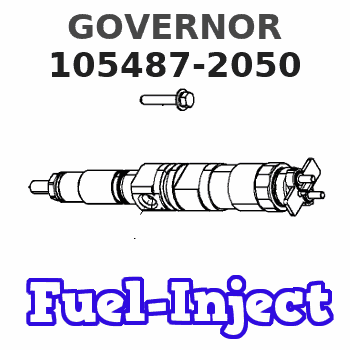

Information governor

BOSCH

F 019 Z2F 003

f019z2f003

ZEXEL

105487-2050

1054872050

Rating:

Scheme ###:

| 1. | [1] | 154004-5200 | GOVERNOR HOUSING |

| 9. | [1] | 154353-5601 | PLATE |

| 10. | [4] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 11. | [4] | 020106-1840 | BLEEDER SCREW M6P1L18 |

| 12. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 13. | [1] | 029240-6010 | UNION NUT M6P1.0H5* |

| 14. | [2] | 154011-0100 | HEXAGON NUT |

| 14. | [2] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154513-8020 | GOVERNOR COVER |

| 35/2. | [1] | 154321-2000 | BUSHING |

| 35/3. | [1] | 029621-0080 | PACKING RING |

| 38. | [1] | 154031-3401 | FLAT-HEAD SCREW |

| 39. | [1] | 029201-0160 | UNION NUT |

| 47. | [2] | 154036-2000 | CAPSULE |

| 47. | [2] | 154036-2000 | CAPSULE |

| 48. | [1] | 154010-5500 | BLEEDER SCREW M10P1.25L42 |

| 49. | [1] | 154011-2100 | UNION NUT |

| 50. | [1] | 155615-2300 | FLAT-HEAD SCREW |

| 51. | [5] | 020106-4540 | BLEEDER SCREW M6P1.0L45 |

| 52. | [2] | 029010-6850 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 54. | [2] | 014110-6440 | LOCKING WASHER |

| 65. | [1] | 153021-5000 | CAP |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154063-2500 | COVER |

| 82. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 83. | [1] | 029020-6210 | BLEEDER SCREW |

| 84. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 86. | [1] | 029020-6210 | BLEEDER SCREW |

| 100. | [1] | 154100-9220 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 139212-0000 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-9600 | GOVERNOR SPRING |

| 132. | [1] | 154154-0701 | COILED SPRING |

| 140. | [1] | 154183-2320 | HEADLESS SCREW |

| 141. | [1] | 139218-0100 | UNION NUT |

| 150. | [1] | 154200-5801 | SWIVELLING LEVER |

| 151. | [1] | 154200-5501 | BUSHING |

| 152. | [2] | 139700-0000 | O-RING |

| 152. | [2] | 139700-0000 | O-RING |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 154. | [1] | 139610-0101 | PACKING RING |

| 155. | [1] | 139411-0100 | SHIM D22.0&12.0T0.40 |

| 156. | [0] | 139411-0200 | SHIM D18.0&12.0T0.10 |

| 156B. | [0] | 139411-0300 | SHIM D18.0&12.0T0.20 |

| 156C. | [0] | 139411-0400 | SHIM D18.0&12.0T0.30 |

| 157. | [1] | 154204-3500 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2300 | BUSHING |

| 161. | [0] | 154206-2400 | PLAIN WASHER D20.5&12.2T1 |

| 170. | [1] | 154216-7120 | FORK LEVER |

| 173. | [1] | 016010-0540 | LOCKING WASHER |

| 174. | [1] | 154234-3220 | STRAP |

| 179. | [1] | 154238-0201 | BEARING PIN |

| 180. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-5200 | TENSIONING LEVER |

| 182. | [1] | 154237-1200 | BEARING PIN |

| 183. | [2] | 154237-1300 | BUSHING |

| 183. | [2] | 154237-1300 | BUSHING |

| 190. | [1] | 154360-2700 | CONTROL LEVER |

| 191. | [1] | 154340-1920 | CONTROL LEVER |

| 192. | [1] | 020006-1670 | BLEEDER SCREW M6P1L16 7T |

| 203/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 203/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 203/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 203/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 203/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 203/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 203/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 203/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 203/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 203/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 203/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 205. | [1] | 154324-3400 | LEVER SHAFT |

| 207. | [1] | 154326-0300 | CONTROL LEVER |

| 211. | [1] | 016010-0840 | LOCKING WASHER |

| 220. | [1] | 154050-6820 | HEADLESS SCREW |

| 221. | [1] | 029201-2140 | UNION NUT |

| 222. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 223. | [1] | 154159-1200 | CAP NUT |

| 235. | [1] | 155412-5300 | IMPELLER WHEEL |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0200 | GASKET |

| 238. | [1] | 139700-0100 | O-RING |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Include in #1:

106692-4212

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

1. Remove the pickup from the injection line. Check to be sure the pickup and injection line are clean and dry. The inner bore of the pickup that contacts the injection line must be clean and dry. If necessary, clean the inner bore with a soft dry cloth. If the pickup is damp, dry it in an oven at approximately 50°C (122°F) before reinstalling on the fuel injection line.2. Check the fuel injection line on which the pickup was installed. Make sure all paint has been removed from around the line and that clean bare metal is exposed. Use fine emery paper to clean the line if necessary.3. Reinstall the pickup on the fuel injection line. Make sure the thumbscrew is tight and the pickup is not touching anything except the line. Observe the NO INPUT SIGNAL light and the digital readout on the multitach. If the light stays on bright all the time and the digital display reads 0 when the engine is running, the pickup is not operating. Remove the pickup and amplifier, and test the pickup and amplifier as shown on pages 6 and 7, or use a different pickup and amplifier.4. If the pickup is operating but the NO INPUT SIGNAL light and digital readout are erratic, the pickup output signal is either too low or it is noisy. Run the engine at low and high speeds. If the output signal is too low, the pickup will operate better at high engine speeds. If the signal is noisy, the pickup will usually perform better at low engine speeds. To correct either of these problems, loosen the thumbscrew and rotate the pickup to a new position on the line. Tighten the thumbscrew. Check to see if this solves the problem. To correct noisy operation, it may also be necessary to remove the pickup and reverse it 180° so the signal line points in the opposite direction.5. If pickup operation is still erratic after performing the previous steps, move the pickup to a new location on the same line or to a different line. Make sure each new location is properly prepared before installing pickup. To correct noisy operation (erratic signal and high speed readings), try a pickup location as close as possible to a point where the injection line is fastened to the engine.(D) Use Of The Pickup During Wet Conditions

If the pickup becomes wet, it may operate intermittently or not at all. Although the pickup is water resistant, it is not waterproof. Water spray from rain or other sources may cause the pickup to stop producing an output signal. If this happens, the pickup should be removed from the engine and allowed to dry out thoroughly. If necessary, the pickup can be dried in an oven at approximately 50°C (122°F). After drying, the pickup should operate correctly. If it is not possible to keep the pickup dry, use the following procedure. If the pickup must be used during wet conditions, it may be possible

If the pickup becomes wet, it may operate intermittently or not at all. Although the pickup is water resistant, it is not waterproof. Water spray from rain or other sources may cause the pickup to stop producing an output signal. If this happens, the pickup should be removed from the engine and allowed to dry out thoroughly. If necessary, the pickup can be dried in an oven at approximately 50°C (122°F). After drying, the pickup should operate correctly. If it is not possible to keep the pickup dry, use the following procedure. If the pickup must be used during wet conditions, it may be possible