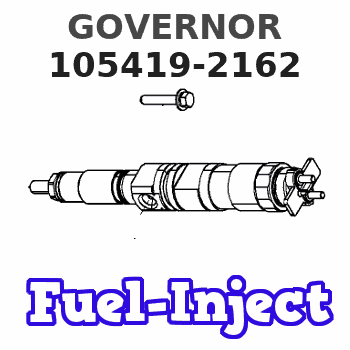

Information governor

BOSCH

F 019 Z3E 901

f019z3e901

ZEXEL

105419-2162

1054192162

Rating:

Scheme ###:

| 1. | [1] | 154000-6400 | GOVERNOR HOUSING |

| 3. | [1] | 029632-5070 | O-RING |

| 4. | [1] | 154007-2900 | CAPSULE |

| 6. | [1] | 154007-0200 | ADAPTOR |

| 7. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 9. | [1] | 154350-1900 | PLATE |

| 10. | [6] | 029010-6810 | BLEEDER SCREW |

| 12. | [1] | 154010-7300 | BLEEDER SCREW M8P1.25L60 |

| 13. | [1] | 154011-0100 | HEXAGON NUT |

| 14. | [1] | 154013-2320 | BLEEDER SCREW |

| 15. | [1] | 014110-8440 | LOCKING WASHER |

| 35. | [1] | 154500-1020 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0400 | BUSHING |

| 38. | [1] | 154031-3000 | FLAT-HEAD SCREW |

| 39. | [1] | 139206-0600 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-0200 | FLAT-HEAD SCREW |

| 54. | [1] | 154011-2300 | UNION NUT |

| 56. | [4] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 155404-5120 | STOPPING DEVICE |

| 66. | [1] | 026518-2240 | GASKET D21.9&18.2T1 |

| 80. | [1] | 154063-5100 | COVER |

| 82. | [1] | 029020-6260 | BLEEDER SCREW |

| 83. | [1] | 029020-6260 | BLEEDER SCREW |

| 84. | [1] | 020006-2040 | BLEEDER SCREW M6P1L20 4T |

| 86. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154101-0020 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-0120 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-2900 | GOVERNOR SPRING |

| 132. | [1] | 154154-0701 | COILED SPRING |

| 135. | [1] | 154158-2320 | HEADLESS SCREW |

| 136. | [1] | 154011-1700 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154185-4120 | HEADLESS SCREW |

| 141. | [1] | 029201-6080 | UNION NUT |

| 150. | [1] | 154200-6920 | SWIVELLING LEVER |

| 151. | [1] | 154204-4300 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-4400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154216-3820 | FORK LEVER |

| 174. | [1] | 154230-3920 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-4100 | TENSIONING LEVER |

| 182. | [1] | 154237-0100 | BEARING PIN |

| 190. | [1] | 154395-6920 | CONTROL LEVER |

| 191. | [1] | 154382-6020 | CONTROL LEVER |

| 192. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 195. | [1] | 154314-2600 | COILED SPRING |

| 201. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5020 | CONTROL LEVER |

| 208. | [1] | 154327-7600 | COILED SPRING |

| 211/1. | [0] | 139410-1300 | SHIM D20.8&10.2T0.3 |

| 211/1. | [0] | 139410-1700 | SHIM D20.8&10.2T0.2 |

| 211/1. | [0] | 139410-1800 | SHIM D20.8&10.2T0.4 |

| 211/1. | [0] | 139410-2800 | SHIM D20.8&10.2T0.6 |

| 211/1. | [0] | 139410-3700 | SHIM D20.8&10.2T0.9 |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 331. | [1] | 154172-7420 | HEADLESS SCREW |

| 332. | [1] | 029201-6010 | UNION NUT |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-2500 | CAP NUT |

| 400. | [1] | 154358-7200 | BRACKET |

| 835S. | [1] | 154062-2000 | CAP D14L30.5 |

| 836S. | [1] | 154062-1700 | CAP D20L32 |

Include in #1:

101402-9412

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Filters and Pump Housing

1. Open the bleed valve on the pump housing. 2. Unscrew the hand priming pump plunger until it can be pulled out by hand. 3. Move the plunger in and out until fuel flows, free of air bubbles, from the bleed valve. 4. Close the bleed valve. 5. Push the plunger in and tighten by hand.6. Start the engine and check for leaks.Injection Pumps and Lines

The injection pumps and high pressure lines must be primed if the engine will not start, or runs rough, after priming the filters and pump housing.Each injection pump has a reverse flow check valve. These cannot be opened with hand priming pump pressure. Use the following procedure to prime the injection pumps and lines.

The fuel injection nozzles can be permanently damaged by twisting if only one wrench is used to loosen or tighten the fuel line nuts. Use one wrench to hold the nozzle and another to loosen the nut.

1. Loosen each of the fuel line nuts at the cylinder head end.2. Crank the engine with the starting motor until fuel flows, free of air bubbles, from each of the injection lines. Stop cranking the engine.3. Tighten each of the fuel line nuts to a torque of 41 + 7 N m (30 + 5 lb. ft.). Use a second wrench on the nozzle to prevent damage to it.4. Start the engine and check for leaks.

1. Open the bleed valve on the pump housing. 2. Unscrew the hand priming pump plunger until it can be pulled out by hand. 3. Move the plunger in and out until fuel flows, free of air bubbles, from the bleed valve. 4. Close the bleed valve. 5. Push the plunger in and tighten by hand.6. Start the engine and check for leaks.Injection Pumps and Lines

The injection pumps and high pressure lines must be primed if the engine will not start, or runs rough, after priming the filters and pump housing.Each injection pump has a reverse flow check valve. These cannot be opened with hand priming pump pressure. Use the following procedure to prime the injection pumps and lines.

The fuel injection nozzles can be permanently damaged by twisting if only one wrench is used to loosen or tighten the fuel line nuts. Use one wrench to hold the nozzle and another to loosen the nut.

1. Loosen each of the fuel line nuts at the cylinder head end.2. Crank the engine with the starting motor until fuel flows, free of air bubbles, from each of the injection lines. Stop cranking the engine.3. Tighten each of the fuel line nuts to a torque of 41 + 7 N m (30 + 5 lb. ft.). Use a second wrench on the nozzle to prevent damage to it.4. Start the engine and check for leaks.