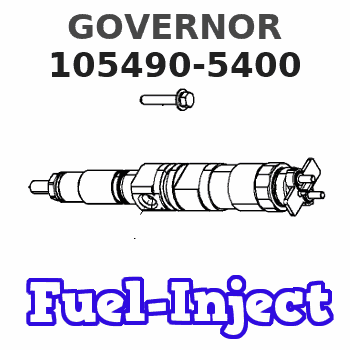

Information governor

BOSCH

9 420 613 553

9420613553

ZEXEL

105490-5400

1054905400

MITSUBISHI

ME723166

me723166

Rating:

Scheme ###:

| 1. | [1] | 154000-6800 | GOVERNOR HOUSING |

| 4. | [1] | 154366-2820 | CONTROL LEVER |

| 4. | [1] | 154366-2820 | CONTROL LEVER |

| 4/1. | [1] | 154304-3500 | CONTROL LEVER |

| 4/2. | [1] | 154352-2000 | BLEEDER SCREW |

| 4/3. | [1] | 154366-2800 | CONTROL LEVER |

| 4/4. | [1] | 029311-0230 | SHIM D18&10.3T0.5 |

| 4/5. | [1] | 154321-1500 | BUSHING |

| 4/6. | [1] | 154327-4600 | COILED SPRING |

| 4/7. | [1] | 154322-0100 | CAP |

| 4/8. | [1] | 029311-0220 | SHIM D18&10.3T0.2 |

| 4/9. | [1] | 154324-2700 | LEVER SHAFT |

| 4/10. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 4/11. | [1] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

| 6. | [1] | 154007-0200 | ADAPTOR |

| 7. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 9. | [1] | 154350-1800 | PLATE |

| 10. | [5] | 029010-6810 | BLEEDER SCREW |

| 11. | [1] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 12. | [1] | 154010-7800 | BLEEDER SCREW |

| 13. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 14. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 14B. | [1] | 154011-2300 | UNION NUT |

| 35. | [1] | 154513-2320 | GOVERNOR COVER |

| 35/2. | [1] | 154321-1800 | BUSHING |

| 35/3. | [1] | 029621-0080 | PACKING RING |

| 38. | [1] | 154031-3500 | FLAT-HEAD SCREW |

| 39. | [1] | 154011-1600 | UNION NUT |

| 47. | [1] | 154036-0300 | CAPSULE |

| 48. | [1] | 154010-7100 | BLEEDER SCREW M10P1.25L47 |

| 48B. | [1] | 154010-7700 | BLEEDER SCREW M10P1.25L51 |

| 49. | [1] | 154011-2200 | UNION NUT |

| 50. | [1] | 155615-1600 | BLEEDER SCREW |

| 51. | [4] | 020106-3840 | BLEEDER SCREW |

| 52. | [1] | 010006-5040 | BLEEDER SCREW M6P1L50 |

| 52B. | [1] | 010006-5540 | BLEEDER SCREW M6P1L55 4T |

| 53. | [1] | 154010-7400 | BLEEDER SCREW M8P1.25L55 |

| 54. | [2] | 014110-6440 | LOCKING WASHER |

| 65. | [1] | 155404-5700 | CAP |

| 70. | [1] | 154055-0520 | HEADLESS SCREW |

| 80. | [1] | 154060-4900 | COVER |

| 82. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 83. | [1] | 029020-6210 | BLEEDER SCREW |

| 84. | [1] | 020006-1840 | BLEEDER SCREW M6P1L18 |

| 86. | [1] | 029020-6240 | BLEEDER SCREW |

| 100. | [1] | 154100-9520 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-7000 | GOVERNOR SPRING |

| 132. | [1] | 154154-0800 | COILED SPRING |

| 140. | [1] | 154180-0720 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-3801 | SWIVELLING LEVER |

| 151. | [1] | 154204-2001 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156/1. | [0] | 029311-1110 | SHIM D17&11T0.1 |

| 156/1. | [0] | 029311-1120 | SHIM D17&11T0.2 |

| 156/1. | [0] | 029311-1130 | SHIM D17&11T0.3 |

| 157. | [1] | 154204-3400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-0900 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154216-2620 | FORK LEVER |

| 173. | [1] | 016010-0540 | LOCKING WASHER |

| 174. | [1] | 154230-4720 | STRAP |

| 179. | [1] | 154238-0301 | BEARING PIN |

| 180. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-5300 | TENSIONING LEVER |

| 182. | [1] | 154237-0900 | BEARING PIN |

| 183. | [2] | 154237-0600 | BUSHING |

| 190. | [1] | 154360-2800 | CONTROL LEVER |

| 191. | [1] | 154340-0120 | CONTROL LEVER |

| 192. | [1] | 020006-1670 | BLEEDER SCREW M6P1L16 7T |

| 193. | [1] | 154368-7220 | CONTROL LEVER |

| 194. | [2] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

| 203/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 203/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 203/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 203/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 203/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 203/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 203/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 203/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 203/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 203/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 203/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 205. | [1] | 154324-4500 | LEVER SHAFT |

| 207. | [1] | 154326-0300 | CONTROL LEVER |

| 211. | [1] | 016010-0840 | LOCKING WASHER |

| 220. | [1] | 154050-1220 | HEADLESS SCREW |

| 221. | [1] | 029201-2140 | UNION NUT |

| 222. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 223. | [1] | 154159-1200 | CAP NUT |

| 235. | [1] | 155412-5200 | IMPELLER WHEEL |

| 236. | [1] | 154390-1300 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 248. | [1] | 154357-5220 | BRACKET |

| 361. | [1] | 154370-2700 | BRACKET |

| 362. | [4] | 010038-1240 | BLEEDER SCREW |

| 362. | [4] | 010038-1240 | BLEEDER SCREW |

| 363. | [4] | 014110-8440 | LOCKING WASHER |

| 363. | [4] | 014110-8440 | LOCKING WASHER |

| 364. | [1] | 154370-2800 | BRACKET |

| 400. | [1] | 154354-7720 | CONTROL LEVER |

| 401. | [2] | 154354-7800 | BUSHING |

| 401. | [2] | 154354-7800 | BUSHING |

| 402. | [1] | 154354-7210 | TENSIONING BRACKET |

| 403. | [1] | 154354-7410 | BRACKET |

| 404. | [2] | 010138-1240 | BLEEDER SCREW M8P1.25L12 |

| 405. | [2] | 014110-8440 | LOCKING WASHER |

| 835S. | [1] | 154062-1700 | CAP D20L32 |

| 836S. | [1] | 154062-1800 | CAP D20L27 |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105490-5400

ME723166 MITSUBISHI

GOVERNOR

K 14JN MECHANICAL GOVERNOR GOV RFD GOV

K 14JN MECHANICAL GOVERNOR GOV RFD GOV

Information:

2-302. Dismantle the vee-belt idler or cover. Slacken the screw on the injection pump drive with special spanner No. 110310.Fig. 2-30

2-31

2-323. Slowly rotate the injection pump shaft in the direction of normal rotation until the pump starts to deliver fuel. (Use double spanner No. 110330 or a 19 mm socket spanner)Fig. 2-31 and 2-324. Check that fuel comes out from overflow pipe (when operating test unit or pump) only in droplets at intervals of 5-8 seconds.5. Retain the injection pump shaft in this position and tighten the screws on the injection pump drive, using special spanner No. 110310.6. Re-check the fuel-injection point and correct, if necessary. Turn off the high-pressure tester.

2-337. Assemble the vee-belt idler or cover with a new rubber O-ring. Dismantle the timing device. Connect the fuel lines, free from tension, and assemble the cover on the injection pump.Fig. 2-33Testing The Injection Nozzle (by testing outfit)

Injector is removed.

2-341. Connect injector to outfit.Fig. 2-34

2-352. With pressure gauge cut in, press outfit pump lever several times. Read opening pressure (Fig. 2-35) and inspect spray pattern. Compare readings with Specification Data. Important:At 25 - 30 bar below specified opening pressure, check that no fuel will dribble from nozzle.

2-363. Adjust nozzle opening pressure by shims below the spring (adding shims increases pressure and vice versa). Shims of the following thicknesses are available: 1.0; 1.05; 1.1; 1.15; etc. up to 1.95 mm.Fig. 2-36 Note for Refitment:By adding shims the pressure will be increased; by removing them the pressure will be decreased.

2-37For FL 912W, adjust release pressure by means of set-screw. By turning in screw, release pressure is increased; by turning it out, pressure is decreased.Fig. 2-37

2-384. Repeat test and recheck spray pattern. The jet(s) should be solid without surrounding mist. Fig. 2-38

2-39FL 912/W: one jet onlyFig. 2-395. Check that there is no after-dribble.6. If nozzle works unsatisfactorily, replace.Testing The Injection Pump (by special outfit)

The test is confined to making sure that the delivery valves and pump elements are free from leaks. The fuel feed pump intake is connected to the fuel tank or a receptacle containing filtered fuel. Proper fuel delivery is a prerequisite.

2-401. Disconnect injection line(s) on the fuel-injection pump. Evacuate the air from the fuel injection pump. Connect the tester to the pump element to be checked.Fig. 2-40

2-412. Open the second connection of the tester and evacuate the air. When the escaping fuel is free from bubbles, close the second connection.Fig. 2-41 The manual operation of the fuel-injection pump elements differs from one type of engine to another.F2L: Rotate the crankshaft until the air is evacuated or until the pressure has built up.

2-42As from 3 cylinder engine: Lower the tappet of the element to be checked by turning the crankshaft and then pump with a lever.Fig. 2-423. To check a pressure relief valve, generate a pressure of 150 bar. The indicator of the pressure gauge may not drop back more than 10 bar during a minute.

2-434. Generate a pressure peak of 350 bar. This must be clearly indicated by