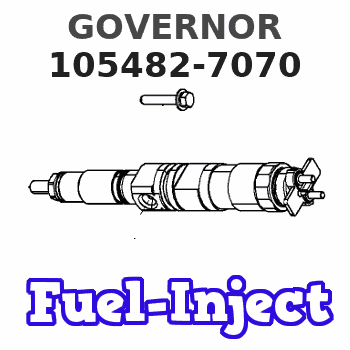

Information governor

BOSCH

F 019 Z3E 940

f019z3e940

ZEXEL

105482-7070

1054827070

HINO

223001600A

223001600a

Rating:

Scheme ###:

| 1. | [1] | 154000-7500 | GOVERNOR HOUSING |

| 6. | [1] | 154007-0200 | ADAPTOR |

| 7. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 9. | [1] | 154350-1800 | PLATE |

| 10. | [5] | 029010-6810 | BLEEDER SCREW |

| 11. | [1] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 12. | [1] | 154010-0200 | FLAT-HEAD SCREW |

| 13. | [1] | 029240-6010 | UNION NUT M6P1.0H5* |

| 14. | [2] | 154011-0100 | HEXAGON NUT |

| 14. | [2] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154512-6220 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0400 | BUSHING |

| 38. | [1] | 154031-3200 | FLAT-HEAD SCREW |

| 39. | [1] | 154011-1600 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 48. | [1] | 154010-3400 | FLAT-HEAD SCREW |

| 49. | [1] | 029240-8000 | UNION NUT |

| 50. | [1] | 155615-0300 | FLAT-HEAD SCREW |

| 51. | [4] | 020106-3840 | BLEEDER SCREW |

| 52. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 65. | [1] | 153043-1620 | STOPPING DEVICE |

| 80. | [1] | 154060-7300 | COVER |

| 82. | [1] | 020006-2040 | BLEEDER SCREW M6P1L20 4T |

| 83. | [1] | 029020-6210 | BLEEDER SCREW |

| 84. | [1] | 029010-6750 | BLEEDER SCREW |

| 86. | [1] | 029020-6260 | BLEEDER SCREW |

| 100. | [1] | 154100-5020 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-0420 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-6000 | GOVERNOR SPRING |

| 132. | [1] | 154154-1300 | COILED SPRING |

| 140. | [1] | 154176-1520 | HEADLESS SCREW |

| 141. | [1] | 029201-6220 | UNION NUT |

| 150. | [1] | 154200-3701 | SWIVELLING LEVER |

| 151. | [1] | 154204-2001 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 153. | [2] | 154354-3900 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156/1. | [0] | 029311-1110 | SHIM D17&11T0.1 |

| 156/1. | [0] | 029311-1120 | SHIM D17&11T0.2 |

| 156/1. | [0] | 029311-1130 | SHIM D17&11T0.3 |

| 157. | [1] | 154204-3400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-0900 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154211-2920 | FORK LEVER |

| 173. | [1] | 016010-0540 | LOCKING WASHER |

| 174. | [1] | 154230-3920 | STRAP |

| 181. | [1] | 154236-3620 | TENSIONING LEVER |

| 182. | [1] | 154237-0400 | BEARING PIN |

| 183. | [2] | 154237-0600 | BUSHING |

| 183. | [2] | 154237-0600 | BUSHING |

| 190. | [1] | 154302-8420 | CONTROL LEVER |

| 191. | [1] | 154342-0820 | CONTROL LEVER |

| 192. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 198. | [1] | 014110-8440 | LOCKING WASHER |

| 201. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 203/1. | [0] | 029311-0640 | SHIM D26.0&10.2T0.95 |

| 203/1. | [0] | 029311-0650 | SHIM D26.0&10.2T0.20 |

| 203/1. | [0] | 029311-0660 | SHIM D26.0&10.2T0.25 |

| 203/1. | [0] | 029311-0670 | SHIM D26.0&10.2T0.30 |

| 203/1. | [0] | 029311-0680 | SHIM D26.0&10.2T0.35 |

| 203/1. | [0] | 029311-0690 | SHIM D26.0&10.2T0.40 |

| 203/1. | [0] | 029311-0700 | SHIM D26.0&10.2T0.50 |

| 203/1. | [0] | 139410-1400 | SHIM D26&10.2T0.7 |

| 203/1. | [0] | 139410-1500 | SHIM D26&10.2T0.9 |

| 203/1. | [0] | 139410-1600 | SHIM D26&10.2T0.8 |

| 203/1. | [0] | 139410-2700 | SHIM D26&10.2T0.6 |

| 205. | [1] | 154324-1200 | LEVER SHAFT |

| 207. | [1] | 154326-0300 | CONTROL LEVER |

| 208. | [1] | 154327-2100 | COILED SPRING |

| 211. | [1] | 016010-0840 | LOCKING WASHER |

| 220. | [1] | 154050-3520 | HEADLESS SCREW |

| 221. | [1] | 029201-2140 | UNION NUT |

| 222. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 223. | [1] | 154159-1200 | CAP NUT |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 255. | [1] | 154213-2220 | BRACKET |

| 256. | [1] | 154316-7520 | BRACKET |

| 257. | [3] | 010065-1140 | BLEEDER SCREW M5P0.8L11 |

| 258. | [3] | 014110-5440 | LOCKING WASHER |

| 306. | [1] | 155402-6320 | PLATE |

| 331. | [1] | 154176-0520 | HEADLESS SCREW |

| 332. | [1] | 029201-6250 | UNION NUT |

| 335. | [1] | 154352-2600 | CAPSULE |

| 336. | [1] | 029331-6030 | GASKET |

| 340. | [1] | 154176-0620 | HEADLESS SCREW |

| 341. | [1] | 029201-6080 | UNION NUT |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105482-7070

223001600A HINO

GOVERNOR

K 14JN MECHANICAL GOVERNOR GOV RFD GOV

K 14JN MECHANICAL GOVERNOR GOV RFD GOV

Information:

Above 16°C (60°F)

Consult the "Operation" (Operator's) Guide for before starting checks. 1. Turn on the scraper disconnect switch. 2. Move the scraper governor to just past ENGINE STOPPED detent. 3. Push in and turn the start switch to START. Release the switch when the engine starts.

After every 30 seconds of cranking, allow 2 minutes for the starting motor to cool.

4. If the engine oil pressure gauge doesn't register within 10 seconds, push the governor control to the ENGINE STOPPED position to stop the engine. Have corrections made.5. Keep the engine at low idle until the systems are warm.6. Watch all gauges and indicators for correct readings before moving the machine.16°C (60°F) to -12°C (10°F)

1. Follow the steps under "Above 16°C (60°F)."

If the engine does not start after two attempts, use starting fluid. This will prevent excessive battery drain and starting motor overheating.

2. Use starting fluid by pushing the button under the start switch, at 2 second intervals, while cranking the engine. See "Ether Aids" under "Cold Weather Starting Aids."-12°C (10°F) to -26°C (-15°F)

1. Follow the steps under "Above 16°C (60°F)."2. Coolant heaters are required.3. An external battery source may be required if the battery charge is not maintained. See "Boost Starting" under "Cold Weather Starting Aids."4. Starting fluid is required. See "Ether Aids" under "Cold Weather Starting Aids."Below -26°C (-15°F)

1. Follow the steps under "Above 16°C (60°F)."2. Coolant heaters are required.3. An external battery source may be required. See "Boost Starting" under "Cold Weather Starting Aids."4. Starting fluid is required. See "Ether Aids" under "Cold Weather Starting Aids."5. Special lubricants are required. Consult your Caterpillar dealer or refer to Caterpillar Form Number SEBU5338, "Operation, Lubrication and Maintenance Guide for Cold Weather Operation."Starting Aids

Winter Oils

The use of SAE10W viscosity oil in the compartments listed on the chart below will aid in cold weather starting.

Use SAE10W oil only in the temperature ranges indicated.

At lower than above temperatures consult your Caterpillar dealer or refer to the "Operation, Lubrication and Maintenance Guide for Cold Weather Operation," Caterpillar Form Number SEBU5338, for the correct lubricants to use.Ether Aids

Ether is a poison and is flammable.Use it only in well ventilated areas.Use it with care to avoid fires.Avoid breathing the ether vapors, or repeated contact of ether with skin.Do not use ether in environments above 90°C (200°F).

Ether is to be used for cold starting purposes only. Use ether only while cranking the engine. Use it sparingly. Excessive ether can cause piston and ring damage.

Push the button only while cranking the engine.A metered amount of starting fluid (ether) is released each time the button is pushed.After pushing the button, allow 2 seconds before pushing it again.Continue the use of starting fluid every 2 seconds after the engine starts, until it is running smoothly.Batteries

Keep batteries charged to a corrected specific gravity of 1.250 or above. Otherwise, an external electrical source may be required.Boost Starting

Do not allow cable ends to contact each other or the machine.Prevent sparks near the batteries. They could cause battery vapors (hydrogen) to explode.

When

Consult the "Operation" (Operator's) Guide for before starting checks. 1. Turn on the scraper disconnect switch. 2. Move the scraper governor to just past ENGINE STOPPED detent. 3. Push in and turn the start switch to START. Release the switch when the engine starts.

After every 30 seconds of cranking, allow 2 minutes for the starting motor to cool.

4. If the engine oil pressure gauge doesn't register within 10 seconds, push the governor control to the ENGINE STOPPED position to stop the engine. Have corrections made.5. Keep the engine at low idle until the systems are warm.6. Watch all gauges and indicators for correct readings before moving the machine.16°C (60°F) to -12°C (10°F)

1. Follow the steps under "Above 16°C (60°F)."

If the engine does not start after two attempts, use starting fluid. This will prevent excessive battery drain and starting motor overheating.

2. Use starting fluid by pushing the button under the start switch, at 2 second intervals, while cranking the engine. See "Ether Aids" under "Cold Weather Starting Aids."-12°C (10°F) to -26°C (-15°F)

1. Follow the steps under "Above 16°C (60°F)."2. Coolant heaters are required.3. An external battery source may be required if the battery charge is not maintained. See "Boost Starting" under "Cold Weather Starting Aids."4. Starting fluid is required. See "Ether Aids" under "Cold Weather Starting Aids."Below -26°C (-15°F)

1. Follow the steps under "Above 16°C (60°F)."2. Coolant heaters are required.3. An external battery source may be required. See "Boost Starting" under "Cold Weather Starting Aids."4. Starting fluid is required. See "Ether Aids" under "Cold Weather Starting Aids."5. Special lubricants are required. Consult your Caterpillar dealer or refer to Caterpillar Form Number SEBU5338, "Operation, Lubrication and Maintenance Guide for Cold Weather Operation."Starting Aids

Winter Oils

The use of SAE10W viscosity oil in the compartments listed on the chart below will aid in cold weather starting.

Use SAE10W oil only in the temperature ranges indicated.

At lower than above temperatures consult your Caterpillar dealer or refer to the "Operation, Lubrication and Maintenance Guide for Cold Weather Operation," Caterpillar Form Number SEBU5338, for the correct lubricants to use.Ether Aids

Ether is a poison and is flammable.Use it only in well ventilated areas.Use it with care to avoid fires.Avoid breathing the ether vapors, or repeated contact of ether with skin.Do not use ether in environments above 90°C (200°F).

Ether is to be used for cold starting purposes only. Use ether only while cranking the engine. Use it sparingly. Excessive ether can cause piston and ring damage.

Push the button only while cranking the engine.A metered amount of starting fluid (ether) is released each time the button is pushed.After pushing the button, allow 2 seconds before pushing it again.Continue the use of starting fluid every 2 seconds after the engine starts, until it is running smoothly.Batteries

Keep batteries charged to a corrected specific gravity of 1.250 or above. Otherwise, an external electrical source may be required.Boost Starting

Do not allow cable ends to contact each other or the machine.Prevent sparks near the batteries. They could cause battery vapors (hydrogen) to explode.

When