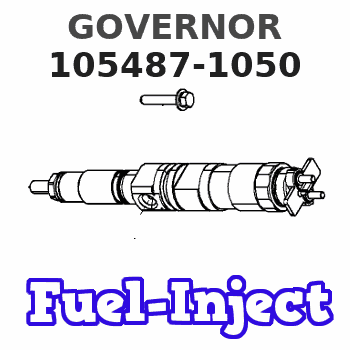

Information governor

ZEXEL

105487-1050

1054871050

MITSUBISHI

ME056303

me056303

Rating:

Scheme ###:

| 1. | [1] | 154004-1720 | GOVERNOR HOUSING |

| 9. | [1] | 154350-6000 | PLATE |

| 10. | [8] | 020106-2040 | BLEEDER SCREW |

| 10. | [8] | 020106-2040 | BLEEDER SCREW |

| 12. | [1] | 154010-7300 | BLEEDER SCREW |

| 13. | [1] | 013020-6040 | UNION NUT |

| 14. | [1] | 013020-8040 | UNION NUT |

| 14. | [1] | 013020-8040 | UNION NUT |

| 14B. | [1] | 154011-2300 | UNION NUT |

| 15. | [2] | 029620-8050 | PACKING RING |

| 15. | [2] | 029620-8050 | PACKING RING |

| 16. | [1] | 155004-3300 | LEVER SHAFT |

| 17. | [1] | 154408-1520 | CONTROL LEVER |

| 18. | [1] | 155003-1920 | CONTROL LEVER |

| 19. | [1] | 155006-0100 | BLEEDER SCREW |

| 20. | [1] | 029300-8010 | PLAIN WASHER |

| 20B. | [1] | 029300-8030 | PLAIN WASHER |

| 21. | [1] | 016010-0740 | LOCKING WASHER |

| 22. | [1] | 029310-8040 | SHIM |

| 22. | [1] | 029310-8040 | SHIM |

| 22B. | [1] | 029310-8050 | SHIM |

| 23. | [1] | 025520-1210 | SPLIT PIN |

| 24. | [1] | 154206-2000 | BUSHING |

| 25. | [1] | 154327-5200 | COILED SPRING |

| 26. | [1] | 154364-6200 | CONTROL LEVER |

| 27. | [1] | 014110-8440 | LOCKING WASHER |

| 28. | [1] | 013020-8040 | UNION NUT |

| 35. | [1] | 154513-2020 | GOVERNOR COVER |

| 35/2. | [1] | 154321-1800 | BUSHING |

| 35/3. | [1] | 029621-0080 | PACKING RING |

| 38. | [1] | 154031-3500 | FLAT-HEAD SCREW |

| 39. | [1] | 154011-1600 | UNION NUT |

| 47. | [1] | 154036-0300 | CAPSULE |

| 47. | [1] | 154036-0300 | CAPSULE |

| 48. | [1] | 154010-7700 | BLEEDER SCREW |

| 49. | [1] | 154011-2200 | UNION NUT |

| 50. | [1] | 155615-1900 | BLEEDER SCREW |

| 51. | [4] | 020106-3840 | BLEEDER SCREW |

| 51. | [4] | 020106-3840 | BLEEDER SCREW |

| 52. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-7300 | BLEEDER SCREW |

| 65. | [1] | 155404-1700 | CAP |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154060-4900 | COVER |

| 82. | [1] | 029020-6210 | BLEEDER SCREW |

| 83. | [1] | 020006-1640 | BLEEDER SCREW |

| 84. | [1] | 029020-6210 | BLEEDER SCREW |

| 86. | [1] | 020006-1640 | BLEEDER SCREW |

| 100. | [1] | 154100-9620 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118. | [1] | 029998-1000 | SHIM |

| 118/1. | [1] | 029311-0010 | SHIM |

| 118/1. | [1] | 029311-0180 | SHIM |

| 118/1. | [1] | 029311-0190 | SHIM |

| 118/1. | [1] | 029311-0210 | SHIM |

| 118/1. | [1] | 139410-0000 | SHIM |

| 118/1. | [1] | 139410-0100 | SHIM |

| 130. | [1] | 154150-6200 | GOVERNOR SPRING |

| 132. | [1] | 154154-1200 | COILED SPRING |

| 140. | [1] | 154178-2120 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-3800 | SWIVELLING LEVER |

| 151. | [2] | 154204-2000 | BUSHING |

| 151. | [2] | 154204-2000 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [1] | 029998-1130 | SHIM |

| 156/1. | [1] | 029311-1110 | SHIM |

| 156/1. | [1] | 029311-1120 | SHIM |

| 156/1. | [1] | 029311-1130 | SHIM |

| 157. | [1] | 029141-7010 | CAPSULE |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-0900 | BUSHING |

| 161. | [1] | 154206-0200 | PLAIN WASHER |

| 170. | [1] | 154216-2520 | GUIDE LEVER |

| 170/5. | [1] | 026110-0510 | LOCKING WASHER |

| 170/7. | [1] | 154225-4820 | FULCRUM LEVER |

| 170/8. | [1] | 154325-0600 | SLOTTED WASHER |

| 170/10. | [1] | 016110-1010 | LOCKING WASHER |

| 170/11. | [1] | 154325-0700 | SLOTTED WASHER |

| 170/12. | [1] | 016010-0710 | LOCKING WASHER |

| 173. | [1] | 016010-0540 | LOCKING WASHER |

| 174. | [1] | 154230-8020 | STRAP |

| 175. | [1] | 154222-4900 | BEARING PIN |

| 176. | [1] | 155402-3800 | SAFETY PIN |

| 177. | [1] | 029310-5170 | SHIM |

| 179. | [1] | 154238-0301 | BEARING PIN |

| 180. | [1] | 016010-0540 | LOCKING WASHER |

| 180. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-5300 | TENSIONING LEVER |

| 182. | [1] | 154237-1400 | BEARING PIN |

| 183. | [2] | 154237-0600 | BUSHING |

| 190. | [1] | 154360-2800 | CONTROL LEVER |

| 191. | [1] | 154340-0120 | CONTROL LEVER |

| 192. | [1] | 020006-1670 | BLEEDER SCREW |

| 193. | [1] | 154362-1020 | CONTROL LEVER |

| 194. | [2] | 020006-1240 | BLEEDER SCREW |

| 203. | [1] | 029998-1050 | SHIM |

| 203/1. | [1] | 029311-0640 | SHIM |

| 203/1. | [1] | 029311-0650 | SHIM |

| 203/1. | [1] | 029311-0660 | SHIM |

| 203/1. | [1] | 029311-0670 | SHIM |

| 203/1. | [1] | 029311-0680 | SHIM |

| 203/1. | [1] | 029311-0690 | SHIM |

| 203/1. | [1] | 029311-0700 | SHIM |

| 203/1. | [1] | 139410-1400 | SHIM |

| 203/1. | [1] | 139410-1500 | SHIM |

| 203/1. | [1] | 139410-1600 | SHIM |

| 205. | [1] | 154324-3000 | LEVER SHAFT |

| 207. | [1] | 154326-0300 | CONTROL LEVER |

| 211. | [1] | 016010-0840 | LOCKING WASHER |

| 220. | [1] | 154050-6220 | HEADLESS SCREW |

| 221. | [1] | 029201-2140 | UNION NUT |

| 222. | [2] | 026512-1540 | GASKET |

| 223. | [1] | 154159-1200 | CAP NUT |

| 235. | [1] | 155412-5200 | IMPELLER WHEEL |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 250. | [1] | 154407-5920 | MANIFOLD-PRESSURE COMP. |

| 250/1. | [1] | 154408-6220 | DIAPHRAGM HOUSING |

| 250/2. | [3] | 020106-1640 | BLEEDER SCREW |

| 250/3. | [1] | 029010-6380 | BLEEDER SCREW |

| 250/4. | [1] | 154400-5101 | STOP PIN |

| 250/5. | [1] | 153400-0700 | SLOTTED WASHER |

| 250/6. | [1] | 016010-0740 | LOCKING WASHER |

| 250/7. | [1] | 029312-0180 | SHIM |

| 250/7B. | [1] | 029312-0210 | SHIM |

| 250/8. | [1] | 154403-9500 | COILED SPRING |

| 250/9. | [1] | 029310-8010 | PLAIN WASHER |

| 250/9B. | [1] | 029310-8020 | PLAIN WASHER |

| 250/10. | [1] | 154411-0200 | COILED SPRING |

| 250/11. | [1] | 153400-0800 | SPRING SEAT |

| 250/12. | [1] | 014110-5440 | LOCKING WASHER |

| 250/13. | [1] | 013030-5240 | UNION NUT |

| 250/14. | [1] | 154400-5200 | BLEEDER SCREW |

| 250/15. | [1] | 154400-0720 | DIAPHRAGM |

| 250/16. | [1] | 029330-8050 | GASKET |

| 250/17. | [1] | 026506-1040 | GASKET |

| 250/18. | [1] | 023040-6040 | UNION NUT |

| 250/20. | [1] | 154404-3600 | COVER |

| 250/21. | [3] | 029010-6310 | BLEEDER SCREW |

| 250/22. | [3] | 014110-6440 | LOCKING WASHER |

| 250/23. | [1] | 154404-1100 | FLAT-HEAD SCREW |

| 250/24. | [1] | 023040-6040 | UNION NUT |

| 250/25. | [1] | 154406-7800 | CAP NUT |

| 250/26. | [1] | 026506-1040 | GASKET |

| 250/27. | [1] | 029010-6010 | CAPSULE |

| 250/28. | [2] | 026510-1340 | GASKET |

| 250/30. | [1] | 029731-0120 | EYE BOLT |

| 250/33. | [2] | 154413-2600 | GASKET |

| 251. | [1] | 154390-2000 | GASKET |

| 252. | [1] | 154232-1220 | PLATE |

| 253. | [1] | 029320-5020 | LOCKING WASHER |

| 254. | [1] | 010535-1040 | FLAT-HEAD SCREW |

| 500. | [1] | 154601-0220 | LOAD SENSOR |

| 500/2. | [1] | 154603-0820 | BRACKET |

| 500/3. | [1] | 154604-2201 | JOINT CONNECTION |

| 500/5. | [1] | 154603-1000 | CONTROL LEVER |

| 500/6. | [1] | 029310-8540 | SHIM |

| 500/7. | [1] | 014110-6440 | LOCKING WASHER |

| 500/8. | [1] | 013020-6040 | UNION NUT |

| 500/9. | [2] | 020144-1240 | BLEEDER SCREW |

| 500/10. | [1] | 154604-0200 | CLAMPING BAND |

| 500/11. | [1] | 014010-4140 | PLAIN WASHER |

| 500/12. | [1] | 012154-0840 | FLAT-HEAD SCREW |

| 500/13. | [1] | 029310-8520 | SHIM |

| 501. | [1] | 154354-3800 | UNION NUT |

| 502. | [1] | 154604-1200 | CLEVIS |

| 503. | [1] | 013020-6040 | UNION NUT |

| 504. | [1] | 154351-9400 | CLEVIS |

| 505. | [1] | 029200-6210 | UNION NUT |

| 506. | [2] | 154604-2400 | BEARING PIN |

| 507. | [2] | 016010-0640 | LOCKING WASHER |

| 511. | [1] | 020118-1440 | BLEEDER SCREW |

| 512. | [1] | 154604-0200 | CLAMPING BAND |

| 513. | [1] | 014010-4140 | PLAIN WASHER |

| 514. | [1] | 012154-0640 | FLAT-HEAD SCREW |

Include in #1:

106651-2100

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

When the preset temperature, pressure or fluid level occurs, either a light or an audible alarm will be energized. The light or alarm will continue to operate until the condition is corrected. When the condition is corrected the alarm will automatically reset and the light will turn off.

The cause of the shutdown must be investigated and corrected before starting and operating the engine.

Testing Indicator Lights

Most control panels are equipped with a test switch. By turning the switch ON, all of the indicator lights can be checked for proper operation. Test the indicator lights periodically, replace burned out light bulbs immediately.Alarm Shutoff Switch

A switch may be installed in the alarm circuit for silencing the alarm while the engine is stopped for repairs. Be sure the switch is moved to the closed (ON) position and the warning lights are lit before starting.

Place switch in the closed (ON) position when the engine is started, so the engine will be protected.

Output Shaft Governor Operation

When the load can overspeed the torque converter output shaft, an output shaft governor should be installed. The output shaft governor is a speed limiting device which automatically adjusts engine governor setting according to load requirement.Determining Cause Of Shutdown

If the engine has been shutdown by a safety device, do not start the engine and place it into service without having the cause of the shutdown investigated and corrected.

Low Oil Pressure Checks

If the low oil pressure shutoff control has stopped the engine, make the following checks: 1. Check the water temperature gauge. Determine if the engine was overheated. Check for external water leaks.

Beware of steam or scalding water. Do not attempt to loosen the radiator cap until the temperature gauge indicates the coolant has sufficiently cooled. Then, loosen the cap slowly.

2. Check the oil level. Oil level must be between the ADD and FULL marks on the side of the dipstick stamped CHECK WITH ENGINE STOPPED.3. If the oil level is below the ADD mark, check for oil spray and/or oil accumulations. If any are found, have the necessary repairs made. Before starting, add oil to the FULL mark.4. Reset the shutoff control.5. Remove the load and start the engine at its slowest speed. Be prepared to shut the engine down manually.6. Be alert for unusual sounds or noises. If the engine knocks, stop the engine immediately and call your Caterpillar dealer.7. If the engine blows excessive black exhaust or has excessive crankcase blow-by, the engine may need reconditioning. Stop the engine and call your Caterpillar dealer.8. If the engine runs satisfactorily, observe the oil pressure gauge. If satisfactory pressure is not indicated, shut the engine down; call your Caterpillar dealer.9. If proper oil pressure is registered, check to see if the reset knob has moved to the run position. If the knob does not move, stop the engine. Check the shutoff control, the oil line, and the oil pressure gauge. Have necessary repairs made.10. If the oil pressure gauge registers normal oil pressure, if the knob on the shutoff

The cause of the shutdown must be investigated and corrected before starting and operating the engine.

Testing Indicator Lights

Most control panels are equipped with a test switch. By turning the switch ON, all of the indicator lights can be checked for proper operation. Test the indicator lights periodically, replace burned out light bulbs immediately.Alarm Shutoff Switch

A switch may be installed in the alarm circuit for silencing the alarm while the engine is stopped for repairs. Be sure the switch is moved to the closed (ON) position and the warning lights are lit before starting.

Place switch in the closed (ON) position when the engine is started, so the engine will be protected.

Output Shaft Governor Operation

When the load can overspeed the torque converter output shaft, an output shaft governor should be installed. The output shaft governor is a speed limiting device which automatically adjusts engine governor setting according to load requirement.Determining Cause Of Shutdown

If the engine has been shutdown by a safety device, do not start the engine and place it into service without having the cause of the shutdown investigated and corrected.

Low Oil Pressure Checks

If the low oil pressure shutoff control has stopped the engine, make the following checks: 1. Check the water temperature gauge. Determine if the engine was overheated. Check for external water leaks.

Beware of steam or scalding water. Do not attempt to loosen the radiator cap until the temperature gauge indicates the coolant has sufficiently cooled. Then, loosen the cap slowly.

2. Check the oil level. Oil level must be between the ADD and FULL marks on the side of the dipstick stamped CHECK WITH ENGINE STOPPED.3. If the oil level is below the ADD mark, check for oil spray and/or oil accumulations. If any are found, have the necessary repairs made. Before starting, add oil to the FULL mark.4. Reset the shutoff control.5. Remove the load and start the engine at its slowest speed. Be prepared to shut the engine down manually.6. Be alert for unusual sounds or noises. If the engine knocks, stop the engine immediately and call your Caterpillar dealer.7. If the engine blows excessive black exhaust or has excessive crankcase blow-by, the engine may need reconditioning. Stop the engine and call your Caterpillar dealer.8. If the engine runs satisfactorily, observe the oil pressure gauge. If satisfactory pressure is not indicated, shut the engine down; call your Caterpillar dealer.9. If proper oil pressure is registered, check to see if the reset knob has moved to the run position. If the knob does not move, stop the engine. Check the shutoff control, the oil line, and the oil pressure gauge. Have necessary repairs made.10. If the oil pressure gauge registers normal oil pressure, if the knob on the shutoff