new DEF header, wiring harness, and DCU software and changing DEF quality sensor configuration status to "installed" in Cat ET.Replacement Machine Engine (2016 and Earlier Builds)

Replace with older service replacement Engine Arrangement Complete (EAC) engine (no other changes needed, confirm that DEF quality sensor configuration is set to "not installed" in CAT ET).

If dealer orders new EAC, update to DEF quality sensor is required (below scenario).Replacement Engine (2017and Future Builds)

Replace with latest EAC engine.Install DEF Quality Sensor on 2016 or Earlier Builds

Requires DCU software update, Pump, Electronic, and Tank Unit (PETU) wiring harness update, change DEF quality sensor configuration status to"installed".Replace DCU

No effect - new DCU hardware and software is compatible to both DEF headers.Replace Engine ECM

No effect when using ECM replacement file.

If engine ECM is replaced without the ECM replacement file, the DEF quality sensor configuration setting will default to "not installed" and may need to be updated if machine utilizes DEF quality sensor (requires Factory Passwords to change).Replace Wiring Harness

No effect - both new and old harness part numbers are available. Order same part number that is removed.