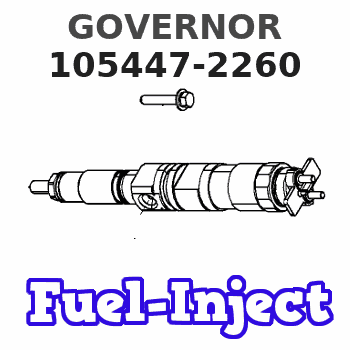

Information governor

BOSCH

F 019 Z4E 085

f019z4e085

ZEXEL

105447-2260

1054472260

Rating:

Scheme ###:

| 1. | [1] | 154002-4620 | GOVERNOR HOUSING |

| 5. | [1] | 154007-1600 | CAPSULE |

| 10. | [8] | 139006-4100 | BLEEDER SCREW |

| 12. | [1] | 154010-3900 | BLEEDER SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 15. | [2] | 139608-0200 | PACKING RING |

| 16. | [1] | 155004-4900 | LEVER SHAFT |

| 18. | [1] | 155003-3100 | CONTROL LEVER |

| 19. | [1] | 155006-0700 | BLEEDER SCREW |

| 20. | [1] | 139308-1100 | PLAIN WASHER |

| 21. | [0] | 029310-8050 | SHIM D13.5&8T0.5 |

| 21. | [0] | 029310-8050 | SHIM D13.5&8T0.5 |

| 22. | [0] | 029310-8050 | SHIM D13.5&8T0.5 |

| 23. | [1] | 155402-3800 | SAFETY PIN |

| 24. | [1] | 154206-2000 | BUSHING |

| 25. | [1] | 154327-3600 | COILED SPRING |

| 26. | [1] | 154367-5300 | CONTROL LEVER |

| 27. | [1] | 014110-8440 | LOCKING WASHER |

| 28. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 35. | [1] | 154520-7220 | GOVERNOR COVER |

| 38. | [1] | 154031-3000 | FLAT-HEAD SCREW |

| 39. | [1] | 139206-0600 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [4] | 020106-5040 | BLEEDER SCREW |

| 52. | [3] | 020106-2840 | BLEEDER SCREW |

| 53. | [1] | 154010-0300 | FLAT-HEAD SCREW |

| 80. | [1] | 154063-8200 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154101-4620 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 104. | [1] | 154120-0100 | PLAIN WASHER |

| 106. | [1] | 029602-0020 | LOCKING WASHER |

| 107. | [1] | 154121-0500 | TOOTHED GEAR |

| 108. | [1] | 016610-2640 | BEARING PLATE |

| 109. | [1] | 028102-0010 | BEARING PLATE |

| 111. | [1] | 154134-0000 | SPACER BUSHING |

| 112. | [1] | 154122-0300 | COVER |

| 113. | [1] | 029614-7020 | LOCKING WASHER |

| 114. | [1] | 025803-1310 | WOODRUFF KEY |

| 115. | [1] | 029321-2020 | LOCKING WASHER |

| 116. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-1020 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 119. | [1] | 154130-1820 | TOOTHED GEAR |

| 119/2. | [1] | 154132-0320 | HOLDER |

| 119/3. | [4] | 153251-0100 | DAMPER |

| 119/4. | [1] | 139329-0000 | PLAIN WASHER |

| 119/5. | [1] | 016020-2810 | LOCKING WASHER |

| 122. | [3] | 020106-2840 | BLEEDER SCREW |

| 132. | [1] | 154154-3900 | COILED SPRING |

| 133. | [2] | 154156-0100 | TUBE |

| 135. | [1] | 154158-0620 | HEADLESS SCREW |

| 136. | [1] | 029201-2290 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154185-5620 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-4520 | SWIVELLING LEVER |

| 151. | [1] | 154204-4100 | BUSHING |

| 152. | [1] | 139718-0200 | O-RING |

| 152B. | [1] | 139716-0100 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0200 | PACKING RING |

| 155. | [1] | 029311-1010 | SHIM |

| 158. | [1] | 154204-2200 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 170. | [1] | 154211-5420 | FORK LEVER |

| 174. | [1] | 154234-9220 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 176. | [1] | 154232-2700 | CONNECTOR |

| 177. | [2] | 029050-5040 | FLAT-HEAD SCREW M5P0.8L9 |

| 181. | [1] | 154236-5821 | TENSIONING LEVER |

| 182. | [1] | 154237-0200 | BEARING PIN |

| 190. | [1] | 154347-4423 | CONTROL LEVER |

| 235. | [1] | 029621-7010 | PACKING RING |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154371-3500 | GASKET |

| 238. | [1] | 154390-3500 | GASKET |

| 300. | [1] | 154010-0200 | FLAT-HEAD SCREW |

| 301. | [1] | 154011-0100 | HEXAGON NUT |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 338. | [1] | 131002-3800 | ADAPTOR |

| 339. | [2] | 029341-2140 | GASKET |

| 340. | [1] | 154373-1800 | INLET UNION |

| 341. | [1] | 154373-1700 | EYE BOLT |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Include in #1:

106685-4024

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

105447-2260

GOVERNOR

K 14JC MECHANICAL GOVERNOR GOV RSUV(D) GOV

K 14JC MECHANICAL GOVERNOR GOV RSUV(D) GOV

Information:

The Caterpillar Electronic Technician (ET)

Illustration 1 g00777826

The Caterpillar Electronic Technician (ET) is a software program that is used to access data. The service technician can use the Caterpillar Electronic Technician in order to perform maintenance work on the machine. Some of the options that are available with the Caterpillar Electronic Technician are listed below:

View Diagnostic codes. See Troubleshooting, "Using the Caterpillar Electronic Technician to Determine Diagnostic Codes".

View the status of parameters.

Clear active diagnostic codes and clear logged diagnostic codes

Perform calibration of machine systems.

Program the ECM (Flash). This is done with the "WINflash" program. See Testing and Adjusting, "Electronic Control Module (ECM) - Flash Program".

Print reports.The following list contains some of the diagnostic functions and programming functions that are performed by the service tools.

The failures of the ECM system are displayed.

The status of most of the inputs and the outputs are displayed.

The settings for the ECM are displayed.

Display the status of the input and output parameters in real time.

Display the clock hour of the internal diagnostic clock.

The number of occurrences and the clock hour of the first occurrence and the last occurrence is displayed for each logged diagnostic code.

The definition for each logged diagnostic code and each event is displayed.

Load new FLASH software.See Troubleshooting, "Diagnostic Code List" for the list of diagnostic codes for the ECM.See Troubleshooting, "Using the Caterpillar Electronic Technician to Determine Diagnostic Codes". Diagnostic information is accessed with the following drop down menus:

Active diagnostic codes

Logged diagnostic codesSensor Diagnostics

The following tables show the conditions that the diagnostic codes are set for each sensor. If any of the diagnostic codes are active, the System Problem for the LED will be turned on. During the Debounce time, the affected parameter will remain at the last good value. After the Debounce time, the affected parameter will be set to the default value. Refer to Table 1.

Table 1

Sensor Sample Period (mS) Too Low Too High Defaults

Inlet Pressure (gauge) Code Condition Debounce Code Condition Debounce NA

1 81-4 Input < 0.5 VDC 5 sec on

5 sec off 81-3 Input greater than 4.5 VDC 5 sec on

5 sec off NA

Exhaust Temperature 1 535-4 Input < 1.5 VDC 5 sec on

5 sec off 535-3 Input greater than 4.0 VDC 5 sec on

5 sec off NA Temperature Sensor

Table 2 refers to the properties of the temperature sensor.

Table 2

Function Part Number Measure Range Output Accuracy Power Supply Sensor Mounting Mating

Exhaust Temperature 280-3921

50 °C (122 °F)to

850 °C (1562 °F) N/A

500° 5°C (932° 9°F) to

850° 5°C (1562° 9°F) 5V (+/- 0.5) Thread Size: M14 X 1.5

Probe Length:

70 mm (2.7559 inch) from flange to tip 230-5008 Connector Plug As Pressure Sensor

Table 3

Function PN Max Pressure Measure Burst Pressure Power

Illustration 1 g00777826

The Caterpillar Electronic Technician (ET) is a software program that is used to access data. The service technician can use the Caterpillar Electronic Technician in order to perform maintenance work on the machine. Some of the options that are available with the Caterpillar Electronic Technician are listed below:

View Diagnostic codes. See Troubleshooting, "Using the Caterpillar Electronic Technician to Determine Diagnostic Codes".

View the status of parameters.

Clear active diagnostic codes and clear logged diagnostic codes

Perform calibration of machine systems.

Program the ECM (Flash). This is done with the "WINflash" program. See Testing and Adjusting, "Electronic Control Module (ECM) - Flash Program".

Print reports.The following list contains some of the diagnostic functions and programming functions that are performed by the service tools.

The failures of the ECM system are displayed.

The status of most of the inputs and the outputs are displayed.

The settings for the ECM are displayed.

Display the status of the input and output parameters in real time.

Display the clock hour of the internal diagnostic clock.

The number of occurrences and the clock hour of the first occurrence and the last occurrence is displayed for each logged diagnostic code.

The definition for each logged diagnostic code and each event is displayed.

Load new FLASH software.See Troubleshooting, "Diagnostic Code List" for the list of diagnostic codes for the ECM.See Troubleshooting, "Using the Caterpillar Electronic Technician to Determine Diagnostic Codes". Diagnostic information is accessed with the following drop down menus:

Active diagnostic codes

Logged diagnostic codesSensor Diagnostics

The following tables show the conditions that the diagnostic codes are set for each sensor. If any of the diagnostic codes are active, the System Problem for the LED will be turned on. During the Debounce time, the affected parameter will remain at the last good value. After the Debounce time, the affected parameter will be set to the default value. Refer to Table 1.

Table 1

Sensor Sample Period (mS) Too Low Too High Defaults

Inlet Pressure (gauge) Code Condition Debounce Code Condition Debounce NA

1 81-4 Input < 0.5 VDC 5 sec on

5 sec off 81-3 Input greater than 4.5 VDC 5 sec on

5 sec off NA

Exhaust Temperature 1 535-4 Input < 1.5 VDC 5 sec on

5 sec off 535-3 Input greater than 4.0 VDC 5 sec on

5 sec off NA Temperature Sensor

Table 2 refers to the properties of the temperature sensor.

Table 2

Function Part Number Measure Range Output Accuracy Power Supply Sensor Mounting Mating

Exhaust Temperature 280-3921

50 °C (122 °F)to

850 °C (1562 °F) N/A

500° 5°C (932° 9°F) to

850° 5°C (1562° 9°F) 5V (+/- 0.5) Thread Size: M14 X 1.5

Probe Length:

70 mm (2.7559 inch) from flange to tip 230-5008 Connector Plug As Pressure Sensor

Table 3

Function PN Max Pressure Measure Burst Pressure Power