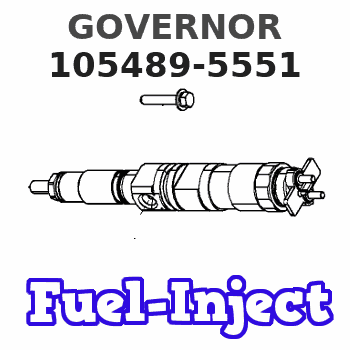

Information governor

BOSCH

9 420 610 560

9420610560

ZEXEL

105489-5551

1054895551

NISSAN-DIESEL

1910197708

1910197708

Rating:

Scheme ###:

| 1. | [1] | 154004-7020 | GOVERNOR HOUSING |

| 9. | [1] | 154350-6000 | PLATE |

| 10. | [4] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 11. | [4] | 020106-1840 | BLEEDER SCREW M6P1L18 |

| 12. | [1] | 154010-7200 | BLEEDER SCREW M8P1.25L62 |

| 13. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 14. | [1] | 154011-0100 | HEXAGON NUT |

| 14B. | [1] | 154011-2300 | UNION NUT |

| 15. | [2] | 139608-0400 | PACKING RING |

| 15. | [2] | 139608-0400 | PACKING RING |

| 16. | [1] | 155004-5000 | LEVER SHAFT |

| 17. | [1] | 154419-2020 | CONTROL LEVER |

| 18. | [1] | 155003-2101 | CONTROL LEVER |

| 19. | [1] | 155006-0700 | BLEEDER SCREW |

| 20. | [1] | 139308-0900 | PLAIN WASHER D16&8T1 |

| 20B. | [1] | 139308-1000 | PLAIN WASHER D16&8T1.5 |

| 22. | [1] | 029310-8050 | SHIM D13.5&8T0.5 |

| 23. | [1] | 025520-1210 | SPLIT PIN |

| 24. | [1] | 154206-2000 | BUSHING |

| 25. | [1] | 154327-4200 | COILED SPRING |

| 26. | [1] | 154382-8920 | CONTROL LEVER |

| 27. | [1] | 014110-8440 | LOCKING WASHER |

| 28. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 29. | [1] | 139408-1400 | SHIM |

| 29B. | [0] | 139408-1400 | SHIM |

| 29C. | [0] | 139408-1500 | SHIM |

| 30. | [1] | 016010-0740 | LOCKING WASHER |

| 35. | [1] | 154516-4820 | GOVERNOR COVER |

| 35/1. | [1] | 154516-4800 | GOVERNOR COVER |

| 35/2. | [1] | 154321-2900 | BUSHING |

| 35/3. | [1] | 139610-1100 | PACKING RING |

| 38. | [1] | 154031-3401 | FLAT-HEAD SCREW |

| 39. | [1] | 013131-0010 | UNION NUT |

| 47. | [2] | 154036-1900 | CAPSULE |

| 47. | [2] | 154036-1900 | CAPSULE |

| 48. | [1] | 154012-4800 | BLEEDER SCREW M10P1.25L51 |

| 48B. | [1] | 154012-4900 | BLEEDER SCREW M10P1.25L47 |

| 49. | [1] | 154011-2200 | UNION NUT |

| 50. | [1] | 155615-1900 | BLEEDER SCREW |

| 51. | [5] | 020106-4540 | BLEEDER SCREW M6P1.0L45 |

| 52. | [2] | 029010-6850 | BLEEDER SCREW |

| 53. | [1] | 154010-3100 | BLEEDER SCREW |

| 54. | [2] | 014110-6440 | LOCKING WASHER |

| 65. | [1] | 155404-3400 | CAP |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154064-2620 | COVER |

| 82. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 83. | [1] | 029020-6210 | BLEEDER SCREW |

| 84. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 86. | [1] | 029020-6210 | BLEEDER SCREW |

| 100. | [1] | 154100-9220 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 139212-0000 | UNION NUT |

| 117. | [1] | 154123-3120 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-8300 | GOVERNOR SPRING |

| 132. | [1] | 154154-0200 | COILED SPRING |

| 140. | [1] | 154189-2220 | HEADLESS SCREW |

| 141. | [1] | 139218-0100 | UNION NUT |

| 142. | [1] | 154242-3020 | HEADLESS SCREW |

| 143. | [1] | 154242-5400 | UNION NUT |

| 144. | [1] | 026516-2040 | GASKET D19.9&16.2T1 |

| 145. | [1] | 154159-1800 | CAP NUT |

| 146. | [1] | 029331-6130 | GASKET |

| 150. | [1] | 154200-5801 | SWIVELLING LEVER |

| 151. | [1] | 154200-5501 | BUSHING |

| 152. | [2] | 139700-0000 | O-RING |

| 152. | [2] | 139700-0000 | O-RING |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 154. | [1] | 139610-0101 | PACKING RING |

| 155. | [1] | 139411-0100 | SHIM D22.0&12.0T0.40 |

| 156. | [0] | 139411-0200 | SHIM D18.0&12.0T0.10 |

| 156B. | [0] | 139411-0300 | SHIM D18.0&12.0T0.20 |

| 156C. | [0] | 139411-0400 | SHIM D18.0&12.0T0.30 |

| 157. | [1] | 154204-3500 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2300 | BUSHING |

| 161. | [0] | 154206-2400 | PLAIN WASHER D20.5&12.2T1 |

| 162. | [1] | 029331-6050 | GASKET |

| 163. | [1] | 154401-4700 | BLEEDER SCREW |

| 164. | [1] | 154243-0820 | CONTROL LEVER |

| 165. | [1] | 154327-6100 | COILED SPRING |

| 166. | [1] | 029310-8320 | SHIM D16.5&8T0.2 |

| 167. | [1] | 154356-3600 | LOCKING WASHER |

| 170. | [1] | 154217-9620 | FORK LEVER |

| 173. | [1] | 016010-0540 | LOCKING WASHER |

| 174. | [1] | 154234-8720 | STRAP |

| 175. | [1] | 154232-2820 | CONNECTOR |

| 176. | [1] | 159231-4900 | BEARING PIN |

| 177. | [1] | 155402-3800 | SAFETY PIN |

| 178. | [1] | 029310-5170 | SHIM D8&5.3T0.5 |

| 179. | [1] | 154238-0201 | BEARING PIN |

| 180. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154239-1820 | TENSIONING LEVER |

| 182. | [1] | 154237-1200 | BEARING PIN |

| 183. | [2] | 154237-1300 | BUSHING |

| 190. | [1] | 154360-2700 | CONTROL LEVER |

| 191. | [1] | 154340-1920 | CONTROL LEVER |

| 192. | [1] | 020006-1670 | BLEEDER SCREW M6P1L16 7T |

| 193. | [1] | 154369-7320 | CONTROL LEVER |

| 194. | [2] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

| 195. | [2] | 154332-6600 | COILED SPRING |

| 196. | [2] | 154156-3000 | TUBE |

| 203/1. | [0] | 139410-0200 | SHIM D32&10.2T0.1 |

| 203/1. | [0] | 139410-0300 | SHIM D32&10.2T0.3 |

| 203/1. | [0] | 139410-0400 | SHIM D32&10.2T0.5 |

| 203/1. | [0] | 139410-0500 | SHIM D32&10.2T0.9 |

| 205. | [1] | 154324-2900 | LEVER SHAFT |

| 207. | [1] | 154326-0300 | CONTROL LEVER |

| 211. | [1] | 016010-0840 | LOCKING WASHER |

| 220. | [1] | 154050-9520 | HEADLESS SCREW |

| 221. | [1] | 029201-2130 | UNION NUT M12P1.0H6 |

| 222. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 223. | [1] | 154159-1200 | CAP NUT |

| 235. | [1] | 029621-7010 | PACKING RING |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0200 | GASKET |

| 238. | [1] | 139700-0100 | O-RING |

| 248. | [1] | 154373-9620 | BRACKET |

| 249. | [1] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

| 250. | [1] | 154410-4620 | SOLENOID |

| 251. | [1] | 154419-2500 | SEAL RING |

| 253. | [1] | 029320-5020 | LOCKING WASHER |

| 254. | [1] | 010535-1040 | FLAT-HEAD SCREW M5P0.8L10 |

| 255. | [1] | 154372-6220 | BRACKET |

| 256. | [2] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

| 257. | [4] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 260. | [1] | 020118-1640 | BLEEDER SCREW |

| 331. | [1] | 154188-3520 | HEADLESS SCREW |

| 332. | [1] | 139218-0500 | UNION NUT |

| 335. | [1] | 154352-2600 | CAPSULE |

| 336. | [1] | 029331-6030 | GASKET |

| 351. | [1] | 139812-0100 | EYE BOLT |

| 355. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 356. | [1] | 029730-6030 | EYE BOLT |

| 357. | [1] | 155012-1200 | ADAPTOR |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105489-5551

1910197708 NISSAN-DIESEL

GOVERNOR

K 14JN MECHANICAL GOVERNOR GOV RFD GOV

K 14JN MECHANICAL GOVERNOR GOV RFD GOV

Information:

Requirements For The ECM

The Electronic Control Module (ECM) for the Diesel Particulate Filter Monitor System is powered by either a +12 VDC or +24 VDC nominal battery. Refer to Table 1 for the limits for the voltage for the ECM. Refer to Illustration There is one 5 VDC +/-0.25 VDC at 500 mA auxiliary Power Supply on the ECM, routed to the machine pin group. A single return pin is used for this power supply. An "AD" channel monitors this power supply. The ECM internal power supply will provide +5 VDC for external sensor use. Refer to Illustration 1.

Illustration 1 g01340837

Illustration 2 displays mounting the Diesel Particulate Filter Monitor System to the ECM.

Illustration 2 g01340267

Table 1

Power Supply Requirements

Requirements for 12 VDC or 24 VDC system Value Notes

Operating Minimum Voltage +9V Minimum continuous operating voltage without damage to the ECM

Operating Minimum Voltage +32V Maximum continuous operating voltage without damage to the ECM

Overvoltage Maximum (two minutes continuous) +80V At 25 °C (77 °F)

Reverse Voltage (one hours) -32V

85 °C (185 °F)

power up voltage for the ECM +9V Minimum voltage for the ECM in order to run internally. Operating the engine at this voltage will cause damage to the ECM.

Cranking Voltage

Maximum current draw with key switch off 10mA

Maximum current draw with 0 engine speed and no loads being driven 500mA

Maximum continuous operating current draw 10A This is highly dependent upon the number and type of loads driven by the ECM.

Recommended Battery Fuse size 15A Programming For The ECM

The ECM is flash programmed via the Customer Data Link (CDL) with the service tool.Key Switch For The ECM

The ECM Key Switch provides the ability to shut down the ECM via a low current switch. The ECM Key Switch also increases the life of the batteries by shutting the ECM off. The Key Switch also allows operators to remotely power off the ECM. The Key Switch controls when the ECM powers up. With the Key Switch "OFF", the ECM current draw will not exceed 10mA.Connector For The ECM

The ECM uses a 70 pin connector to connect to the OEM vehicle wiring harness. The ECM Connector Screw torque should be 6 1 N m (4 0.7 lb ft)Connector Wire Gauge Size For The ECM

The battery positive and negative connections must be made with 14 gauge SAE J1128 type GXL wire for the Deutsch stamped and formed terminal or the Deutsch solid terminal. All other connections may be16 gauge or 18 gauge SAE J1128 type SXL or 14, 16 or 18 gauge SAE J1128 type GXL (or equivalent wire).For most components on the engine an 18 gauge wire has sufficient current capacity, however, many applications will benefit from the increased reliability and durability of 16 gauge

The Electronic Control Module (ECM) for the Diesel Particulate Filter Monitor System is powered by either a +12 VDC or +24 VDC nominal battery. Refer to Table 1 for the limits for the voltage for the ECM. Refer to Illustration There is one 5 VDC +/-0.25 VDC at 500 mA auxiliary Power Supply on the ECM, routed to the machine pin group. A single return pin is used for this power supply. An "AD" channel monitors this power supply. The ECM internal power supply will provide +5 VDC for external sensor use. Refer to Illustration 1.

Illustration 1 g01340837

Illustration 2 displays mounting the Diesel Particulate Filter Monitor System to the ECM.

Illustration 2 g01340267

Table 1

Power Supply Requirements

Requirements for 12 VDC or 24 VDC system Value Notes

Operating Minimum Voltage +9V Minimum continuous operating voltage without damage to the ECM

Operating Minimum Voltage +32V Maximum continuous operating voltage without damage to the ECM

Overvoltage Maximum (two minutes continuous) +80V At 25 °C (77 °F)

Reverse Voltage (one hours) -32V

85 °C (185 °F)

power up voltage for the ECM +9V Minimum voltage for the ECM in order to run internally. Operating the engine at this voltage will cause damage to the ECM.

Cranking Voltage

Maximum current draw with key switch off 10mA

Maximum current draw with 0 engine speed and no loads being driven 500mA

Maximum continuous operating current draw 10A This is highly dependent upon the number and type of loads driven by the ECM.

Recommended Battery Fuse size 15A Programming For The ECM

The ECM is flash programmed via the Customer Data Link (CDL) with the service tool.Key Switch For The ECM

The ECM Key Switch provides the ability to shut down the ECM via a low current switch. The ECM Key Switch also increases the life of the batteries by shutting the ECM off. The Key Switch also allows operators to remotely power off the ECM. The Key Switch controls when the ECM powers up. With the Key Switch "OFF", the ECM current draw will not exceed 10mA.Connector For The ECM

The ECM uses a 70 pin connector to connect to the OEM vehicle wiring harness. The ECM Connector Screw torque should be 6 1 N m (4 0.7 lb ft)Connector Wire Gauge Size For The ECM

The battery positive and negative connections must be made with 14 gauge SAE J1128 type GXL wire for the Deutsch stamped and formed terminal or the Deutsch solid terminal. All other connections may be16 gauge or 18 gauge SAE J1128 type SXL or 14, 16 or 18 gauge SAE J1128 type GXL (or equivalent wire).For most components on the engine an 18 gauge wire has sufficient current capacity, however, many applications will benefit from the increased reliability and durability of 16 gauge