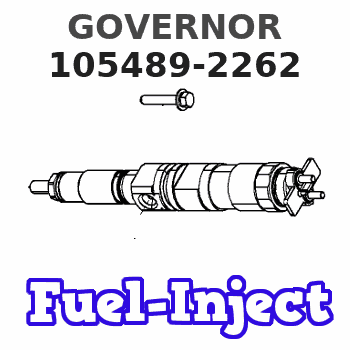

Information governor

BOSCH

9 420 612 129

9420612129

ZEXEL

105489-2262

1054892262

HINO

223005161A

223005161a

Rating:

Scheme ###:

| 1. | [1] | 154004-6420 | GOVERNOR HOUSING |

| 9. | [1] | 154350-6000 | PLATE |

| 10. | [4] | 139006-4100 | BLEEDER SCREW |

| 11. | [4] | 139006-5800 | BLEEDER SCREW |

| 12. | [1] | 154010-7500 | BLEEDER SCREW M8P1.25L50 |

| 12B. | [1] | 154010-7400 | BLEEDER SCREW M8P1.25L55 |

| 13. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 14. | [1] | 154011-0100 | HEXAGON NUT |

| 14B. | [1] | 154011-2300 | UNION NUT |

| 15. | [2] | 029620-8050 | PACKING RING |

| 15. | [2] | 029620-8050 | PACKING RING |

| 16. | [1] | 155004-3600 | LEVER SHAFT |

| 18. | [1] | 155003-3400 | CONTROL LEVER |

| 19. | [1] | 155006-0500 | BLEEDER SCREW |

| 20. | [1] | 139308-1500 | PLAIN WASHER D18&8T1.0 |

| 20B. | [1] | 139308-1600 | PLAIN WASHER D18&8T1.5 |

| 22B. | [0] | 029310-8050 | SHIM D13.5&8T0.5 |

| 23. | [1] | 154373-2200 | SAFETY PIN |

| 24. | [1] | 154206-2000 | BUSHING |

| 25. | [1] | 154327-4400 | COILED SPRING |

| 26. | [1] | 154380-2700 | CONTROL LEVER |

| 27. | [1] | 014110-8440 | LOCKING WASHER |

| 28. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 35. | [1] | 154515-4020 | GOVERNOR COVER |

| 35/2. | [1] | 154321-2000 | BUSHING |

| 35/3. | [1] | 029621-0080 | PACKING RING |

| 38. | [1] | 154031-3401 | FLAT-HEAD SCREW |

| 39. | [1] | 029201-0160 | UNION NUT |

| 47. | [2] | 154036-1800 | CAPSULE |

| 47. | [2] | 154036-1800 | CAPSULE |

| 48. | [1] | 154010-6000 | BLEEDER SCREW M10P1.25L55 |

| 48B. | [1] | 154010-5600 | BLEEDER SCREW M10P1.25L60 |

| 49. | [1] | 154011-2200 | UNION NUT |

| 50. | [1] | 155615-2300 | FLAT-HEAD SCREW |

| 51. | [5] | 020106-4540 | BLEEDER SCREW M6P1.0L45 |

| 52. | [2] | 029010-6850 | BLEEDER SCREW |

| 53. | [1] | 154010-1100 | FLAT-HEAD SCREW |

| 54. | [2] | 014110-6440 | LOCKING WASHER |

| 65. | [1] | 154610-3020 | RACK SENSOR ASSY |

| 65/1. | [1] | 479743-8920 | RACK SENSOR ASSY |

| 65/2. | [1] | 154614-4800 | JOINT CONNECTION |

| 65/3. | [1] | 154614-2900 | BLOCK |

| 65/4. | [1] | 010234-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 65/5. | [1] | 014110-4440 | LOCKING WASHER |

| 65/6. | [1] | 026524-3040 | GASKET |

| 65/7. | [1] | 029310-6280 | SHIM D11.5&6.4T1.50 |

| 65/8. | [1] | 154614-1900 | UNION NUT |

| 65/9. | [1] | 154614-3300 | BEARING PIN |

| 70. | [1] | 154055-0520 | HEADLESS SCREW |

| 80. | [1] | 154063-9100 | COVER |

| 82. | [1] | 029020-6210 | BLEEDER SCREW |

| 83. | [1] | 029020-6240 | BLEEDER SCREW |

| 84. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 86. | [1] | 020006-1840 | BLEEDER SCREW M6P1L18 |

| 100. | [1] | 154100-9320 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 139212-0000 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-8600 | GOVERNOR SPRING |

| 132. | [1] | 154154-0701 | COILED SPRING |

| 140. | [1] | 154183-1820 | HEADLESS SCREW |

| 141. | [1] | 139218-0100 | UNION NUT |

| 150. | [1] | 154200-5601 | SWIVELLING LEVER |

| 151. | [1] | 154200-5501 | BUSHING |

| 152. | [2] | 139700-0000 | O-RING |

| 152. | [2] | 139700-0000 | O-RING |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 154. | [1] | 139610-0101 | PACKING RING |

| 155. | [1] | 139411-0100 | SHIM D22.0&12.0T0.40 |

| 156. | [0] | 139411-0200 | SHIM D18.0&12.0T0.10 |

| 156B. | [0] | 139411-0300 | SHIM D18.0&12.0T0.20 |

| 156C. | [0] | 139411-0400 | SHIM D18.0&12.0T0.30 |

| 157. | [1] | 154204-3500 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 170. | [1] | 154217-7220 | FORK LEVER |

| 173. | [1] | 016010-0540 | LOCKING WASHER |

| 174. | [1] | 154235-0820 | STRAP |

| 175. | [1] | 154232-1821 | CONNECTOR |

| 178. | [1] | 029310-5170 | SHIM D8&5.3T0.5 |

| 179. | [1] | 154238-0201 | BEARING PIN |

| 180. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-5620 | TENSIONING LEVER |

| 182. | [1] | 154237-1200 | BEARING PIN |

| 183. | [2] | 154237-1300 | BUSHING |

| 190. | [1] | 154360-2700 | CONTROL LEVER |

| 191. | [1] | 154340-4520 | CONTROL LEVER |

| 192. | [1] | 020006-1670 | BLEEDER SCREW M6P1L16 7T |

| 193. | [1] | 154385-0220 | CONTROL LEVER |

| 194. | [2] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

| 195. | [2] | 154314-9900 | COILED SPRING |

| 196. | [2] | 154156-1700 | TUBE |

| 203/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 203/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 203/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 203/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 203/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 203/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 203/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 203/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 203/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 203/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 203/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 205. | [1] | 154324-3400 | LEVER SHAFT |

| 207. | [1] | 154326-0300 | CONTROL LEVER |

| 211. | [1] | 016010-0840 | LOCKING WASHER |

| 220. | [1] | 154050-6820 | HEADLESS SCREW |

| 221. | [1] | 029201-2140 | UNION NUT |

| 222. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 223. | [1] | 154159-1200 | CAP NUT |

| 235. | [1] | 155412-5300 | IMPELLER WHEEL |

| 236. | [1] | 154413-2900 | GASKET |

| 237. | [1] | 154390-0200 | GASKET |

| 238. | [1] | 139700-0100 | O-RING |

| 250. | [1] | 154063-9800 | COVER |

| 251. | [1] | 154358-2500 | SEAL RING |

| 252. | [4] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 253. | [1] | 029320-5020 | LOCKING WASHER |

| 254. | [1] | 010535-1040 | FLAT-HEAD SCREW M5P0.8L10 |

| 255. | [1] | 154370-6220 | BRACKET |

| 331. | [1] | 154179-5920 | HEADLESS SCREW |

| 332. | [1] | 139218-0500 | UNION NUT |

| 335. | [1] | 154352-2600 | CAPSULE |

| 336. | [1] | 029331-6030 | GASKET |

| 340. | [1] | 154372-7820 | BRACKET |

| 341. | [2] | 014110-8440 | LOCKING WASHER |

| 342. | [2] | 010038-1840 | BLEEDER SCREW M8P1.25L18 |

| 350. | [1] | 154372-9500 | BRACKET |

| 351. | [2] | 010010-1240 | BLEEDER SCREW M10P1.5L12 4T |

| 352. | [2] | 014111-0440 | LOCKING WASHER |

| 835S. | [1] | 154062-1700 | CAP D20L32 |

| 836S. | [1] | 154062-1800 | CAP D20L27 |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Supplemental Coolant Additive (SCA)

Supplemental cooling system additive contains alkali. To prevent personal injury, do not drink, avoid contact with the skin and eyes.

The cooling system MUST contain supplemental coolant additive (SCA) for proper engine protection, regardless of antifreeze concentration.

DO NOT mix Caterpillar SCA or coolant additive elements with another manufacturer's products: select a cooling system treatment and use it exclusively.

SCA is necessary for proper conventional coolant maintenance. Most coolants DO NOT contain sufficient SCA for diesel engine application.

Do not exceed the recommended six percent SCA concentration. Excessive SCA concentration can form deposits on the higher temperature surfaces of the cooling system, reducing the engine's heat transfer characteristics. Reduced heat transfer could cause cracking of the cylinder head and other high temperature components. Excessive SCA concentration could also result in radiator tube blockage, overheating, and/or accelerated water pump seal wear. Never use both liquid SCA and the spin-on element (if equipped) at the same time. The use of those additives together could result in SCA concentration exceeding the recommended six percent maximum.

Use liquid SCA or a SCA element (if equipped) to maintain a three to six percent SCA concentration in the coolant. Caterpillar Test Kits check for concentration of nitrites in the coolant solution. Some manufacturers' SCA are phosphate based. Caterpillar Test Kits provide inaccurate results with phosphate based SCA. Commercial SCA products must contain silicates and a minimum of 70 grams per 3.8 L (1 US gal) (1200 ppm) nitrites. If another manufacturer's SCA is used, use that manufacturer's test kit. Follow the manufacturer's recommendations for cooling system treatment and test evaluation.Test the coolant periodically to monitor SCA levels. Use the 4C9301 Test Kit to check for Caterpillar SCA concentration. The Kit also provides cooling system maintenance recommendations. This kit is specifically for use with Caterpillar SCA's. The 8T5296 Test Kit can also to check for Caterpillar SCA concentration.The following charts lists the part numbers and quantities of SCA (liquid and solid) available from your Caterpillar dealer. Follow the instructions on the label. Permitted-Water/SCA Coolant

Never use water alone without SCA or inhibited coolant. Water alone is corrosive at engine operating temperatures.

A mixture of water and SCA does not protect against freezing or boiling.

A coolant mixture of water and SCA will cool and provide some protection to engine components, but it will NOT provide normal engine service life.

Caterpillar's recommendation for proper coolant is a minimum concentration of 30 percent glycol and 70 percent Acceptable water and SCA (3 percent of the total mixture). This recommendation will maintain cooling system corrosion protection.

In applications where freeze protection is not required, or where antifreeze is not available, a coolant mixture of Acceptable water and SCA can be used. A Water/SCA system should maintain a six to eight percent SCA concentration. DO NOT exceed eight percent maximum SCA concentration. SCA concentration levels must be monitored.The 8T5296 Test Kit can be used to evaluate the SCA concentration in Water/SCA coolant, with the following modifications to label instruction Step 3 and Step 5.3. Add tap

Supplemental cooling system additive contains alkali. To prevent personal injury, do not drink, avoid contact with the skin and eyes.

The cooling system MUST contain supplemental coolant additive (SCA) for proper engine protection, regardless of antifreeze concentration.

DO NOT mix Caterpillar SCA or coolant additive elements with another manufacturer's products: select a cooling system treatment and use it exclusively.

SCA is necessary for proper conventional coolant maintenance. Most coolants DO NOT contain sufficient SCA for diesel engine application.

Do not exceed the recommended six percent SCA concentration. Excessive SCA concentration can form deposits on the higher temperature surfaces of the cooling system, reducing the engine's heat transfer characteristics. Reduced heat transfer could cause cracking of the cylinder head and other high temperature components. Excessive SCA concentration could also result in radiator tube blockage, overheating, and/or accelerated water pump seal wear. Never use both liquid SCA and the spin-on element (if equipped) at the same time. The use of those additives together could result in SCA concentration exceeding the recommended six percent maximum.

Use liquid SCA or a SCA element (if equipped) to maintain a three to six percent SCA concentration in the coolant. Caterpillar Test Kits check for concentration of nitrites in the coolant solution. Some manufacturers' SCA are phosphate based. Caterpillar Test Kits provide inaccurate results with phosphate based SCA. Commercial SCA products must contain silicates and a minimum of 70 grams per 3.8 L (1 US gal) (1200 ppm) nitrites. If another manufacturer's SCA is used, use that manufacturer's test kit. Follow the manufacturer's recommendations for cooling system treatment and test evaluation.Test the coolant periodically to monitor SCA levels. Use the 4C9301 Test Kit to check for Caterpillar SCA concentration. The Kit also provides cooling system maintenance recommendations. This kit is specifically for use with Caterpillar SCA's. The 8T5296 Test Kit can also to check for Caterpillar SCA concentration.The following charts lists the part numbers and quantities of SCA (liquid and solid) available from your Caterpillar dealer. Follow the instructions on the label. Permitted-Water/SCA Coolant

Never use water alone without SCA or inhibited coolant. Water alone is corrosive at engine operating temperatures.

A mixture of water and SCA does not protect against freezing or boiling.

A coolant mixture of water and SCA will cool and provide some protection to engine components, but it will NOT provide normal engine service life.

Caterpillar's recommendation for proper coolant is a minimum concentration of 30 percent glycol and 70 percent Acceptable water and SCA (3 percent of the total mixture). This recommendation will maintain cooling system corrosion protection.

In applications where freeze protection is not required, or where antifreeze is not available, a coolant mixture of Acceptable water and SCA can be used. A Water/SCA system should maintain a six to eight percent SCA concentration. DO NOT exceed eight percent maximum SCA concentration. SCA concentration levels must be monitored.The 8T5296 Test Kit can be used to evaluate the SCA concentration in Water/SCA coolant, with the following modifications to label instruction Step 3 and Step 5.3. Add tap