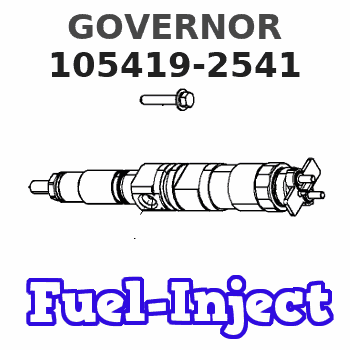

Information governor

BOSCH

9 420 611 709

9420611709

ZEXEL

105419-2541

1054192541

Rating:

Scheme ###:

| 1. | [1] | 154000-6400 | GOVERNOR HOUSING |

| 3. | [1] | 029632-5070 | O-RING |

| 4. | [1] | 154007-2900 | CAPSULE |

| 6. | [1] | 154007-0200 | ADAPTOR |

| 7. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 9. | [1] | 154350-1900 | PLATE |

| 10. | [6] | 029010-6810 | BLEEDER SCREW |

| 12. | [1] | 154013-4000 | FLAT-HEAD SCREW |

| 13. | [1] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154500-3020 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0400 | BUSHING |

| 38. | [1] | 154031-0100 | FLAT-HEAD SCREW |

| 39. | [1] | 013020-6020 | UNION NUT M6P1H5 |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 54. | [1] | 154011-4900 | UNION NUT |

| 56. | [4] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 154050-6120 | STOPPING DEVICE |

| 80. | [1] | 154060-1020 | COVER |

| 82. | [1] | 154062-5001 | BLEEDER SCREW |

| 83. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 84. | [1] | 154062-5101 | BLEEDER SCREW |

| 85. | [2] | 014110-6440 | LOCKING WASHER |

| 85. | [2] | 014110-6440 | LOCKING WASHER |

| 86. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154101-0120 | FLYWEIGHT |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-0120 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-0400 | GOVERNOR SPRING |

| 132. | [1] | 154154-0800 | COILED SPRING |

| 135. | [1] | 154158-1720 | HEADLESS SCREW |

| 136. | [1] | 154011-2700 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154178-9220 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-6920 | SWIVELLING LEVER |

| 151. | [1] | 154204-3000 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-3100 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154210-0820 | FORK LEVER |

| 174. | [1] | 154230-3920 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-4100 | TENSIONING LEVER |

| 182. | [1] | 154237-0100 | BEARING PIN |

| 190. | [1] | 154342-9720 | CONTROL LEVER |

| 191. | [1] | 154364-7800 | CONTROL LEVER |

| 192. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 201. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5120 | CONTROL LEVER |

| 208. | [1] | 154327-7300 | COILED SPRING |

| 211/1. | [0] | 029311-0520 | SHIM D20.8&10.3T0.2 |

| 211/1. | [0] | 029311-0530 | SHIM D20.8&10.3T0.25 |

| 211/1. | [0] | 029311-0540 | SHIM D20.8&10.3T0.3 |

| 211/1. | [0] | 029311-0550 | SHIM D20.8&10.3T0.35 |

| 211/1. | [0] | 029311-0560 | SHIM D20.8&10.3T0.4 |

| 211/1. | [0] | 029311-0570 | SHIM D20.8&10.3T0.5 |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Add Coolant Additive (Conditioner)

1. Release the cooling system relief valve slowly to relieve pressure and remove filler cap. Inspect condition of cap gasket. Replace cap if necessary.2. It may be necessary to drain enough coolant from the system to allow for the addition of cooling system additive (conditioner).3. Add Caterpillar Cooling System Conditioner. Add 0.24 liter (1/2 U.S. pint) of Caterpillar Cooling System Additive (Conditioner) for each 38 liter (10 U.S. gallon) of cooling system capacity. This will maintain the required concentration of conditioner. On new, rebuilt or remanufactured engines only, or when draining and changing the coolant, add liquid additive concentration of coolant additive of 1 liter (1 U.S. quart) for every 15 liter (4 U.S. gallon) of cooling system capacity for systems using water as coolant only.Caterpillar Antifreeze contains the necessary coolant additive precharge. Only add the coolant additive precharge if you have decided not to use Caterpillar Antifreeze.Refer to the Refill Capacities chart in this publication for the cooling system capacity for your engine.

Do not use any Methoxypropanol-based antifreeze or coolants such as Dowtherm 209 Full-Fill coolant in the cooling system. Methoxypropanol will cause some seals and gaskets to deteriorate and fail.

4. Maintain coolant level to within 13 mm (1/2 in) below the bottom of the filler tube or to the proper level (upper half) on the sight glass, if equipped. Add premixed coolant if necessary to bring the coolant to the proper level.Refer to the topic Cooling System Specifications in the Specifications section in this manual for additional information about coolant mixture and supplemental coolant additive.5. Start the engine and check for leaks or damaged piping. Allow the coolant level to stabilize. Inspect the cooling system pipes and lines for leaks and/or damaged connections. Make repairs if necessary. Install the filler cap.Coolant Analysis

Obtain Coolant Sample

There are

1. Release the cooling system relief valve slowly to relieve pressure and remove filler cap. Inspect condition of cap gasket. Replace cap if necessary.2. It may be necessary to drain enough coolant from the system to allow for the addition of cooling system additive (conditioner).3. Add Caterpillar Cooling System Conditioner. Add 0.24 liter (1/2 U.S. pint) of Caterpillar Cooling System Additive (Conditioner) for each 38 liter (10 U.S. gallon) of cooling system capacity. This will maintain the required concentration of conditioner. On new, rebuilt or remanufactured engines only, or when draining and changing the coolant, add liquid additive concentration of coolant additive of 1 liter (1 U.S. quart) for every 15 liter (4 U.S. gallon) of cooling system capacity for systems using water as coolant only.Caterpillar Antifreeze contains the necessary coolant additive precharge. Only add the coolant additive precharge if you have decided not to use Caterpillar Antifreeze.Refer to the Refill Capacities chart in this publication for the cooling system capacity for your engine.

Do not use any Methoxypropanol-based antifreeze or coolants such as Dowtherm 209 Full-Fill coolant in the cooling system. Methoxypropanol will cause some seals and gaskets to deteriorate and fail.

4. Maintain coolant level to within 13 mm (1/2 in) below the bottom of the filler tube or to the proper level (upper half) on the sight glass, if equipped. Add premixed coolant if necessary to bring the coolant to the proper level.Refer to the topic Cooling System Specifications in the Specifications section in this manual for additional information about coolant mixture and supplemental coolant additive.5. Start the engine and check for leaks or damaged piping. Allow the coolant level to stabilize. Inspect the cooling system pipes and lines for leaks and/or damaged connections. Make repairs if necessary. Install the filler cap.Coolant Analysis

Obtain Coolant Sample

There are