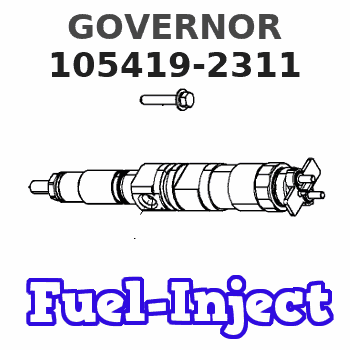

Information governor

BOSCH

9 420 610 738

9420610738

ZEXEL

105419-2311

1054192311

Rating:

Scheme ###:

| 1. | [1] | 154000-6400 | GOVERNOR HOUSING |

| 3. | [1] | 029632-5070 | O-RING |

| 4. | [1] | 154007-2900 | CAPSULE |

| 6. | [1] | 154007-0200 | ADAPTOR |

| 7. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 9. | [1] | 154350-1900 | PLATE |

| 10. | [6] | 029010-6810 | BLEEDER SCREW |

| 12. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 14. | [1] | 154013-2320 | BLEEDER SCREW |

| 15. | [1] | 014110-8440 | LOCKING WASHER |

| 35. | [1] | 154500-1020 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0400 | BUSHING |

| 38. | [1] | 154031-3000 | FLAT-HEAD SCREW |

| 39. | [1] | 139206-0600 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-0200 | FLAT-HEAD SCREW |

| 56. | [4] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 153020-5220 | STOPPING DEVICE |

| 66. | [1] | 026518-2240 | GASKET D21.9&18.2T1 |

| 80. | [1] | 154063-5100 | COVER |

| 82. | [1] | 029020-6260 | BLEEDER SCREW |

| 83. | [1] | 029020-6260 | BLEEDER SCREW |

| 84. | [1] | 020006-2040 | BLEEDER SCREW M6P1L20 4T |

| 86. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154101-0020 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-0120 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-2900 | GOVERNOR SPRING |

| 132. | [1] | 154154-0701 | COILED SPRING |

| 135. | [1] | 154158-0920 | HEADLESS SCREW |

| 136. | [1] | 154011-1700 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154185-6120 | HEADLESS SCREW |

| 141. | [1] | 029201-6080 | UNION NUT |

| 150. | [1] | 154200-6920 | SWIVELLING LEVER |

| 151. | [1] | 154204-3000 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-3100 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154216-3820 | FORK LEVER |

| 174. | [1] | 154230-3920 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-4100 | TENSIONING LEVER |

| 182. | [1] | 154237-0100 | BEARING PIN |

| 190. | [1] | 154395-6420 | CONTROL LEVER |

| 191. | [1] | 154382-9320 | CONTROL LEVER |

| 192. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 195. | [1] | 154314-2600 | COILED SPRING |

| 201. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5020 | CONTROL LEVER |

| 208. | [1] | 154327-7400 | COILED SPRING |

| 211/1. | [0] | 029311-0520 | SHIM D20.8&10.3T0.2 |

| 211/1. | [0] | 029311-0530 | SHIM D20.8&10.3T0.25 |

| 211/1. | [0] | 029311-0540 | SHIM D20.8&10.3T0.3 |

| 211/1. | [0] | 029311-0550 | SHIM D20.8&10.3T0.35 |

| 211/1. | [0] | 029311-0560 | SHIM D20.8&10.3T0.4 |

| 211/1. | [0] | 029311-0570 | SHIM D20.8&10.3T0.5 |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 331. | [1] | 154188-3320 | HEADLESS SCREW |

| 332. | [1] | 029201-6010 | UNION NUT |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 400. | [1] | 154358-7200 | BRACKET |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105419-2311

9 420 610 738

GOVERNOR

* K

* K

Information:

Adjust -to conform and correspond to specifications. Check -to observe for satisfactory conditions, accuracy, safety or performance. Exchange -to trade a worn or failing component for a remanufactured or rebuilt component. Inspect -to examine closely, in critical appraisal, while testing or evaluating components or systems. Lubricate -to apply a lubricant (oil, grease, etc.) as specified for reducing friction, heat and wear between solid surfaces. Protective Devices -indicators such as gauges, lights, emergency shutoffs, etc., that alert an operator that a potential problem may exist. Failure to respond to these indicators in a timely manner could result in engine failure. Rebuild -to repair a worn or failing component with new parts, components and/or remanufactured components. Replace -to install something new, remanufactured or rebuilt in place of an existing worn or failing component. Service Hours (Electrical) -records the time (clock hours) the engine is actually running but does not reflect variations in speed, load, etc.Interval Categories

Engine components can generally be grouped into speed sensitive and load sensitive categories. Therefore, the maintenance interval for each item listed in the Maintenance Management Schedule is primarily based on the item and its relationship to either engine speed or load. Speed sensitive items such as water pumps, air compressors, etc., are not primarily affected by the load on your engine during operation. The load on an engine will not significantly accelerate the repair or replacement cycle for speed sensitive items.Therefore, the maintenance intervals established for speed sensitive items are based on miles (kilometers) or service hours, whichever occurs first. Load sensitive items such as piston rings, cylinder liners, etc., are affected by the load on your engine during operation. Generally speaking, the lower the load, the longer the engine life and conversely, the higher the load, the shorter the engine life. A heavy load on an engine will accelerate the repair or replacement cycle for load sensitive items.Load sensitive items are normally internal engine components and the amount of fuel consumed is directly related to the load on your engine.Therefore, the maintenance interval for load sensitive items include fuel consumption, since the amount of fuel consumed is directly related to the load on your engine.Since the amount of fuel consumed is a better indicator of performing an overhaul than miles (kilometers) or service hours, Caterpillar recommends performing an overhaul on these items at the specified maintenance interval based on the quantity of fuel consumed.Interval to Overhaul

The specified overhaul interval for the 3176 Truck engine is "Every 80,000 Gallons (303 200 L) of Fuel or 500,000 Miles (805 000 km) or 10,000 Service Hours." The Maintenance Management Schedule follows. Ensure that the schedule is adhered to. PM Level means Preventive Maintenance Level.

Engine components can generally be grouped into speed sensitive and load sensitive categories. Therefore, the maintenance interval for each item listed in the Maintenance Management Schedule is primarily based on the item and its relationship to either engine speed or load. Speed sensitive items such as water pumps, air compressors, etc., are not primarily affected by the load on your engine during operation. The load on an engine will not significantly accelerate the repair or replacement cycle for speed sensitive items.Therefore, the maintenance intervals established for speed sensitive items are based on miles (kilometers) or service hours, whichever occurs first. Load sensitive items such as piston rings, cylinder liners, etc., are affected by the load on your engine during operation. Generally speaking, the lower the load, the longer the engine life and conversely, the higher the load, the shorter the engine life. A heavy load on an engine will accelerate the repair or replacement cycle for load sensitive items.Load sensitive items are normally internal engine components and the amount of fuel consumed is directly related to the load on your engine.Therefore, the maintenance interval for load sensitive items include fuel consumption, since the amount of fuel consumed is directly related to the load on your engine.Since the amount of fuel consumed is a better indicator of performing an overhaul than miles (kilometers) or service hours, Caterpillar recommends performing an overhaul on these items at the specified maintenance interval based on the quantity of fuel consumed.Interval to Overhaul

The specified overhaul interval for the 3176 Truck engine is "Every 80,000 Gallons (303 200 L) of Fuel or 500,000 Miles (805 000 km) or 10,000 Service Hours." The Maintenance Management Schedule follows. Ensure that the schedule is adhered to. PM Level means Preventive Maintenance Level.

Have questions with 105419-2311?

Group cross 105419-2311 ZEXEL

105419-2311

9 420 610 738

GOVERNOR