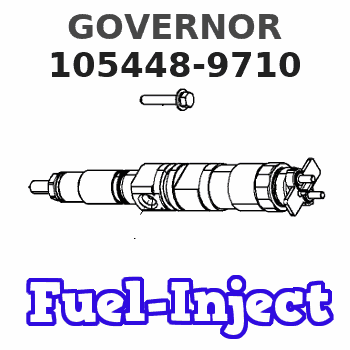

Information governor

BOSCH

F 019 Z1F 226

f019z1f226

ZEXEL

105448-9710

1054489710

Rating:

Scheme ###:

| 1. | [1] | 154002-2920 | GOVERNOR HOUSING |

| 5. | [1] | 154007-1600 | CAPSULE |

| 8. | [9] | 029300-6040 | PLAIN WASHER D11&6.4T1 |

| 9. | [9] | 029320-6010 | LOCKING WASHER |

| 10. | [9] | 029000-6490 | BLEEDER SCREW M6P1.0L23 |

| 12. | [1] | 154010-3900 | BLEEDER SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154520-2420 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0200 | BUSHING |

| 38. | [1] | 154031-3800 | FLAT-HEAD SCREW |

| 39. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [4] | 029000-6470 | BLEEDER SCREW |

| 52. | [5] | 029000-6480 | BLEEDER SCREW M6P1.0L35 |

| 53. | [1] | 154010-0200 | FLAT-HEAD SCREW |

| 55. | [9] | 029320-6010 | LOCKING WASHER |

| 55. | [9] | 029320-6010 | LOCKING WASHER |

| 56. | [9] | 029300-6040 | PLAIN WASHER D11&6.4T1 |

| 56. | [9] | 029300-6040 | PLAIN WASHER D11&6.4T1 |

| 65. | [1] | 153020-3920 | STOPPING DEVICE |

| 66. | [1] | 029332-0050 | GASKET |

| 80. | [1] | 154063-7700 | COVER |

| 82. | [1] | 029020-6240 | BLEEDER SCREW |

| 83. | [1] | 139006-2500 | BLEEDER SCREW M6P1.0L23 |

| 84. | [1] | 029020-6290 | BLEEDER SCREW |

| 86. | [1] | 029020-6290 | BLEEDER SCREW |

| 100. | [1] | 154100-9920 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 104. | [1] | 154120-0100 | PLAIN WASHER |

| 106. | [1] | 029602-0020 | LOCKING WASHER |

| 107. | [1] | 154121-0500 | TOOTHED GEAR |

| 108. | [1] | 016610-2640 | BEARING PLATE |

| 109. | [1] | 028102-0010 | BEARING PLATE |

| 111. | [1] | 154134-0000 | SPACER BUSHING |

| 112. | [1] | 154122-0300 | COVER |

| 113. | [1] | 029614-7020 | LOCKING WASHER |

| 114. | [1] | 025803-1610 | WOODRUFF KEY |

| 115. | [1] | 029321-2020 | LOCKING WASHER |

| 116. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-1020 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 119. | [1] | 154130-1920 | TOOTHED GEAR |

| 119/1. | [1] | 154130-0510 | TOOTHED GEAR |

| 119/2. | [1] | 154132-0320 | HOLDER |

| 119/3. | [4] | 153251-0600 | DAMPER |

| 119/4. | [1] | 139329-0000 | PLAIN WASHER |

| 119/5. | [1] | 016020-2810 | LOCKING WASHER |

| 122. | [3] | 020106-2840 | BLEEDER SCREW |

| 132. | [1] | 154154-2900 | COILED SPRING |

| 133. | [2] | 154156-0100 | TUBE |

| 134. | [1] | 154158-3320 | HEADLESS SCREW |

| 136. | [1] | 029201-2290 | UNION NUT |

| 137. | [2] | 026512-1640 | GASKET D15.9&12.2T1 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154185-4920 | HEADLESS SCREW |

| 141. | [1] | 029201-6080 | UNION NUT |

| 150. | [1] | 154200-4520 | SWIVELLING LEVER |

| 151. | [1] | 154204-2100 | BUSHING |

| 152. | [2] | 029631-6110 | O-RING |

| 152. | [2] | 029631-6110 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 029621-1070 | PACKING RING |

| 155. | [1] | 029311-1010 | SHIM |

| 158. | [1] | 154204-2200 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 170. | [1] | 154211-5220 | FORK LEVER |

| 174. | [1] | 154230-1820 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 176. | [1] | 154232-0500 | CONNECTOR |

| 177. | [1] | 154316-2300 | BLEEDER SCREW |

| 178. | [1] | 029320-6010 | LOCKING WASHER |

| 181. | [1] | 154236-5721 | TENSIONING LEVER |

| 182. | [1] | 154237-0200 | BEARING PIN |

| 190. | [1] | 154347-9520 | CONTROL LEVER |

| 191. | [1] | 154367-1320 | CONTROL LEVER |

| 192. | [1] | 020006-2070 | BLEEDER SCREW M6P1L20 7T |

| 195. | [1] | 154317-2600 | COILED SPRING |

| 201. | [1] | 029630-9160 | O-RING |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5020 | CONTROL LEVER |

| 208. | [1] | 154327-7600 | COILED SPRING |

| 211/1. | [0] | 029311-0520 | SHIM D20.8&10.3T0.2 |

| 211/1. | [0] | 029311-0530 | SHIM D20.8&10.3T0.25 |

| 211/1. | [0] | 029311-0540 | SHIM D20.8&10.3T0.3 |

| 211/1. | [0] | 029311-0550 | SHIM D20.8&10.3T0.35 |

| 211/1. | [0] | 029311-0560 | SHIM D20.8&10.3T0.4 |

| 211/1. | [0] | 029311-0570 | SHIM D20.8&10.3T0.5 |

| 236. | [1] | 154390-2900 | GASKET |

| 237. | [1] | 154390-3100 | GASKET |

| 238. | [1] | 154390-3500 | GASKET |

| 331. | [1] | 154179-0720 | HEADLESS SCREW |

| 332. | [1] | 029201-6010 | UNION NUT |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 338. | [1] | 131002-3800 | ADAPTOR |

| 339. | [2] | 029341-2140 | GASKET |

| 340. | [1] | 029711-2350 | INLET UNION |

| 341. | [1] | 029731-2240 | EYE BOLT |

| 411. | [1] | 154370-2620 | BRACKET |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105448-9710

F 019 Z1F 226

GOVERNOR

* K

* K

Information:

Introduction

There have been instances of issues with DEF pumps. After analysis, the cause of the issues has been found as contamination with hydrocarbons.Note: Diesel fuel is an example of a hydrocarbon.The DEF filter is equipped with a compensator located in the center of the filter assembly. If the compensator comes into contact with hydrocarbons, the compensator will swell and is designed to block the filter assembly and protect the DEF pump.Solution

The following procedure is designed to diagnose if the DEF pump has been contaminated with hydrocarbons.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Ensure that the engine is stopped before any servicing or repair is performed. The Diesel Exhaust Fluid (DEF) system must have completed a proper shutdown. Service on the DEF pump prior to completion of a proper shutdown can result in DEF spray and spillage.

Do not turn off the battery disconnect switch until the indicator lamp has turned off. If the switch is turned off when the indicator lamp is illuminated, the Diesel Exhaust Fluid (DEF) system may not shut down properly. If the DEF system does not shut down properly, DEF could freeze and damage the pump and lines.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Cat Dealer Service Tool Catalog" or refer to Special Publication, PECJ0003, "Cat Shop Supplies and Tools Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.Dispose of all fluids according to local regulations and mandates.

Note: Clean water should be used to wash spilled DEF off machine components and surfaces.Note: Wear gloves when handling the DEF filter.

Illustration 1 g06278274

(1) Protective cover

Remove protective cover (1).

Illustration 2 g06278289

(2) DEF filter cap

Use a suitable tool to remove DEF filter cap (2).

Illustration 3 g06278325

(3) Compensator

With the filter installed in the DEF pump, carefully remove compensator (3).

Illustration 4 g06614423

(A) 85 mm (3.3 inch)

(B) 17 mm (0.7 inch)

Check the measurements of compensator (3). Check if the measurements are greater than specified in Illustration 4. This condition indicates that the DEF pump is contaminated with hydrocarbons.

If the measurements indicate contamination, replace the DEF pump filter. Refer to Operation and Maintenance Manual, Diesel Exhaust Fluid Filter - Replace.Flush the DEF tank. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Tank - Flush.

If the measurements are within the specification, continue to follow the appropriate troubleshooting procedure to determine if the DEF pump has a fault.

There have been instances of issues with DEF pumps. After analysis, the cause of the issues has been found as contamination with hydrocarbons.Note: Diesel fuel is an example of a hydrocarbon.The DEF filter is equipped with a compensator located in the center of the filter assembly. If the compensator comes into contact with hydrocarbons, the compensator will swell and is designed to block the filter assembly and protect the DEF pump.Solution

The following procedure is designed to diagnose if the DEF pump has been contaminated with hydrocarbons.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Ensure that the engine is stopped before any servicing or repair is performed. The Diesel Exhaust Fluid (DEF) system must have completed a proper shutdown. Service on the DEF pump prior to completion of a proper shutdown can result in DEF spray and spillage.

Do not turn off the battery disconnect switch until the indicator lamp has turned off. If the switch is turned off when the indicator lamp is illuminated, the Diesel Exhaust Fluid (DEF) system may not shut down properly. If the DEF system does not shut down properly, DEF could freeze and damage the pump and lines.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Cat Dealer Service Tool Catalog" or refer to Special Publication, PECJ0003, "Cat Shop Supplies and Tools Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.Dispose of all fluids according to local regulations and mandates.

Note: Clean water should be used to wash spilled DEF off machine components and surfaces.Note: Wear gloves when handling the DEF filter.

Illustration 1 g06278274

(1) Protective cover

Remove protective cover (1).

Illustration 2 g06278289

(2) DEF filter cap

Use a suitable tool to remove DEF filter cap (2).

Illustration 3 g06278325

(3) Compensator

With the filter installed in the DEF pump, carefully remove compensator (3).

Illustration 4 g06614423

(A) 85 mm (3.3 inch)

(B) 17 mm (0.7 inch)

Check the measurements of compensator (3). Check if the measurements are greater than specified in Illustration 4. This condition indicates that the DEF pump is contaminated with hydrocarbons.

If the measurements indicate contamination, replace the DEF pump filter. Refer to Operation and Maintenance Manual, Diesel Exhaust Fluid Filter - Replace.Flush the DEF tank. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Tank - Flush.

If the measurements are within the specification, continue to follow the appropriate troubleshooting procedure to determine if the DEF pump has a fault.

Have questions with 105448-9710?

Group cross 105448-9710 ZEXEL

105448-9710

F 019 Z1F 226

GOVERNOR