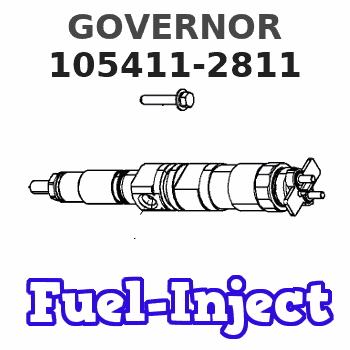

Information governor

BOSCH

F 019 Z9E 536

f019z9e536

ZEXEL

105411-2811

1054112811

Rating:

Scheme ###:

| 1. | [1] | 154004-5620 | GOVERNOR HOUSING |

| 2. | [1] | 154007-2900 | CAPSULE |

| 3. | [1] | 154390-2000 | GASKET |

| 4. | [1] | 154064-4500 | COVER |

| 5. | [4] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 6. | [1] | 154007-0200 | ADAPTOR |

| 7. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 8. | [1] | 029632-5070 | O-RING |

| 9. | [1] | 154350-1800 | PLATE |

| 10. | [5] | 029010-6810 | BLEEDER SCREW |

| 11. | [1] | 020106-1640 | BLEEDER SCREW M6P1.0L14 |

| 12. | [1] | 154010-1100 | FLAT-HEAD SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 16. | [1] | 155004-3200 | LEVER SHAFT |

| 18. | [1] | 155003-2520 | CONTROL LEVER |

| 19. | [1] | 155006-0700 | BLEEDER SCREW |

| 20. | [1] | 139308-0900 | PLAIN WASHER D16&8T1 |

| 20. | [1] | 139308-0900 | PLAIN WASHER D16&8T1 |

| 20B. | [1] | 139308-1000 | PLAIN WASHER D16&8T1.5 |

| 20B. | [1] | 139308-1000 | PLAIN WASHER D16&8T1.5 |

| 20C. | [1] | 139408-1500 | SHIM |

| 23. | [1] | 025520-1210 | SPLIT PIN |

| 24. | [1] | 154206-6300 | BUSHING |

| 25. | [1] | 154327-4200 | COILED SPRING |

| 26. | [1] | 154383-3100 | CONTROL LEVER |

| 27. | [1] | 014110-8440 | LOCKING WASHER |

| 28. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 29. | [1] | 139408-1500 | SHIM |

| 29B. | [0] | 139408-1400 | SHIM |

| 29C. | [0] | 139408-1500 | SHIM |

| 30. | [2] | 029620-8050 | PACKING RING |

| 30. | [2] | 029620-8050 | PACKING RING |

| 35. | [1] | 154022-5420 | GOVERNOR COVER |

| 38. | [1] | 154031-1300 | FLAT-HEAD SCREW |

| 39. | [1] | 139206-0600 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [2] | 139006-7100 | BLEEDER SCREW |

| 51B. | [4] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 65. | [1] | 154050-6120 | STOPPING DEVICE |

| 80. | [1] | 154063-5420 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154101-0120 | FLYWEIGHT |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154151-1500 | GOVERNOR SPRING |

| 132. | [1] | 154154-0701 | COILED SPRING |

| 135. | [1] | 154158-0820 | HEADLESS SCREW |

| 136. | [1] | 029201-2290 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154177-4420 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-7920 | SWIVELLING LEVER |

| 151. | [1] | 154204-4300 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-4400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154217-0420 | FORK LEVER |

| 171. | [1] | 016010-0540 | LOCKING WASHER |

| 172. | [3] | 029310-5170 | SHIM D8&5.3T0.5 |

| 172. | [3] | 029310-5170 | SHIM D8&5.3T0.5 |

| 173. | [2] | 025520-1210 | SPLIT PIN |

| 173. | [2] | 025520-1210 | SPLIT PIN |

| 174. | [1] | 154235-4820 | STRAP |

| 175. | [1] | 154232-3000 | CONNECTOR |

| 176. | [1] | 154222-5800 | BEARING PIN |

| 177. | [1] | 155402-3800 | SAFETY PIN |

| 181. | [1] | 154239-5920 | TENSIONING LEVER |

| 182. | [1] | 154237-0100 | BEARING PIN |

| 190. | [1] | 154340-2020 | CONTROL LEVER |

| 236. | [1] | 154390-1300 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 255. | [1] | 154400-7820 | DIAPHRAGM |

| 256. | [1] | 154400-4800 | STOP PIN |

| 257. | [2] | 029330-8050 | GASKET |

| 257. | [2] | 029330-8050 | GASKET |

| 258. | [1] | 139308-0700 | LOCKING WASHER |

| 259. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 260. | [1] | 154401-0120 | CONTROL LEVER |

| 261. | [1] | 154401-1120 | STRAP |

| 262. | [1] | 026510-1440 | GASKET D13.9&10.2T1 |

| 263. | [1] | 154401-2100 | BLEEDER SCREW |

| 264. | [1] | 016010-0540 | LOCKING WASHER |

| 265. | [1] | 154222-6200 | BEARING PIN |

| 266. | [1] | 029300-4010 | PLAIN WASHER |

| 267. | [1] | 154425-3900 | COILED SPRING |

| 268. | [1] | 154404-5000 | COVER |

| 269. | [2] | 020106-2540 | BLEEDER SCREW M6P1L25 |

| 270. | [1] | 154034-2700 | FLAT-HEAD SCREW |

| 271. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 273. | [1] | 029731-0180 | EYE BOLT |

| 274. | [2] | 026510-1340 | GASKET D13.4&10.2T1 |

| 275. | [0] | 029312-0180 | SHIM D25.5&20T0.5 |

| 275B. | [0] | 029312-0210 | SHIM D25.5&20T0.2 |

| 276. | [1] | 154035-1600 | CAP NUT |

| 277. | [1] | 014110-6440 | LOCKING WASHER |

| 278. | [2] | 154413-2600 | GASKET |

| 278. | [2] | 154413-2600 | GASKET |

| 279. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 283. | [1] | 016010-0440 | LOCKING WASHER |

| 285. | [1] | 029010-6310 | BLEEDER SCREW |

| 300. | [1] | 154358-9420 | BRACKET |

| 301. | [1] | 020118-1640 | BLEEDER SCREW |

| 303. | [1] | 154011-1100 | UNION NUT |

| 304. | [1] | 029300-8320 | SHIM |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 353. | [2] | 029310-9080 | SHIM D16&9T1.7 |

Include in #1:

101405-9491

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Recommended Procedure

1. Tachometer Error ... To check, connect a tachometer of known accuracy to the engine. Run the engine and make a comparison of the readings of the vehicle and test tachometers. If vehicle tachometer is bad, make repairs as necessary or install a new tachometer.2. Engine Operated at High Altitude ... Less oxygen at higher altitudes causes the engine horsepower to go down. There is no effect on the horsepower of the engine for the first 7500 ft. (2280 m) above sea level of operation.3. Brakes Do Not Completely Release ... Check the brakes by feeling all the brake drums. If the brakes of a wheel do not completely release, the brake drum for that wheel will be hotter than the brake drums for the other wheels. With the truck lifted with a jack, the wheels must have free rotation when turned by hand.4. Vehicle Operated in Too High a Gear ... If the operator does not shift the truck correctly, or operates the truck in a "lug" condition (using the truck in too high a gear for engine rpm to go up as acclerator pedal is pushed farther down, or using the truck in a gear where engine rpm goes down with accelerator pedal at maximum travel), poor vehicle performance is the result.5. Extra Engine Driven Equipment ... Air compressors, hydraulic pumps, alternator, and other engine driven equipment that has damage, or that was not installed correctly, or that is not in correct adjustment, can take more horsepower to drive than expected. If necessary, disconnect the equipment and test the engine.6. Speedometer Error ... A bad speedometer does not give the correct speed or the correct indication of fuel consumption. An indication of low speed can cause the operator to feel that he has a power problem.7. Speeds Too High ... The need for more horsepower is easy to see as the speed of the vehicle is increased. This is especially true if the front of the vehicle has a large surface area. Application personnel can give you the horsepower necessary for different vehicle designs at different speeds.8. Overload on Vehicle ... Application personnel can give you the horsepower needs for different vehicles.9. High Moving Resistance ... Soft ground conditions cause a need for more horsepower. To see if the problem is the engine, test the vehicle on a surface known to be good, or test on a chassis dynamometer.10. High Wind Resistance ... The horsepower needs for a truck can be divided into two parts. Part of the horsepower is used to move the vehicle and part is used to get through the resistance of the wind. The horsepower necessary to get through the resistance of the wind will increase as the vehicle is used at higher speeds. Vehicles with large front area have a higher wind resistance and take more horsepower than those with a small front area. Some types of trucks, for example those used for the transportation of automobiles and/or boats

1. Tachometer Error ... To check, connect a tachometer of known accuracy to the engine. Run the engine and make a comparison of the readings of the vehicle and test tachometers. If vehicle tachometer is bad, make repairs as necessary or install a new tachometer.2. Engine Operated at High Altitude ... Less oxygen at higher altitudes causes the engine horsepower to go down. There is no effect on the horsepower of the engine for the first 7500 ft. (2280 m) above sea level of operation.3. Brakes Do Not Completely Release ... Check the brakes by feeling all the brake drums. If the brakes of a wheel do not completely release, the brake drum for that wheel will be hotter than the brake drums for the other wheels. With the truck lifted with a jack, the wheels must have free rotation when turned by hand.4. Vehicle Operated in Too High a Gear ... If the operator does not shift the truck correctly, or operates the truck in a "lug" condition (using the truck in too high a gear for engine rpm to go up as acclerator pedal is pushed farther down, or using the truck in a gear where engine rpm goes down with accelerator pedal at maximum travel), poor vehicle performance is the result.5. Extra Engine Driven Equipment ... Air compressors, hydraulic pumps, alternator, and other engine driven equipment that has damage, or that was not installed correctly, or that is not in correct adjustment, can take more horsepower to drive than expected. If necessary, disconnect the equipment and test the engine.6. Speedometer Error ... A bad speedometer does not give the correct speed or the correct indication of fuel consumption. An indication of low speed can cause the operator to feel that he has a power problem.7. Speeds Too High ... The need for more horsepower is easy to see as the speed of the vehicle is increased. This is especially true if the front of the vehicle has a large surface area. Application personnel can give you the horsepower necessary for different vehicle designs at different speeds.8. Overload on Vehicle ... Application personnel can give you the horsepower needs for different vehicles.9. High Moving Resistance ... Soft ground conditions cause a need for more horsepower. To see if the problem is the engine, test the vehicle on a surface known to be good, or test on a chassis dynamometer.10. High Wind Resistance ... The horsepower needs for a truck can be divided into two parts. Part of the horsepower is used to move the vehicle and part is used to get through the resistance of the wind. The horsepower necessary to get through the resistance of the wind will increase as the vehicle is used at higher speeds. Vehicles with large front area have a higher wind resistance and take more horsepower than those with a small front area. Some types of trucks, for example those used for the transportation of automobiles and/or boats