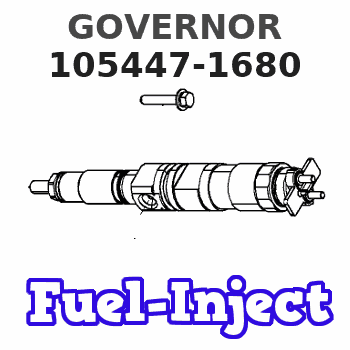

Information governor

BOSCH

9 420 610 791

9420610791

ZEXEL

105447-1680

1054471680

Rating:

Scheme ###:

| 1. | [1] | 154002-3320 | GOVERNOR HOUSING |

| 5. | [1] | 154007-1600 | CAPSULE |

| 10. | [8] | 139006-4100 | BLEEDER SCREW |

| 12. | [1] | 154010-3900 | BLEEDER SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154521-1220 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0200 | BUSHING |

| 38. | [1] | 154031-3800 | FLAT-HEAD SCREW |

| 39. | [1] | 139206-0600 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [4] | 020106-5040 | BLEEDER SCREW |

| 52. | [3] | 020106-2840 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 80. | [1] | 154063-0900 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154100-9720 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 104. | [1] | 154120-0100 | PLAIN WASHER |

| 106. | [1] | 029602-0020 | LOCKING WASHER |

| 107. | [1] | 154121-0400 | TOOTHED GEAR |

| 108. | [1] | 016610-2640 | BEARING PLATE |

| 109. | [1] | 028102-0010 | BEARING PLATE |

| 111. | [1] | 154134-0000 | SPACER BUSHING |

| 112. | [1] | 154122-0300 | COVER |

| 113. | [1] | 029614-7020 | LOCKING WASHER |

| 114. | [1] | 025803-1610 | WOODRUFF KEY |

| 115. | [1] | 029321-2020 | LOCKING WASHER |

| 116. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-1020 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 119. | [1] | 154130-1720 | TOOTHED GEAR |

| 119/3. | [4] | 153251-0100 | DAMPER |

| 119/4. | [1] | 139329-0000 | PLAIN WASHER |

| 119/5. | [1] | 016020-2810 | LOCKING WASHER |

| 122. | [3] | 020106-2840 | BLEEDER SCREW |

| 132. | [1] | 154154-2900 | COILED SPRING |

| 133. | [2] | 154156-0100 | TUBE |

| 135. | [1] | 154158-3320 | HEADLESS SCREW |

| 136. | [1] | 029201-2290 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 150. | [1] | 154200-7520 | SWIVELLING LEVER |

| 151. | [1] | 154204-4100 | BUSHING |

| 152. | [1] | 139718-0200 | O-RING |

| 152B. | [1] | 139716-0100 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0200 | PACKING RING |

| 155. | [1] | 029311-1010 | SHIM |

| 158. | [1] | 154204-2200 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 170. | [1] | 154211-5420 | FORK LEVER |

| 174. | [1] | 154230-0220 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 176. | [1] | 154232-0400 | CONNECTOR |

| 177. | [2] | 029050-5040 | FLAT-HEAD SCREW M5P0.8L9 |

| 181. | [1] | 154239-3920 | TENSIONING LEVER |

| 182. | [1] | 154237-0200 | BEARING PIN |

| 190. | [1] | 154395-0520 | CONTROL LEVER |

| 191. | [1] | 154381-5000 | CONTROL LEVER |

| 192. | [1] | 020006-2070 | BLEEDER SCREW M6P1L20 7T |

| 201. | [1] | 139710-0400 | O-RING |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5120 | CONTROL LEVER |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154371-3500 | GASKET |

| 238. | [1] | 154390-3500 | GASKET |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 338. | [1] | 131002-3800 | ADAPTOR |

| 339. | [2] | 029341-2140 | GASKET |

| 340. | [1] | 154373-1800 | INLET UNION |

| 341. | [1] | 154373-1700 | EYE BOLT |

| 400. | [2] | 020006-1470 | BLEEDER SCREW M6P1L14 7T |

| 401. | [1] | 154381-5100 | CONTROL LEVER |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Starting Aids

The use of a starting aid is a conventional method of assistance for cold starts in low temperature conditions. A variety of starting aids are available for Caterpillar engines. Follow the recommendations that are provided by the manufacturer of the starting aid.Engine Coolant Heaters

These heaters heat the engine coolant. The heated coolant flows through the cylinder block. The flow of heated coolant keeps the engine warm. A warm engine is easier to start in cold weather. Most coolant heaters use electrical power. A source of electricity is necessary for this type of heater. Other heaters that burn fuel are available as a source of heat. These heaters may be used in place of the electrical heaters.With either type of heater, starting aids and/or fuels with higher cetane numbers are less important because the engine is warm. Problems with fuel cloud point can cause the plugging of fuel filters. Problems with fuel cloud point cannot be corrected by engine coolant heaters. This is especially true for fuel filters that are cooled by air flow during operation.Fuel Heaters

A thermostatically controlled fuel heater can be installed when the use of No. 2 diesel in the winter cannot be avoided. Fuel heaters can help prevent fuel filters from plugging due to waxing and the formation of ice crystals from excessive water. A fuel heater is not effective for cold starts unless the fuel heater can be powered by an external power source. The fuel heater should be connected to the power source while the engine is not operating. A fuel heater can be installed in order to heat the fuel before the fuel enters the primary fuel filter. Select a fuel heater that is mechanically simple, yet adequate for the application. Choose a fuel heater with a large heating surface that is practical. Small heaters can be too hot because of the limited surface area.Note: Heat exchanger type fuel heaters should have a bypass provision to prevent excessive heating of the fuel in warm weather operation. The excessive heating of the fuel will cause a loss of engine power. The maximum temperature of the fuel that is allowed for electronic engines can be found in the Operation and Maintenance Manual. Thermostatically controlled fuel heaters may be required for electronic engines. The following fuel heaters are available for use with Caterpillar engines, including PEEC engines and Electronic engines.

7C-3557 Fuel Heater Gp

7C-3558 Heater Kit Disconnect the fuel heater or deactivate the fuel heater in warm weather in order to prevent excessive heating of fuel and possible engine power loss. A gradual loss of engine power occurs as the fuel supply temperature increases. An electronic engine will self-adjust for higher fuel temperatures to a limit. See your Caterpillar dealer for information. De-Icers

De-icers lower the freezing point of the moisture in the fuel. De-icers are not generally needed when fuel heaters are used. If you experience trouble, consult your fuel supplier for recommendations of a compatible commercial de-icer.Fuel Tanks

Fuel tanks should contain some provision

The use of a starting aid is a conventional method of assistance for cold starts in low temperature conditions. A variety of starting aids are available for Caterpillar engines. Follow the recommendations that are provided by the manufacturer of the starting aid.Engine Coolant Heaters

These heaters heat the engine coolant. The heated coolant flows through the cylinder block. The flow of heated coolant keeps the engine warm. A warm engine is easier to start in cold weather. Most coolant heaters use electrical power. A source of electricity is necessary for this type of heater. Other heaters that burn fuel are available as a source of heat. These heaters may be used in place of the electrical heaters.With either type of heater, starting aids and/or fuels with higher cetane numbers are less important because the engine is warm. Problems with fuel cloud point can cause the plugging of fuel filters. Problems with fuel cloud point cannot be corrected by engine coolant heaters. This is especially true for fuel filters that are cooled by air flow during operation.Fuel Heaters

A thermostatically controlled fuel heater can be installed when the use of No. 2 diesel in the winter cannot be avoided. Fuel heaters can help prevent fuel filters from plugging due to waxing and the formation of ice crystals from excessive water. A fuel heater is not effective for cold starts unless the fuel heater can be powered by an external power source. The fuel heater should be connected to the power source while the engine is not operating. A fuel heater can be installed in order to heat the fuel before the fuel enters the primary fuel filter. Select a fuel heater that is mechanically simple, yet adequate for the application. Choose a fuel heater with a large heating surface that is practical. Small heaters can be too hot because of the limited surface area.Note: Heat exchanger type fuel heaters should have a bypass provision to prevent excessive heating of the fuel in warm weather operation. The excessive heating of the fuel will cause a loss of engine power. The maximum temperature of the fuel that is allowed for electronic engines can be found in the Operation and Maintenance Manual. Thermostatically controlled fuel heaters may be required for electronic engines. The following fuel heaters are available for use with Caterpillar engines, including PEEC engines and Electronic engines.

7C-3557 Fuel Heater Gp

7C-3558 Heater Kit Disconnect the fuel heater or deactivate the fuel heater in warm weather in order to prevent excessive heating of fuel and possible engine power loss. A gradual loss of engine power occurs as the fuel supply temperature increases. An electronic engine will self-adjust for higher fuel temperatures to a limit. See your Caterpillar dealer for information. De-Icers

De-icers lower the freezing point of the moisture in the fuel. De-icers are not generally needed when fuel heaters are used. If you experience trouble, consult your fuel supplier for recommendations of a compatible commercial de-icer.Fuel Tanks

Fuel tanks should contain some provision