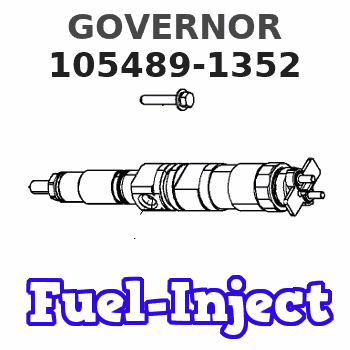

Information governor

BOSCH

9 420 612 610

9420612610

ZEXEL

105489-1352

1054891352

ISUZU

1157700952

1157700952

Rating:

Scheme ###:

| 1. | [1] | 154004-2000 | GOVERNOR HOUSING |

| 4. | [1] | 154364-8820 | CONTROL LEVER |

| 4. | [1] | 154364-8820 | CONTROL LEVER |

| 4/1. | [1] | 154304-6200 | CONTROL LEVER |

| 4/2. | [2] | 154352-2000 | BLEEDER SCREW |

| 4/2. | [2] | 154352-2000 | BLEEDER SCREW |

| 4/3. | [1] | 154364-8800 | CONTROL LEVER |

| 4/4. | [1] | 029311-0230 | SHIM D18&10.3T0.5 |

| 4/5. | [1] | 154321-1500 | BUSHING |

| 4/6. | [1] | 154327-2901 | COILED SPRING |

| 4/7. | [1] | 154322-0100 | CAP |

| 4/8. | [1] | 029311-0220 | SHIM D18&10.3T0.2 |

| 4/9. | [1] | 154324-2700 | LEVER SHAFT |

| 4/10. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 9. | [1] | 154353-5601 | PLATE |

| 10. | [4] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 11. | [4] | 020106-1840 | BLEEDER SCREW M6P1L18 |

| 12. | [1] | 154010-8100 | BLEEDER SCREW M8P1.25L65 |

| 13. | [1] | 029240-6010 | UNION NUT M6P1.0H5* |

| 14. | [1] | 154011-0100 | HEXAGON NUT |

| 14B. | [1] | 154011-2300 | UNION NUT |

| 35. | [1] | 154513-7420 | GOVERNOR COVER |

| 35/2. | [1] | 154321-2000 | BUSHING |

| 35/3. | [1] | 029621-0080 | PACKING RING |

| 35/5. | [1] | 154242-1800 | GUIDE SLEEVE |

| 38. | [1] | 154031-3401 | FLAT-HEAD SCREW |

| 39. | [1] | 029201-0160 | UNION NUT |

| 47. | [2] | 154036-1800 | CAPSULE |

| 47. | [2] | 154036-1800 | CAPSULE |

| 48. | [1] | 154010-7100 | BLEEDER SCREW M10P1.25L47 |

| 48B. | [1] | 154010-7700 | BLEEDER SCREW M10P1.25L51 |

| 49. | [1] | 154011-2200 | UNION NUT |

| 50. | [1] | 155615-2300 | FLAT-HEAD SCREW |

| 51. | [5] | 020106-4540 | BLEEDER SCREW M6P1.0L45 |

| 52. | [2] | 029010-6850 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 54. | [2] | 014110-6440 | LOCKING WASHER |

| 65. | [1] | 153043-5220 | STOPPING DEVICE |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154063-6621 | COVER |

| 82. | [1] | 029020-6240 | BLEEDER SCREW |

| 83. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 84. | [1] | 029020-6240 | BLEEDER SCREW |

| 86. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154100-9220 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 139212-0000 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-8300 | GOVERNOR SPRING |

| 132. | [1] | 154154-0701 | COILED SPRING |

| 140. | [1] | 154183-0920 | HEADLESS SCREW |

| 141. | [1] | 139218-0100 | UNION NUT |

| 142. | [1] | 154242-1500 | STOP PIN |

| 143. | [1] | 154242-4500 | COILED SPRING |

| 144. | [1] | 154242-1600 | GUIDE SLEEVE |

| 145. | [2] | 029332-2030 | GASKET D25.5&22T1 |

| 146. | [1] | 139222-0100 | UNION NUT |

| 147. | [2] | 023020-8040 | UNION NUT M8P1H5 |

| 148. | [1] | 154159-1400 | CAP NUT |

| 150. | [1] | 154200-5701 | SWIVELLING LEVER |

| 151. | [1] | 154200-5501 | BUSHING |

| 152. | [2] | 139700-0000 | O-RING |

| 152. | [2] | 139700-0000 | O-RING |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 154. | [1] | 139610-0101 | PACKING RING |

| 155. | [1] | 139411-0100 | SHIM D22.0&12.0T0.40 |

| 156. | [0] | 139411-0200 | SHIM D18.0&12.0T0.10 |

| 156B. | [0] | 139411-0300 | SHIM D18.0&12.0T0.20 |

| 156C. | [0] | 139411-0400 | SHIM D18.0&12.0T0.30 |

| 157. | [1] | 154204-3500 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2300 | BUSHING |

| 161. | [0] | 154206-2400 | PLAIN WASHER D20.5&12.2T1 |

| 162. | [1] | 029331-6050 | GASKET |

| 163. | [1] | 154401-3201 | BLEEDER SCREW |

| 164. | [1] | 154243-0720 | CONTROL LEVER |

| 165. | [1] | 154327-6000 | COILED SPRING |

| 166. | [1] | 029310-8320 | SHIM D16.5&8T0.2 |

| 167. | [1] | 154356-3600 | LOCKING WASHER |

| 170. | [1] | 154216-8420 | FORK LEVER |

| 173. | [1] | 016010-0540 | LOCKING WASHER |

| 174. | [1] | 154230-8120 | STRAP |

| 179. | [1] | 154238-0201 | BEARING PIN |

| 180. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-7521 | TENSIONING LEVER |

| 182. | [1] | 154237-1200 | BEARING PIN |

| 183. | [2] | 154237-1300 | BUSHING |

| 187. | [1] | 014110-6440 | LOCKING WASHER |

| 188. | [1] | 154156-1500 | TUBE |

| 189. | [1] | 154357-6320 | BLEEDER SCREW |

| 190. | [1] | 154360-2800 | CONTROL LEVER |

| 191. | [1] | 154340-1920 | CONTROL LEVER |

| 192. | [1] | 154371-8300 | BLEEDER SCREW |

| 193. | [1] | 154368-9020 | CONTROL LEVER |

| 195. | [2] | 154317-5300 | COILED SPRING |

| 196. | [2] | 154156-0600 | TUBE |

| 197/1. | [0] | 029310-8610 | SHIM D10.5&8.5T0.1 |

| 197/1. | [0] | 029310-8620 | SHIM D10.5&8.5T0.15 |

| 197/1. | [0] | 029310-8630 | SHIM D10.5&8.5T0.2 |

| 197/1. | [0] | 029310-8650 | SHIM D10.5&8.5T0.5 |

| 198. | [1] | 014110-8440 | LOCKING WASHER |

| 199. | [1] | 154317-2000 | COILED SPRING |

| 200. | [1] | 016010-0740 | LOCKING WASHER |

| 203/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 203/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 203/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 203/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 203/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 203/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 203/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 203/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 203/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 203/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 203/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 205. | [1] | 154324-4100 | LEVER SHAFT |

| 207. | [1] | 154326-0300 | CONTROL LEVER |

| 211. | [1] | 016010-0840 | LOCKING WASHER |

| 220. | [1] | 154050-6820 | HEADLESS SCREW |

| 221. | [1] | 029201-2140 | UNION NUT |

| 222. | [2] | 139512-0000 | GASKET D17.2&12.2T1.0 |

| 223. | [1] | 154159-1200 | CAP NUT |

| 235. | [1] | 155412-5200 | IMPELLER WHEEL |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0200 | GASKET |

| 238. | [1] | 154390-1400 | GASKET |

| 255. | [1] | 154371-8420 | BRACKET |

| 331. | [1] | 154179-3620 | HEADLESS SCREW |

| 332. | [1] | 139218-0500 | UNION NUT |

| 335. | [1] | 154352-2600 | CAPSULE |

| 336. | [1] | 029331-6030 | GASKET |

| 350. | [1] | 154357-5800 | CAP |

| 360. | [1] | 154357-6900 | BEARING PIN |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Include in #1:

106671-1512

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Under the Hood Inspection

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn belts and trash build-up. Remove trash build-up and have repairs made as needed.Perform required Daily maintenance before starting the engine.

Each time any significant quantity of oil (or other fluid) is spilled on or near the engine it should be cleaned up. Accumulated grease and oil on an engine is a fire hazard. Remove this debris with steam cleaning or high pressure water at PM Level 2 or every 6000 hours.Wipe clean all fittings, caps and plugs before servicing.

Starting the Engine

Do not store starting fluid containers in the cab. Failure to do so, could result in an explosion and/or fire and possible personal injury.If equipped with an electrically or fuel ignited manifold heater, DO NOT use ether.If equipped with Flammstart, DO NOT use ether.

Startability will be improved at temperatures below +32°F (0°C) by the use of a starting aid (ether) or use of a cylinder block coolant heater or other means to heat the crankcase oil. This will help alleviate white smoke and misfire during cold weather start-up.Use ether when temperatures are below 32°F (0°C) for cold weather starting purposes only.

When using starting fluid, follow the manufacturer's instructions carefully, use it sparingly and spray it ONLY WHILE CRANKING THE ENGINE. Excessive ether can cause piston and ring damage.Use ether for cold starting purposes only.

If the engine fails to start within 30 seconds, release the starter switch and wait two minutes to allow the starter motor to cool before using it again.Start the engine using the following procedure:1. Place the transmission in NEUTRAL and disengage the flywheel clutch (if equipped) to remove the transmission drag and prevent movement of the truck.Depressing the clutch in cold weather can mean the difference between starting and not starting. Depressing the clutch in warm weather produces faster starts and reduces battery drain.2. Turn the ignition switch to the ON position and push the crank button or turn the ignition switch to the START position.It may be necessary to push down on the throttle to get the fuel rack to move to the "fuel on" position for mechanical fuel system engines.

DO NOT PUSH DOWN OR HOLD THE THROTTLE DOWN while cranking the Electronic engine. The system will automatically provide the correct amount of fuel to start the engine.

3. Crank the engine. If the engine fails to start in 30 seconds, release the starting (ignition) switch and wait two minutes to allow the starter motor to cool before using it again. The Electronic engine may need to crank slightly longer than a mechanically governed engine, because some oil pressure is required for the electronic actuator to move the rack. The CHECK ENGINE/DIAGNOSTIC lamp should be ON while the engine is cranking, but should go OFF after engine oil pressure is achieved.

Do not increase engine speed until the oil pressure gauge indicates normal.

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn belts and trash build-up. Remove trash build-up and have repairs made as needed.Perform required Daily maintenance before starting the engine.

Each time any significant quantity of oil (or other fluid) is spilled on or near the engine it should be cleaned up. Accumulated grease and oil on an engine is a fire hazard. Remove this debris with steam cleaning or high pressure water at PM Level 2 or every 6000 hours.Wipe clean all fittings, caps and plugs before servicing.

Starting the Engine

Do not store starting fluid containers in the cab. Failure to do so, could result in an explosion and/or fire and possible personal injury.If equipped with an electrically or fuel ignited manifold heater, DO NOT use ether.If equipped with Flammstart, DO NOT use ether.

Startability will be improved at temperatures below +32°F (0°C) by the use of a starting aid (ether) or use of a cylinder block coolant heater or other means to heat the crankcase oil. This will help alleviate white smoke and misfire during cold weather start-up.Use ether when temperatures are below 32°F (0°C) for cold weather starting purposes only.

When using starting fluid, follow the manufacturer's instructions carefully, use it sparingly and spray it ONLY WHILE CRANKING THE ENGINE. Excessive ether can cause piston and ring damage.Use ether for cold starting purposes only.

If the engine fails to start within 30 seconds, release the starter switch and wait two minutes to allow the starter motor to cool before using it again.Start the engine using the following procedure:1. Place the transmission in NEUTRAL and disengage the flywheel clutch (if equipped) to remove the transmission drag and prevent movement of the truck.Depressing the clutch in cold weather can mean the difference between starting and not starting. Depressing the clutch in warm weather produces faster starts and reduces battery drain.2. Turn the ignition switch to the ON position and push the crank button or turn the ignition switch to the START position.It may be necessary to push down on the throttle to get the fuel rack to move to the "fuel on" position for mechanical fuel system engines.

DO NOT PUSH DOWN OR HOLD THE THROTTLE DOWN while cranking the Electronic engine. The system will automatically provide the correct amount of fuel to start the engine.

3. Crank the engine. If the engine fails to start in 30 seconds, release the starting (ignition) switch and wait two minutes to allow the starter motor to cool before using it again. The Electronic engine may need to crank slightly longer than a mechanically governed engine, because some oil pressure is required for the electronic actuator to move the rack. The CHECK ENGINE/DIAGNOSTIC lamp should be ON while the engine is cranking, but should go OFF after engine oil pressure is achieved.

Do not increase engine speed until the oil pressure gauge indicates normal.