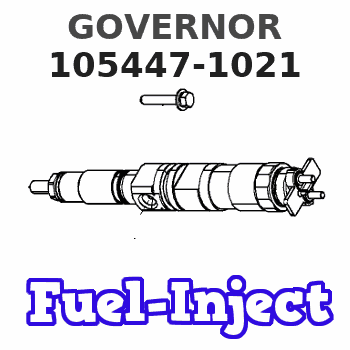

Information governor

BOSCH

9 420 610 783

9420610783

ZEXEL

105447-1021

1054471021

Rating:

Scheme ###:

| 1. | [1] | 154002-3520 | GOVERNOR HOUSING |

| 5. | [1] | 154007-1600 | CAPSULE |

| 10. | [8] | 139006-4100 | BLEEDER SCREW |

| 12. | [1] | 154010-3900 | BLEEDER SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 15. | [2] | 139608-0200 | PACKING RING |

| 15. | [2] | 139608-0200 | PACKING RING |

| 16. | [1] | 155004-4900 | LEVER SHAFT |

| 18. | [1] | 155003-3100 | CONTROL LEVER |

| 19. | [1] | 155006-0700 | BLEEDER SCREW |

| 20. | [1] | 139308-1100 | PLAIN WASHER |

| 21. | [0] | 029310-8050 | SHIM D13.5&8T0.5 |

| 22. | [0] | 029310-8050 | SHIM D13.5&8T0.5 |

| 22. | [0] | 029310-8050 | SHIM D13.5&8T0.5 |

| 23. | [1] | 155402-3800 | SAFETY PIN |

| 24. | [1] | 154206-2000 | BUSHING |

| 25. | [1] | 154327-3600 | COILED SPRING |

| 26. | [1] | 154367-5300 | CONTROL LEVER |

| 27. | [1] | 014110-8440 | LOCKING WASHER |

| 28. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 35. | [1] | 154520-6920 | GOVERNOR COVER |

| 38. | [1] | 154031-3000 | FLAT-HEAD SCREW |

| 39. | [1] | 139206-0600 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [4] | 020106-5040 | BLEEDER SCREW |

| 52. | [3] | 020106-2840 | BLEEDER SCREW |

| 53. | [1] | 154010-0200 | FLAT-HEAD SCREW |

| 80. | [1] | 154063-9900 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 029020-6210 | BLEEDER SCREW |

| 100. | [1] | 154100-9720 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 104. | [1] | 154120-0100 | PLAIN WASHER |

| 106. | [1] | 029602-0020 | LOCKING WASHER |

| 107. | [1] | 154121-0500 | TOOTHED GEAR |

| 108. | [1] | 016610-2640 | BEARING PLATE |

| 109. | [1] | 028102-0010 | BEARING PLATE |

| 111. | [1] | 154134-0000 | SPACER BUSHING |

| 112. | [1] | 154122-0300 | COVER |

| 113. | [1] | 029614-7020 | LOCKING WASHER |

| 114. | [1] | 025803-1610 | WOODRUFF KEY |

| 115. | [1] | 029321-2020 | LOCKING WASHER |

| 116. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-1020 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 119. | [1] | 154130-1820 | TOOTHED GEAR |

| 119/3. | [4] | 153251-0100 | DAMPER |

| 119/4. | [1] | 139329-0000 | PLAIN WASHER |

| 119/5. | [1] | 016020-2810 | LOCKING WASHER |

| 122. | [3] | 020106-2840 | BLEEDER SCREW |

| 132. | [1] | 154154-3900 | COILED SPRING |

| 133. | [2] | 154156-0100 | TUBE |

| 135. | [1] | 154158-3720 | HEADLESS SCREW |

| 136. | [1] | 154371-3400 | UNION NUT |

| 137. | [2] | 026520-2440 | GASKET D23.9&20.2T1 |

| 138. | [1] | 154159-2000 | CAP NUT |

| 140. | [1] | 154186-0220 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-6420 | SWIVELLING LEVER |

| 151. | [1] | 154204-4100 | BUSHING |

| 152. | [1] | 139718-0200 | O-RING |

| 152B. | [1] | 139716-0100 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0200 | PACKING RING |

| 155. | [1] | 029311-1010 | SHIM |

| 158. | [1] | 154204-2200 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 170. | [1] | 154217-2820 | FORK LEVER |

| 172. | [3] | 029310-5170 | SHIM D8&5.3T0.5 |

| 172. | [3] | 029310-5170 | SHIM D8&5.3T0.5 |

| 173. | [2] | 025520-1210 | SPLIT PIN |

| 173. | [2] | 025520-1210 | SPLIT PIN |

| 174. | [1] | 154234-9220 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 176. | [1] | 154232-2700 | CONNECTOR |

| 177. | [2] | 029050-5040 | FLAT-HEAD SCREW M5P0.8L9 |

| 181. | [1] | 154236-9620 | TENSIONING LEVER |

| 182. | [1] | 154237-0200 | BEARING PIN |

| 190. | [1] | 154349-1720 | CONTROL LEVER |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154371-3500 | GASKET |

| 238. | [1] | 154371-3600 | GASKET |

| 255. | [1] | 154400-7420 | DIAPHRAGM |

| 256. | [1] | 154400-4800 | STOP PIN |

| 257. | [2] | 029330-8050 | GASKET |

| 257. | [2] | 029330-8050 | GASKET |

| 259. | [1] | 154372-7200 | HEXAGON NUT |

| 260. | [1] | 154401-4420 | CONTROL LEVER |

| 261. | [1] | 154401-1020 | STRAP |

| 262. | [1] | 026510-1440 | GASKET D13.9&10.2T1 |

| 263. | [1] | 154401-4500 | BLEEDER SCREW |

| 264. | [1] | 016010-0540 | LOCKING WASHER |

| 265. | [1] | 154222-6200 | BEARING PIN |

| 266. | [1] | 029300-4010 | PLAIN WASHER |

| 267. | [1] | 154411-2100 | COILED SPRING |

| 268. | [1] | 154404-5000 | COVER |

| 269. | [2] | 020106-2240 | BLEEDER SCREW |

| 270. | [1] | 154034-1900 | FLAT-HEAD SCREW |

| 271. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 273. | [1] | 029731-0120 | EYE BOLT |

| 274. | [2] | 029341-0110 | GASKET |

| 275. | [0] | 029312-0180 | SHIM D25.5&20T0.5 |

| 275B. | [0] | 029312-0210 | SHIM D25.5&20T0.2 |

| 276. | [1] | 154035-1600 | CAP NUT |

| 277. | [1] | 029320-6010 | LOCKING WASHER |

| 278. | [2] | 154413-2600 | GASKET |

| 279. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 283. | [1] | 016010-0440 | LOCKING WASHER |

| 285. | [1] | 029010-6310 | BLEEDER SCREW |

| 300. | [1] | 154010-0300 | FLAT-HEAD SCREW |

| 301. | [1] | 154011-0100 | HEXAGON NUT |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 338. | [1] | 131002-3800 | ADAPTOR |

| 339. | [2] | 029341-2140 | GASKET |

| 340. | [1] | 154373-1800 | INLET UNION |

| 341. | [1] | 154373-1700 | EYE BOLT |

| 353. | [2] | 029310-9080 | SHIM D16&9T1.7 |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105447-1021

GOVERNOR

K 14JC MECHANICAL GOVERNOR GOV RSUV(D) GOV

K 14JC MECHANICAL GOVERNOR GOV RSUV(D) GOV

Information:

Self-Diagnostics

The electronic system has self-diagnostic capabilities. When a problem is detected, a fault indicator is illuminated on the front of the module. A panel of indicators is also located on the MECP.Module Fault Indicators

A fault should be immediately serviced. A fault indicator is illuminated when a problem exists. When the PLC has an active fault, find the appropriate procedure in the troubleshooting section.Operating Information that is Stored in the Programmable Logic Controller

The SLC 5/04 uses a battery in order to provide backup power to the C-MOS RAM.Programmable Logic Controller Chassis or Rack

The PLC chassis contains the following components:

Power Supply

CPU Module

Input Modules

Output Modules

User Defined ModulesThe system uses the Allen-Bradley SLC 500 series of PLC.Central Processing Unit

Illustration 1 g00562937

The SLC 5/04 processor includes a three-position keyswitch on the front panel. The key switches the system from the following three modes of operation: RUN, PROGRAM and REMOTEThe key can be removed in each of the three positions. The mode changes when the position of the key is switched from the RUN position. Do not substitute the keyswitch for a master control relay. Do not substitute the keyswitch for an emergency stop switch.RUN Position

The RUN position places the processor in the run mode. The processor conducts the following functions:

The processor scans the ladder program.

The processor executes the ladder program.

The processor monitors input devices.

The processor energizes the output devices.

The processor acts on the enabled I/O forces.You can only change the processor's mode with the keyswitch. Revising of the program cannot be performed when you are on-line."PROG" Position

The Program position places the processor in the program mode. The processor does not scan the program and the processor does not execute the program. The controller's outputs are de-energized.You can only change the processor's mode with the keyswitch. Revising of the program can be performed when you are on-line.When the keyswitch is in the program position, a qualified technician can use the programmer interface device in order to change the processor's mode.Remote Position

The remote position places the processor in the remote mode. You can only change the processor's mode with the keyswitch. Revising of the program can be performed when you are on-line.When the keyswitch is in the remote position, a qualified technician can use the programmer interface device in order to change the processor's mode.Processor's Fault Indicators

A fault should be immediately serviced. A fault indicator is illuminated when a problem exists. When the PLC has an active fault, find the appropriate procedure in the troubleshooting section.The Processor's Indicators

Six LED indicators are on the front of the CPU module. The indicators show the operating status of your processor. The indicators have the labels that are in the following list:"RUN", "FLT", "BATT", "FORCE", "DH+" and "RS232"Thermocouple Module

The thermocouple module contains diagnostic features that can identify sources of problems. The problems may occur during power up. The problems may occur during normal operation. Each channel can receive a signal from the sensors or from the analog input devices.

Illustration 2 g00562940

LED indicatorsResistance Temperature Detector Module

The RTD module contains diagnostic features that

The electronic system has self-diagnostic capabilities. When a problem is detected, a fault indicator is illuminated on the front of the module. A panel of indicators is also located on the MECP.Module Fault Indicators

A fault should be immediately serviced. A fault indicator is illuminated when a problem exists. When the PLC has an active fault, find the appropriate procedure in the troubleshooting section.Operating Information that is Stored in the Programmable Logic Controller

The SLC 5/04 uses a battery in order to provide backup power to the C-MOS RAM.Programmable Logic Controller Chassis or Rack

The PLC chassis contains the following components:

Power Supply

CPU Module

Input Modules

Output Modules

User Defined ModulesThe system uses the Allen-Bradley SLC 500 series of PLC.Central Processing Unit

Illustration 1 g00562937

The SLC 5/04 processor includes a three-position keyswitch on the front panel. The key switches the system from the following three modes of operation: RUN, PROGRAM and REMOTEThe key can be removed in each of the three positions. The mode changes when the position of the key is switched from the RUN position. Do not substitute the keyswitch for a master control relay. Do not substitute the keyswitch for an emergency stop switch.RUN Position

The RUN position places the processor in the run mode. The processor conducts the following functions:

The processor scans the ladder program.

The processor executes the ladder program.

The processor monitors input devices.

The processor energizes the output devices.

The processor acts on the enabled I/O forces.You can only change the processor's mode with the keyswitch. Revising of the program cannot be performed when you are on-line."PROG" Position

The Program position places the processor in the program mode. The processor does not scan the program and the processor does not execute the program. The controller's outputs are de-energized.You can only change the processor's mode with the keyswitch. Revising of the program can be performed when you are on-line.When the keyswitch is in the program position, a qualified technician can use the programmer interface device in order to change the processor's mode.Remote Position

The remote position places the processor in the remote mode. You can only change the processor's mode with the keyswitch. Revising of the program can be performed when you are on-line.When the keyswitch is in the remote position, a qualified technician can use the programmer interface device in order to change the processor's mode.Processor's Fault Indicators

A fault should be immediately serviced. A fault indicator is illuminated when a problem exists. When the PLC has an active fault, find the appropriate procedure in the troubleshooting section.The Processor's Indicators

Six LED indicators are on the front of the CPU module. The indicators show the operating status of your processor. The indicators have the labels that are in the following list:"RUN", "FLT", "BATT", "FORCE", "DH+" and "RS232"Thermocouple Module

The thermocouple module contains diagnostic features that can identify sources of problems. The problems may occur during power up. The problems may occur during normal operation. Each channel can receive a signal from the sensors or from the analog input devices.

Illustration 2 g00562940

LED indicatorsResistance Temperature Detector Module

The RTD module contains diagnostic features that