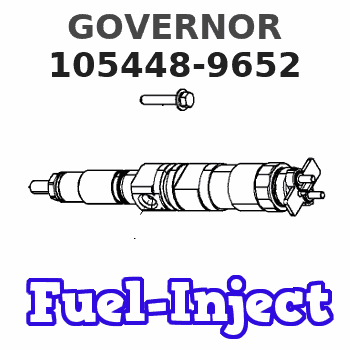

Information governor

BOSCH

9 420 613 240

9420613240

ZEXEL

105448-9652

1054489652

Rating:

Scheme ###:

| 1. | [1] | 154002-2920 | GOVERNOR HOUSING |

| 5. | [1] | 154007-1600 | CAPSULE |

| 8. | [9] | 029300-6040 | PLAIN WASHER D11&6.4T1 |

| 9. | [9] | 029320-6010 | LOCKING WASHER |

| 10. | [9] | 029000-6490 | BLEEDER SCREW M6P1.0L23 |

| 12. | [1] | 154010-3900 | BLEEDER SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154520-2420 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0200 | BUSHING |

| 38. | [1] | 154031-3000 | FLAT-HEAD SCREW |

| 39. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [4] | 029000-6470 | BLEEDER SCREW |

| 52. | [5] | 029000-6480 | BLEEDER SCREW M6P1.0L35 |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 55. | [9] | 029320-6010 | LOCKING WASHER |

| 55. | [9] | 029320-6010 | LOCKING WASHER |

| 56. | [9] | 029300-6040 | PLAIN WASHER D11&6.4T1 |

| 56. | [9] | 029300-6040 | PLAIN WASHER D11&6.4T1 |

| 65. | [1] | 153020-3920 | STOPPING DEVICE |

| 66. | [1] | 029332-0050 | GASKET |

| 80. | [1] | 154063-0900 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 029020-6210 | BLEEDER SCREW |

| 100. | [1] | 154100-9720 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 104. | [1] | 154120-0100 | PLAIN WASHER |

| 106. | [1] | 029602-0020 | LOCKING WASHER |

| 107. | [1] | 154121-0400 | TOOTHED GEAR |

| 108. | [1] | 016610-2640 | BEARING PLATE |

| 109. | [1] | 028102-0010 | BEARING PLATE |

| 111. | [1] | 154134-0000 | SPACER BUSHING |

| 112. | [1] | 154122-0300 | COVER |

| 113. | [1] | 029614-7020 | LOCKING WASHER |

| 114. | [1] | 025803-1610 | WOODRUFF KEY |

| 115. | [1] | 029321-2020 | LOCKING WASHER |

| 116. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-1920 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 119. | [1] | 154130-1720 | TOOTHED GEAR |

| 119/3. | [4] | 153251-0100 | DAMPER |

| 119/4. | [1] | 139329-0000 | PLAIN WASHER |

| 119/5. | [1] | 016020-2810 | LOCKING WASHER |

| 122. | [3] | 020106-2840 | BLEEDER SCREW |

| 132. | [1] | 154154-2900 | COILED SPRING |

| 133. | [2] | 154156-0100 | TUBE |

| 134. | [1] | 154158-0620 | HEADLESS SCREW |

| 136. | [1] | 029201-2290 | UNION NUT |

| 137. | [2] | 026512-1640 | GASKET D15.9&12.2T1 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154185-3120 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-4520 | SWIVELLING LEVER |

| 151. | [1] | 154204-2100 | BUSHING |

| 152. | [2] | 139716-0100 | O-RING |

| 152. | [2] | 139716-0100 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0200 | PACKING RING |

| 155. | [1] | 029311-1010 | SHIM |

| 158. | [1] | 154204-2200 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 170. | [1] | 154211-5220 | FORK LEVER |

| 174. | [1] | 154230-1820 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 176. | [1] | 154232-0500 | CONNECTOR |

| 177. | [1] | 154316-2300 | BLEEDER SCREW |

| 178. | [1] | 029320-6010 | LOCKING WASHER |

| 181. | [1] | 154236-5821 | TENSIONING LEVER |

| 182. | [1] | 154237-0200 | BEARING PIN |

| 190. | [1] | 154347-4423 | CONTROL LEVER |

| 191. | [1] | 154365-4300 | CONTROL LEVER |

| 192. | [1] | 020006-2070 | BLEEDER SCREW M6P1L20 7T |

| 201. | [1] | 139710-0400 | O-RING |

| 207. | [1] | 154326-5020 | CONTROL LEVER |

| 211. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 211B. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 236. | [1] | 154390-2900 | GASKET |

| 237. | [1] | 154390-3100 | GASKET |

| 238. | [1] | 154390-3500 | GASKET |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 338. | [1] | 131002-3800 | ADAPTOR |

| 339. | [2] | 029341-2140 | GASKET |

| 340. | [1] | 154373-1800 | INLET UNION |

| 341. | [1] | 154373-1700 | EYE BOLT |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Fuel Injectors in 797F powered Off-Highway Trucks engines are not reaching expected mid-life target. The typical failure mode is a "-2" or a "-7" code on the fuel injectors.Solution

This will be an interim troubleshooting procedure to follow for trucks running with a special test software. Prior to executing this procedure, utilize Cat ® Electronic Technician (Cat ET) or Advisor to verify if any logged codes have been logged. Certain injector diagnostics do not notify the operator or light the check engine light upon activation."Fuel system verification-Test" procedure applies to trucks running with following software versions only.

Engine - LRC 3655600-31 (Test)

Engine - Tier II 5297866-05 (Test)

Engine - HAA (4x2) 3253178-39 (Test)

Engine - Tier II Custom 4727209-12 (Test)Troubleshooting Procedure

Table 1

Troubleshooting Test Steps Values Results

1. Check for Diagnostic Codes

A. Establish communication between Cat® (Electronic Technician) ET and the engine ECM. Cat ET must be configured for Dual Data Link Communications to perform this procedure. Refer to Troubleshooting, "Electronic Service Tools", if necessary.

B. Determine the diagnostic code that relates to an injector. Codes

Result: A -2 code is present.

Repair: Perform the following procedure:

1. Do not clear the diagnostic code.

Access the Fuel System Verification Test by accessing the following display screens:

- Diagnostics

- Diagnostic Tests

- Fuel System Verification Test

3. Perform the Fuel System Verification Test.

If the injector passes the test, the injector is "OK". Cat ET will clear the code.

Result: If the injector fails the test, perform the following procedure:

a. Replace the injector.

b. Flash program the trim file for the new injector into the ECM. Refer to Troubleshooting, "Injector Trim File - Install", if necessary.

c. Perform the Fuel System Verification Test again. This test will clear the active diagnostic code for the new injector. Verify that the original condition has been resolved.

Result: If the test

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Fuel Injectors in 797F powered Off-Highway Trucks engines are not reaching expected mid-life target. The typical failure mode is a "-2" or a "-7" code on the fuel injectors.Solution

This will be an interim troubleshooting procedure to follow for trucks running with a special test software. Prior to executing this procedure, utilize Cat ® Electronic Technician (Cat ET) or Advisor to verify if any logged codes have been logged. Certain injector diagnostics do not notify the operator or light the check engine light upon activation."Fuel system verification-Test" procedure applies to trucks running with following software versions only.

Engine - LRC 3655600-31 (Test)

Engine - Tier II 5297866-05 (Test)

Engine - HAA (4x2) 3253178-39 (Test)

Engine - Tier II Custom 4727209-12 (Test)Troubleshooting Procedure

Table 1

Troubleshooting Test Steps Values Results

1. Check for Diagnostic Codes

A. Establish communication between Cat® (Electronic Technician) ET and the engine ECM. Cat ET must be configured for Dual Data Link Communications to perform this procedure. Refer to Troubleshooting, "Electronic Service Tools", if necessary.

B. Determine the diagnostic code that relates to an injector. Codes

Result: A -2 code is present.

Repair: Perform the following procedure:

1. Do not clear the diagnostic code.

Access the Fuel System Verification Test by accessing the following display screens:

- Diagnostics

- Diagnostic Tests

- Fuel System Verification Test

3. Perform the Fuel System Verification Test.

If the injector passes the test, the injector is "OK". Cat ET will clear the code.

Result: If the injector fails the test, perform the following procedure:

a. Replace the injector.

b. Flash program the trim file for the new injector into the ECM. Refer to Troubleshooting, "Injector Trim File - Install", if necessary.

c. Perform the Fuel System Verification Test again. This test will clear the active diagnostic code for the new injector. Verify that the original condition has been resolved.

Result: If the test