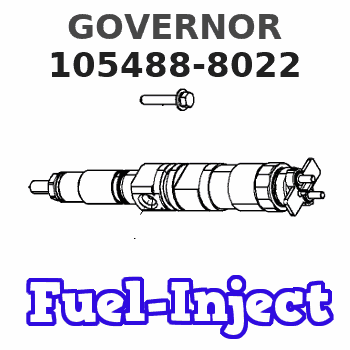

Information governor

BOSCH

F 019 Z2F 419

f019z2f419

ZEXEL

105488-8022

1054888022

ISUZU

1157205050

1157205050

Rating:

Scheme ###:

| 1. | [1] | 154004-2000 | GOVERNOR HOUSING |

| 4. | [1] | 154364-8820 | CONTROL LEVER |

| 4. | [1] | 154364-8820 | CONTROL LEVER |

| 4/1. | [1] | 154304-6200 | CONTROL LEVER |

| 4/2. | [2] | 154352-2000 | BLEEDER SCREW |

| 4/2. | [2] | 154352-2000 | BLEEDER SCREW |

| 4/3. | [1] | 154364-8800 | CONTROL LEVER |

| 4/4. | [1] | 029311-0230 | SHIM D18&10.3T0.5 |

| 4/5. | [1] | 154321-1500 | BUSHING |

| 4/6. | [1] | 154327-2901 | COILED SPRING |

| 4/7. | [1] | 154322-0100 | CAP |

| 4/8. | [1] | 029311-0220 | SHIM D18&10.3T0.2 |

| 4/9. | [1] | 154324-2700 | LEVER SHAFT |

| 4/10. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 9. | [1] | 154353-5601 | PLATE |

| 10. | [4] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 11. | [4] | 020106-1840 | BLEEDER SCREW M6P1L18 |

| 12. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 13. | [1] | 029240-6010 | UNION NUT M6P1.0H5* |

| 14. | [2] | 154011-0100 | HEXAGON NUT |

| 14. | [2] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154513-6820 | COVER |

| 35/2. | [1] | 154321-2000 | BUSHING |

| 35/3. | [1] | 029621-0080 | PACKING RING |

| 38. | [1] | 154031-3401 | FLAT-HEAD SCREW |

| 39. | [1] | 029201-0160 | UNION NUT |

| 47. | [2] | 154036-1800 | CAPSULE |

| 47. | [2] | 154036-1800 | CAPSULE |

| 48. | [1] | 154010-5500 | BLEEDER SCREW M10P1.25L42 |

| 49. | [1] | 154011-2100 | UNION NUT |

| 50. | [1] | 155615-2300 | FLAT-HEAD SCREW |

| 51. | [5] | 020106-4540 | BLEEDER SCREW M6P1.0L45 |

| 52. | [2] | 029010-6850 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 54. | [2] | 014110-6440 | LOCKING WASHER |

| 65. | [1] | 153043-5220 | STOPPING DEVICE |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154063-6620 | COVER |

| 80/2. | [1] | 131423-1700 | CONNECTOR |

| 82. | [1] | 029020-6210 | BLEEDER SCREW |

| 83. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 84. | [1] | 029020-6210 | BLEEDER SCREW |

| 86. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154100-9220 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 139212-0000 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-9000 | GOVERNOR SPRING |

| 132. | [1] | 154154-0701 | COILED SPRING |

| 140. | [1] | 154183-2120 | HEADLESS SCREW |

| 141. | [1] | 139218-0100 | UNION NUT |

| 150. | [1] | 154200-5701 | SWIVELLING LEVER |

| 151. | [1] | 154200-5501 | BUSHING |

| 152. | [2] | 139700-0000 | O-RING |

| 152. | [2] | 139700-0000 | O-RING |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 154. | [1] | 139610-0101 | PACKING RING |

| 155. | [1] | 139411-0100 | SHIM D22.0&12.0T0.40 |

| 156. | [0] | 139411-0200 | SHIM D18.0&12.0T0.10 |

| 156B. | [0] | 139411-0300 | SHIM D18.0&12.0T0.20 |

| 156C. | [0] | 139411-0400 | SHIM D18.0&12.0T0.30 |

| 157. | [1] | 154204-3500 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2300 | BUSHING |

| 161. | [0] | 154206-2400 | PLAIN WASHER D20.5&12.2T1 |

| 170. | [1] | 154216-5220 | FORK LEVER |

| 173. | [1] | 016010-0540 | LOCKING WASHER |

| 174. | [1] | 154230-8120 | STRAP |

| 179. | [1] | 154238-0701 | BEARING PIN |

| 180. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-9220 | TENSIONING LEVER |

| 182. | [1] | 154237-1200 | BEARING PIN |

| 183. | [2] | 154237-1800 | BUSHING |

| 183. | [2] | 154237-1800 | BUSHING |

| 187. | [1] | 014110-6440 | LOCKING WASHER |

| 188. | [1] | 154156-1500 | TUBE |

| 189. | [1] | 154357-6320 | BLEEDER SCREW |

| 190. | [1] | 154360-2800 | CONTROL LEVER |

| 191. | [1] | 154340-1920 | CONTROL LEVER |

| 192. | [1] | 154357-6401 | BLEEDER SCREW |

| 193. | [1] | 154362-0820 | CONTROL LEVER |

| 194. | [2] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

| 197/1. | [0] | 029310-8610 | SHIM D10.5&8.5T0.1 |

| 197/1. | [0] | 029310-8620 | SHIM D10.5&8.5T0.15 |

| 197/1. | [0] | 029310-8630 | SHIM D10.5&8.5T0.2 |

| 197/1. | [0] | 029310-8650 | SHIM D10.5&8.5T0.5 |

| 198. | [1] | 014110-8440 | LOCKING WASHER |

| 199. | [1] | 154317-0900 | COILED SPRING |

| 200. | [1] | 016010-0740 | LOCKING WASHER |

| 203/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 203/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 203/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 203/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 203/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 203/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 203/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 203/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 203/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 203/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 203/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 205. | [1] | 154324-3500 | LEVER SHAFT |

| 207. | [1] | 154326-6522 | CONTROL LEVER |

| 211. | [1] | 016010-0840 | LOCKING WASHER |

| 220. | [1] | 154050-6820 | HEADLESS SCREW |

| 221. | [1] | 029201-2140 | UNION NUT |

| 222. | [2] | 139512-0000 | GASKET D17.2&12.2T1.0 |

| 223. | [1] | 154159-1200 | CAP NUT |

| 235. | [1] | 155412-5200 | IMPELLER WHEEL |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0200 | GASKET |

| 238. | [1] | 154390-1400 | GASKET |

| 331. | [1] | 154179-5020 | HEADLESS SCREW |

| 332. | [1] | 139218-0500 | UNION NUT |

| 335. | [1] | 154352-2600 | CAPSULE |

| 336. | [1] | 029331-6030 | GASKET |

| 350. | [1] | 154357-5800 | CAP |

| 360. | [1] | 154357-6900 | BEARING PIN |

Include in #1:

106691-6944

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Starter Motor

The starter motor is used to turn the engine flywheel fast enough to get the engine to start running.The starter motor has a solenoid. When the start switch is activated, the solenoid will move the starter pinion to engage it with the ring gear on the flywheel of the engine. The starter pinion will engage with the ring gear before the electric contacts in the solenoid close the circuit between the battery and the starter motor. When the circuit between the battery and the starter motor is complete, the pinion will turn the engine flywheel. A clutch gives protection for the starter motor so that the engine cannot turn the starter motor too fast. When the start switch is released, the starter pinion will move away from the ring gear.

Starter Motor Cross Section

(1) Field. (2) Solenoid. (3) Clutch. (4) Pinion. (5) Commutator. (6) Brush assembly. (7) Armature.Other Components

Circuit Breaker

Circuit Breaker Schematic

(1) Reset button. (2) Disc in open position. (3) Contacts. (4) Disc. (5) Battery circuit terminals.The circuit breaker is a switch that opens the battery circuit if the current in the electrical system goes higher than the rating of the circuit breaker.A heat activated metal disc with a contact point makes complete the electric circuit through the circuit breaker. If the current in the electrical system gets too high, it causes the metal disc to get hot. This heat causes a distortion of the metal disc which opens the contacts and breaks the circuit. A circuit breaker that is open can be reset (an adjustment to make the circuit complete again) after it becomes cool. Push the reset button to close the contacts and reset the circuit breaker.Jake Brake

The JAKE BRAKE permits the operator to control the speed of the vehicle on grades, curves, or anytime when speed reduction is necessary, but long applications of the service brakes are not desired. In downhill operation, or any slow down condition, the engine crankshaft is turned by the rear wheels (through the differential, driveshaft, transmission and clutch). To reduce the speed of the vehicle, an application of a braking force can be made to the pistons of the engine.The JAKE BRAKE, when activated, does this through the conversion of the engine from a source of power to an air compressor that absorbs (takes) power. This conversion is made possible by a master to slave piston arrangement, where movement of the rocker arm for the exhaust valve of one cylinder is transferred hydraulically to open the exhaust valve of another cylinder near the top of its normal compression stroke cycle. The compressed cylinder charge is now released into the exhaust manifold.The release of the compressed air pressure to the atmosphere prevents the return of energy to the engine piston on the expansion (power) stroke. The result is an energy loss, since the work done by the compression of the cylinder charge is not returned by the expansion process. This energy loss is taken from the rear wheels, which provides the

The starter motor is used to turn the engine flywheel fast enough to get the engine to start running.The starter motor has a solenoid. When the start switch is activated, the solenoid will move the starter pinion to engage it with the ring gear on the flywheel of the engine. The starter pinion will engage with the ring gear before the electric contacts in the solenoid close the circuit between the battery and the starter motor. When the circuit between the battery and the starter motor is complete, the pinion will turn the engine flywheel. A clutch gives protection for the starter motor so that the engine cannot turn the starter motor too fast. When the start switch is released, the starter pinion will move away from the ring gear.

Starter Motor Cross Section

(1) Field. (2) Solenoid. (3) Clutch. (4) Pinion. (5) Commutator. (6) Brush assembly. (7) Armature.Other Components

Circuit Breaker

Circuit Breaker Schematic

(1) Reset button. (2) Disc in open position. (3) Contacts. (4) Disc. (5) Battery circuit terminals.The circuit breaker is a switch that opens the battery circuit if the current in the electrical system goes higher than the rating of the circuit breaker.A heat activated metal disc with a contact point makes complete the electric circuit through the circuit breaker. If the current in the electrical system gets too high, it causes the metal disc to get hot. This heat causes a distortion of the metal disc which opens the contacts and breaks the circuit. A circuit breaker that is open can be reset (an adjustment to make the circuit complete again) after it becomes cool. Push the reset button to close the contacts and reset the circuit breaker.Jake Brake

The JAKE BRAKE permits the operator to control the speed of the vehicle on grades, curves, or anytime when speed reduction is necessary, but long applications of the service brakes are not desired. In downhill operation, or any slow down condition, the engine crankshaft is turned by the rear wheels (through the differential, driveshaft, transmission and clutch). To reduce the speed of the vehicle, an application of a braking force can be made to the pistons of the engine.The JAKE BRAKE, when activated, does this through the conversion of the engine from a source of power to an air compressor that absorbs (takes) power. This conversion is made possible by a master to slave piston arrangement, where movement of the rocker arm for the exhaust valve of one cylinder is transferred hydraulically to open the exhaust valve of another cylinder near the top of its normal compression stroke cycle. The compressed cylinder charge is now released into the exhaust manifold.The release of the compressed air pressure to the atmosphere prevents the return of energy to the engine piston on the expansion (power) stroke. The result is an energy loss, since the work done by the compression of the cylinder charge is not returned by the expansion process. This energy loss is taken from the rear wheels, which provides the