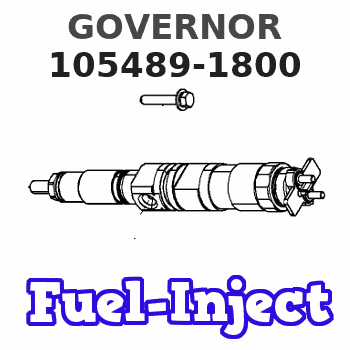

Information governor

BOSCH

F 019 Z3E 565

f019z3e565

ZEXEL

105489-1800

1054891800

Rating:

Scheme ###:

| 1. | [1] | 154004-6320 | GOVERNOR HOUSING |

| 2. | [1] | 154012-4620 | BLEEDER SCREW |

| 3. | [1] | 014110-8440 | LOCKING WASHER |

| 9. | [1] | 154353-5601 | PLATE |

| 10. | [4] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 11. | [4] | 020106-1840 | BLEEDER SCREW M6P1L18 |

| 12. | [1] | 154010-8100 | BLEEDER SCREW M8P1.25L65 |

| 13. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 14. | [1] | 154011-0100 | HEXAGON NUT |

| 14B. | [1] | 154011-2300 | UNION NUT |

| 15. | [1] | 139608-0300 | PACKING RING |

| 15B. | [1] | 026516-2040 | GASKET D19.9&16.2T1 |

| 15C. | [1] | 154372-3900 | CAPSULE |

| 16. | [1] | 155003-3320 | LEVER SHAFT |

| 18. | [1] | 155003-2101 | CONTROL LEVER |

| 19. | [1] | 155006-0700 | BLEEDER SCREW |

| 20. | [1] | 139408-0700 | SHIM |

| 22. | [0] | 029310-8040 | SHIM D13.5&8T0.2 |

| 22. | [7] | 139408-1400 | SHIM |

| 22B. | [0] | 029310-8050 | SHIM D13.5&8T0.5 |

| 22B. | [7] | 139408-1500 | SHIM |

| 23. | [1] | 025520-1210 | SPLIT PIN |

| 24. | [1] | 154206-2000 | BUSHING |

| 25. | [1] | 154327-8600 | COILED SPRING |

| 26. | [1] | 154380-0600 | CONTROL LEVER |

| 27. | [1] | 014110-8440 | LOCKING WASHER |

| 28. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 29. | [1] | 139408-1400 | SHIM |

| 29B. | [0] | 139408-1400 | SHIM |

| 29C. | [0] | 139408-1500 | SHIM |

| 35. | [1] | 154515-1220 | GOVERNOR COVER |

| 35/2. | [1] | 154321-2000 | BUSHING |

| 35/3. | [1] | 139610-0600 | PACKING RING |

| 35/5. | [1] | 154242-1800 | GUIDE SLEEVE |

| 38. | [1] | 154031-3401 | FLAT-HEAD SCREW |

| 39. | [1] | 029201-0160 | UNION NUT |

| 47. | [2] | 154036-1800 | CAPSULE |

| 47. | [2] | 154036-1800 | CAPSULE |

| 48. | [1] | 154010-6000 | BLEEDER SCREW M10P1.25L55 |

| 49. | [1] | 154011-2200 | UNION NUT |

| 50. | [1] | 155615-2300 | FLAT-HEAD SCREW |

| 51. | [5] | 020106-4540 | BLEEDER SCREW M6P1.0L45 |

| 52. | [2] | 029010-6850 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 54. | [2] | 014110-6440 | LOCKING WASHER |

| 65. | [1] | 153043-7720 | STOPPING DEVICE |

| 80. | [1] | 154063-5320 | COVER |

| 82. | [1] | 029020-6210 | BLEEDER SCREW |

| 83. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 84. | [1] | 029020-6210 | BLEEDER SCREW |

| 86. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154100-9220 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 139212-0000 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-8400 | GOVERNOR SPRING |

| 132. | [1] | 154154-0701 | COILED SPRING |

| 140. | [1] | 154183-0920 | HEADLESS SCREW |

| 141. | [1] | 139218-0100 | UNION NUT |

| 142. | [1] | 154242-1500 | STOP PIN |

| 143. | [1] | 154242-2800 | COILED SPRING |

| 144. | [1] | 154242-1600 | GUIDE SLEEVE |

| 145. | [2] | 139522-0000 | GASKET |

| 146. | [1] | 139222-0100 | UNION NUT |

| 147. | [1] | 023020-8040 | UNION NUT M8P1H5 |

| 148. | [1] | 154159-1400 | CAP NUT |

| 150. | [1] | 154200-5701 | SWIVELLING LEVER |

| 151. | [1] | 154200-5501 | BUSHING |

| 152. | [2] | 139719-0000 | O-RING |

| 152. | [2] | 139719-0000 | O-RING |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 154. | [1] | 139612-0000 | PACKING RING |

| 155. | [1] | 139411-0100 | SHIM D22.0&12.0T0.40 |

| 156. | [0] | 139411-0200 | SHIM D18.0&12.0T0.10 |

| 156B. | [0] | 139411-0300 | SHIM D18.0&12.0T0.20 |

| 156C. | [0] | 139411-0400 | SHIM D18.0&12.0T0.30 |

| 157. | [1] | 154204-3500 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2300 | BUSHING |

| 161. | [0] | 154206-2400 | PLAIN WASHER D20.5&12.2T1 |

| 162. | [1] | 139516-0100 | GASKET |

| 163. | [1] | 154401-3201 | BLEEDER SCREW |

| 164. | [1] | 154243-0720 | CONTROL LEVER |

| 165. | [1] | 154327-6000 | COILED SPRING |

| 166. | [1] | 029310-8320 | SHIM D16.5&8T0.2 |

| 167. | [1] | 154356-3600 | LOCKING WASHER |

| 170. | [1] | 154217-5020 | FORK LEVER |

| 173. | [1] | 016010-0540 | LOCKING WASHER |

| 174. | [1] | 154234-0520 | STRAP |

| 175. | [1] | 154232-1821 | CONNECTOR |

| 176. | [1] | 159231-4900 | BEARING PIN |

| 177. | [1] | 155402-3800 | SAFETY PIN |

| 178. | [1] | 029310-5170 | SHIM D8&5.3T0.5 |

| 179. | [1] | 154238-0201 | BEARING PIN |

| 180. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-7521 | TENSIONING LEVER |

| 182. | [1] | 154237-1200 | BEARING PIN |

| 183. | [2] | 154237-1300 | BUSHING |

| 183. | [2] | 154237-1300 | BUSHING |

| 187. | [1] | 014110-6440 | LOCKING WASHER |

| 188. | [1] | 154156-1500 | TUBE |

| 189. | [1] | 154357-6320 | BLEEDER SCREW |

| 190. | [1] | 154360-2800 | CONTROL LEVER |

| 191. | [1] | 154340-1920 | CONTROL LEVER |

| 192. | [1] | 154371-8300 | BLEEDER SCREW |

| 193. | [1] | 154369-5120 | CONTROL LEVER |

| 195. | [2] | 154317-1200 | COILED SPRING |

| 196. | [2] | 154156-0600 | TUBE |

| 197/1. | [0] | 029310-8610 | SHIM D10.5&8.5T0.1 |

| 197/1. | [0] | 029310-8620 | SHIM D10.5&8.5T0.15 |

| 197/1. | [0] | 029310-8630 | SHIM D10.5&8.5T0.2 |

| 197/1. | [0] | 029310-8650 | SHIM D10.5&8.5T0.5 |

| 198. | [1] | 014110-8440 | LOCKING WASHER |

| 199. | [1] | 154317-0900 | COILED SPRING |

| 200. | [1] | 016010-0740 | LOCKING WASHER |

| 203/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 203/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 203/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 203/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 203/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 203/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 203/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 203/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 203/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 203/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 203/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 205. | [1] | 154324-4100 | LEVER SHAFT |

| 207. | [1] | 154326-0300 | CONTROL LEVER |

| 211. | [1] | 016010-0840 | LOCKING WASHER |

| 220. | [1] | 154050-6820 | HEADLESS SCREW |

| 221. | [1] | 029201-2140 | UNION NUT |

| 222. | [2] | 139512-0000 | GASKET D17.2&12.2T1.0 |

| 223. | [1] | 154159-1200 | CAP NUT |

| 235. | [1] | 155412-5200 | IMPELLER WHEEL |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0200 | GASKET |

| 238. | [1] | 154390-1400 | GASKET |

| 250. | [1] | 154414-7620 | STARTING FUEL AIDS |

| 250/1. | [1] | 154414-7720 | GOVERNOR HOUSING |

| 250/2. | [3] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 250/3. | [1] | 029020-6210 | BLEEDER SCREW |

| 250/4. | [1] | 154414-5300 | COVER |

| 250/5. | [1] | 154414-5400 | GASKET |

| 250/6. | [4] | 020105-1040 | BLEEDER SCREW M5P0.8L10 |

| 250/7. | [1] | 153141-1600 | BLEEDER SCREW |

| 250/8. | [1] | 029240-6010 | UNION NUT M6P1.0H5* |

| 250/11. | [1] | 154414-8520 | CONTROL LEVER |

| 250/15. | [1] | 139610-0600 | PACKING RING |

| 250/16. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 250/17. | [1] | 154414-5900 | BUSHING |

| 250/18. | [1] | 014110-8440 | LOCKING WASHER |

| 250/19. | [1] | 013010-8040 | UNION NUT M8P0.9H7 |

| 250/20. | [1] | 154414-8100 | COILED SPRING |

| 250/21. | [1] | 154414-8200 | CONTROL LEVER |

| 251. | [1] | 154419-2500 | SEAL RING |

| 253. | [1] | 029320-5020 | LOCKING WASHER |

| 254. | [1] | 010535-1040 | FLAT-HEAD SCREW M5P0.8L10 |

| 331. | [1] | 154179-4520 | HEADLESS SCREW |

| 332. | [1] | 139218-0500 | UNION NUT |

| 335. | [1] | 154352-2600 | CAPSULE |

| 336. | [1] | 139516-0100 | GASKET |

| 350. | [1] | 154359-4200 | CAP |

| 360. | [1] | 010006-2540 | BLEEDER SCREW M6P1L25 4T |

| 361. | [1] | 154357-3100 | BUSHING |

| 835S. | [2] | 154062-1700 | CAP D20L32 |

| 835S. | [2] | 154062-1700 | CAP D20L32 |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Include in #1:

106671-1630

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Lubricant Viscosity Recommendations

The proper SAE grade of oil to select is determined by the minimum outside temperature at which the engine will be started and the maximum outside temperature in which the engine will be operating. This recommendation is to ensure the correct viscosity is used until the next oil change. Engine start-up at lower than specified ambient temperature requires caution. Start-up at very low ambient temperatures may require a jacket water heater, auxiliary oil heaters or other methods to increase the engine crankcase and surrounding temperatures. When operating below -20°C (-4°F) refer to Caterpillar for information.The use of multi-viscosity oils is preferred because of full protection through a wider temperature range. See chart for recommended viscosity and temperature range. To determine if the oil in the crankcase will flow in cold weather, remove the oil dipstick before starting. If the oil will flow off, the oil is fluid enough to circulate properly.Lubricant Viscosity Chart

Refill Capacities

Engine Crankcase Oil Capacity

The crankcase refill capacities reflect the engine crankcase capacity plus on-engine oil filter change. If equipped with an auxiliary oil filter system, consult the oil filter system manufacturer for information.Total Cooling System Capacity

The Total Cooling System capacity will vary, depending on the engine model (3114 or 3116), radiator system size and capacity provided by truck/vehicle manufacturer. In order to properly maintain the cooling system, Total Cooling System capacity must be known. The chart below is left blank and should be filled in by the customer to determine the Total Cooling System Capacity for his engine and application.Add 0.25 liter (0.5 U.S. pint) of Caterpillar liquid supplemental coolant additive (Conditioner) for every 30 liter (8 U.S. gallon) of cooling system capacity to maintain the cooling system at Every 250 Service Hours.

The proper SAE grade of oil to select is determined by the minimum outside temperature at which the engine will be started and the maximum outside temperature in which the engine will be operating. This recommendation is to ensure the correct viscosity is used until the next oil change. Engine start-up at lower than specified ambient temperature requires caution. Start-up at very low ambient temperatures may require a jacket water heater, auxiliary oil heaters or other methods to increase the engine crankcase and surrounding temperatures. When operating below -20°C (-4°F) refer to Caterpillar for information.The use of multi-viscosity oils is preferred because of full protection through a wider temperature range. See chart for recommended viscosity and temperature range. To determine if the oil in the crankcase will flow in cold weather, remove the oil dipstick before starting. If the oil will flow off, the oil is fluid enough to circulate properly.Lubricant Viscosity Chart

Refill Capacities

Engine Crankcase Oil Capacity

The crankcase refill capacities reflect the engine crankcase capacity plus on-engine oil filter change. If equipped with an auxiliary oil filter system, consult the oil filter system manufacturer for information.Total Cooling System Capacity

The Total Cooling System capacity will vary, depending on the engine model (3114 or 3116), radiator system size and capacity provided by truck/vehicle manufacturer. In order to properly maintain the cooling system, Total Cooling System capacity must be known. The chart below is left blank and should be filled in by the customer to determine the Total Cooling System Capacity for his engine and application.Add 0.25 liter (0.5 U.S. pint) of Caterpillar liquid supplemental coolant additive (Conditioner) for every 30 liter (8 U.S. gallon) of cooling system capacity to maintain the cooling system at Every 250 Service Hours.