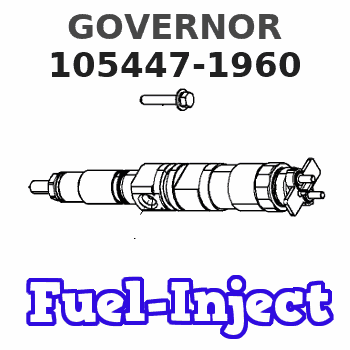

Information governor

BOSCH

9 420 611 621

9420611621

ZEXEL

105447-1960

1054471960

Rating:

Scheme ###:

| 1. | [1] | 154002-3320 | GOVERNOR HOUSING |

| 5. | [1] | 154007-1600 | CAPSULE |

| 10. | [8] | 139006-4100 | BLEEDER SCREW |

| 12. | [1] | 154010-3900 | BLEEDER SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154520-8320 | GOVERNOR COVER |

| 35/1. | [1] | 154520-8300 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0200 | BUSHING |

| 38. | [1] | 154031-3800 | FLAT-HEAD SCREW |

| 39. | [1] | 139206-0600 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [4] | 020106-5040 | BLEEDER SCREW |

| 52. | [3] | 020106-2840 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 65. | [1] | 153021-2220 | STOPPING DEVICE |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154063-0900 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154100-9720 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 104. | [1] | 154120-0100 | PLAIN WASHER |

| 106. | [1] | 029602-0020 | LOCKING WASHER |

| 107. | [1] | 154121-0500 | TOOTHED GEAR |

| 108. | [1] | 016610-2640 | BEARING PLATE |

| 109. | [1] | 028102-0010 | BEARING PLATE |

| 111. | [1] | 154134-0000 | SPACER BUSHING |

| 112. | [1] | 154122-0300 | COVER |

| 113. | [1] | 029614-7020 | LOCKING WASHER |

| 114. | [1] | 025803-1310 | WOODRUFF KEY |

| 115. | [1] | 029321-2020 | LOCKING WASHER |

| 116. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-1020 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 119. | [1] | 154130-1820 | TOOTHED GEAR |

| 119/2. | [1] | 154132-0320 | HOLDER |

| 119/3. | [4] | 153251-0100 | DAMPER |

| 119/4. | [1] | 139329-0000 | PLAIN WASHER |

| 119/5. | [1] | 016020-2810 | LOCKING WASHER |

| 122. | [3] | 020106-2840 | BLEEDER SCREW |

| 132. | [1] | 154154-0900 | COILED SPRING |

| 133. | [2] | 154156-0100 | TUBE |

| 135. | [1] | 154158-3620 | HEADLESS SCREW |

| 136. | [1] | 029201-2140 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 150. | [1] | 154200-4520 | SWIVELLING LEVER |

| 151. | [1] | 154204-4100 | BUSHING |

| 152. | [1] | 139718-0200 | O-RING |

| 152B. | [1] | 139716-0100 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0200 | PACKING RING |

| 155. | [1] | 029311-1010 | SHIM |

| 158. | [1] | 154204-2200 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 170. | [1] | 154211-5420 | FORK LEVER |

| 174. | [1] | 154230-0220 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 176. | [1] | 154232-0400 | CONNECTOR |

| 177. | [2] | 029050-5040 | FLAT-HEAD SCREW M5P0.8L9 |

| 181. | [1] | 154239-3920 | TENSIONING LEVER |

| 182. | [1] | 154237-0200 | BEARING PIN |

| 190. | [1] | 154395-9020 | CONTROL LEVER |

| 191. | [1] | 154304-4720 | CONTROL LEVER |

| 192. | [1] | 020006-1670 | BLEEDER SCREW M6P1L16 7T |

| 201. | [1] | 139710-0400 | O-RING |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5120 | CONTROL LEVER |

| 208. | [1] | 154327-7300 | COILED SPRING |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154371-3500 | GASKET |

| 238. | [1] | 154390-3500 | GASKET |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 338. | [1] | 131002-3800 | ADAPTOR |

| 339. | [2] | 029341-2140 | GASKET |

| 340. | [1] | 154373-1800 | INLET UNION |

| 341. | [1] | 154373-1700 | EYE BOLT |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Include in #1:

106682-9500

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Table 1

S O S Oil Sampling Interval for Engine crankcase

Recommended Interval (1)(2) Oil Type

Every 250 Service Hours Cat DEO

Cat DEO-ULS

(1) Severe applications may require a more frequent oil sampling interval.

(2) Under certain conditions, the Cat dealer or the Operation and Maintenance Manual may allow a longer interval between oil samplings.Note: Refer to the Operation and Maintenance Manual for your engine for recommended oil drain intervals.Consult your Cat dealer for complete information and assistance in order to establish an S O S Services program for your engine.More Frequent S O S Sampling Improves Life Cycle Management

Traditionally, the suggested S O S sampling intervals for diesel engines have been at 250 hours. However in severe applications, more frequent oil sampling is recommended. Severe service for lubricated compartments occurs at high loads, in high temperatures, and in dusty conditions. If any of these conditions or other severe service indicators exist, sample the engine oil at 125 hour intervals. These additional samples will increase the chance of detecting a potential failure.Determining Optimum Oil Change Intervals

Sampling the engine oil at every 125 hours provides information for oil condition and for oil performance. This information is used to determine the optimum usable life of a particular oil. Also, more points of data will allow closer monitoring of component wear rates. Close monitoring also allows you to obtain the maximum use of the oil. For detailed information on optimizing oil change intervals, consult your Cat dealer.This Special Publication does not address recommended oil drain intervals. Refer to your engine Operation and Maintenance Manual, and consult your Cat dealer for additional guidance, including but not limited to guidance on establishing optimized and/or acceptable oil drain intervals.To reduce the potential risk of failures associated with extended oil drain periods, Caterpillar recommends that oil drain intervals only be extended based on oil analysis, and subsequent system inspections. Oil analysis alone does not provide an indication of the rate of formation of lacquer, varnish and/or other deposits on surfaces. The only accurate way to evaluate specific oil performance in a specific system using extended oil drain periods is to observe the effects on the system components. Making these observations involves tear-down inspections of systems that have run to the normal overhaul period while using extended oil drain intervals. Following this recommendation will help ensure that excessive component wear does not take place in a given application.Note: The use of Cat S O S Services oil analysis helps environmental sustainability as the best way to optimize oil life. S O S Services will help engines reach expected life. Consult your Cat dealer regarding the testing required to establish a safe, optimized oil drain interval.Standard oil drain intervals as published in engine Operation and Maintenance Manual are for typical applications:

Using recommended oils

Using good fuel

Using recommended filters

Using industry standard good maintenance practices

Following maintenance intervals as published in engine Operation and Maintenance ManualMore severe applications may require shortened oil drain intervals, while less severe applications may allow for longer than standard oil drain intervals. High