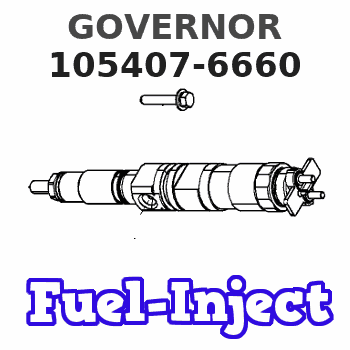

Information governor

BOSCH

9 420 610 625

9420610625

ZEXEL

105407-6660

1054076660

HINO

223205160A

223205160a

Rating:

Scheme ###:

| 1. | [1] | 154004-2822 | GOVERNOR HOUSING |

| 2. | [1] | 154007-2900 | CAPSULE |

| 3. | [1] | 154358-2500 | SEAL RING |

| 4. | [1] | 154064-4500 | COVER |

| 5. | [4] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 8. | [1] | 029632-5070 | O-RING |

| 9. | [1] | 154350-6000 | PLATE |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 12. | [1] | 154010-1100 | FLAT-HEAD SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 16. | [1] | 155004-3600 | LEVER SHAFT |

| 18. | [1] | 155003-2101 | CONTROL LEVER |

| 19. | [1] | 155006-0700 | BLEEDER SCREW |

| 20. | [1] | 139308-0900 | PLAIN WASHER D16&8T1 |

| 20. | [1] | 139308-0900 | PLAIN WASHER D16&8T1 |

| 20B. | [1] | 139308-1000 | PLAIN WASHER D16&8T1.5 |

| 20B. | [1] | 139308-1000 | PLAIN WASHER D16&8T1.5 |

| 23. | [1] | 025520-1210 | SPLIT PIN |

| 24. | [1] | 154206-2000 | BUSHING |

| 25. | [1] | 154327-3600 | COILED SPRING |

| 26. | [1] | 154382-2300 | CONTROL LEVER |

| 27. | [1] | 014110-8440 | LOCKING WASHER |

| 28. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 29. | [1] | 139408-1500 | SHIM |

| 29B. | [0] | 139408-1400 | SHIM |

| 29C. | [0] | 139408-1500 | SHIM |

| 30. | [2] | 029620-8050 | PACKING RING |

| 30. | [2] | 029620-8050 | PACKING RING |

| 35. | [1] | 154022-6020 | GOVERNOR COVER |

| 38. | [1] | 154031-4800 | FLAT-HEAD SCREW |

| 39. | [1] | 139208-0400 | UNION NUT |

| 47. | [1] | 154036-0300 | CAPSULE |

| 51. | [6] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 65. | [1] | 153021-2220 | STOPPING DEVICE |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154063-7300 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154101-0020 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-2900 | GOVERNOR SPRING |

| 132. | [1] | 154154-0500 | COILED SPRING |

| 135. | [1] | 154158-0820 | HEADLESS SCREW |

| 136. | [1] | 029201-2290 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154185-1320 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-7020 | SWIVELLING LEVER |

| 151. | [1] | 154204-4300 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-4400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154217-2920 | FORK LEVER |

| 171. | [1] | 016010-0540 | LOCKING WASHER |

| 172. | [4] | 029310-5170 | SHIM D8&5.3T0.5 |

| 172. | [4] | 029310-5170 | SHIM D8&5.3T0.5 |

| 173. | [3] | 025520-1210 | SPLIT PIN |

| 173. | [3] | 025520-1210 | SPLIT PIN |

| 174. | [1] | 154235-5020 | STRAP |

| 175. | [1] | 154232-2420 | CONNECTOR |

| 176. | [1] | 159231-4900 | BEARING PIN |

| 177. | [1] | 155402-3800 | SAFETY PIN |

| 181. | [1] | 154236-4100 | TENSIONING LEVER |

| 182. | [1] | 154237-1100 | BEARING PIN |

| 190. | [1] | 154341-8120 | CONTROL LEVER |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 253. | [1] | 029320-5020 | LOCKING WASHER |

| 254. | [1] | 010535-1040 | FLAT-HEAD SCREW M5P0.8L10 |

| 255. | [1] | 154400-7420 | DIAPHRAGM |

| 256. | [1] | 154400-4800 | STOP PIN |

| 257. | [2] | 029330-8050 | GASKET |

| 257. | [2] | 029330-8050 | GASKET |

| 258. | [1] | 139308-0700 | LOCKING WASHER |

| 259. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 260. | [1] | 154401-3620 | CONTROL LEVER |

| 261. | [1] | 154401-1320 | STRAP |

| 262. | [1] | 026510-1440 | GASKET D13.9&10.2T1 |

| 263. | [1] | 154401-2100 | BLEEDER SCREW |

| 264. | [1] | 016010-0540 | LOCKING WASHER |

| 265. | [1] | 154222-6200 | BEARING PIN |

| 266. | [1] | 029300-4010 | PLAIN WASHER |

| 267. | [1] | 154402-4100 | COILED SPRING |

| 268. | [1] | 154404-5000 | COVER |

| 269. | [2] | 020106-2540 | BLEEDER SCREW M6P1L25 |

| 270. | [1] | 154034-1900 | FLAT-HEAD SCREW |

| 271. | [1] | 023040-6040 | UNION NUT |

| 273. | [1] | 029731-0180 | EYE BOLT |

| 274. | [2] | 026510-1340 | GASKET D13.4&10.2T1 |

| 275. | [0] | 029312-0180 | SHIM D25.5&20T0.5 |

| 275B. | [0] | 029312-0210 | SHIM D25.5&20T0.2 |

| 276. | [1] | 154035-0320 | CAP NUT |

| 277. | [1] | 014110-6440 | LOCKING WASHER |

| 278. | [2] | 154413-2600 | GASKET |

| 278. | [2] | 154413-2600 | GASKET |

| 283. | [1] | 016010-0440 | LOCKING WASHER |

| 285. | [1] | 029010-6310 | BLEEDER SCREW |

| 300. | [1] | 154359-1320 | BRACKET |

| 301. | [1] | 020118-1640 | BLEEDER SCREW |

| 303. | [1] | 154011-1100 | UNION NUT |

| 304. | [1] | 029300-8320 | SHIM |

| 335. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 336. | [1] | 154035-2000 | CAP NUT |

| 353. | [1] | 029310-9080 | SHIM D16&9T1.7 |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105407-6660

223205160A HINO

GOVERNOR

K 14JB MECHANICAL GOVERNOR GOV RSV GOV

K 14JB MECHANICAL GOVERNOR GOV RSV GOV

Information:

Cautions Regarding Battery* Handle Battery Carefully * Never use flames or allow sparks near the battery. The battery releases flammable hydrogen gas and oxygen gas. These gases can be ignited by flames and cause an explosion.* Do not use the battery when the fluid surface is lower than the minimum level. Using a battery with a low electrolyte level can result in an explosion.* Do not short the battery terminals with a tool or other metal object.* When disconnecting battery cables, always remove the cable from the negative (-) terminal first. When reconnecting cables, attach the cable to the positive (+) terminal first.* Charge the battery in a well-ventilated area, with all filling hole plugs removed.* Make sure the cable clamps are securely installed on the battery terminals. A loose cable clamp can cause sparks that may result in explosion.* Before servicing electrical components or conducting electrical welding, set the battery switch to the [Open/OFF] position or disconnect the cable from the negative (-) battery terminal to cut off the electrical current.* Electrolyte (battery fluid) contains dilute sulfuric acid. Careless handling of the battery can lead to the loss of sight and/or burns. Also, do not swallow electrolyte.* Wear protective goggles and rubber gloves when maintaining and inspecting the battery (when adding water, charging, etc.).* If electrolyte is spilled onto the skin or clothes, immediately wash with lots of clean fresh water and thoroughly clean with soap.* If electrolyte gets into eyes, immediately flush with lots of clean fresh water and seek immediate medical attention.* Should you accidentally swallow electrolyte, gargle with plenty of water, then drink lots of water, and seek immediate medical attention.

Response To Abnormalities* If Engine Overheats, Conduct Heating Operation Before Stopping The Engine If the engine overheats, do not stop the engine immediately. Abruptly stopping an overheated engine may cause the coolant temperature to rise, resulting in seizing of the engine. If the engine overheats, operate the engine at low idling speed (cooling temperature), and stop the engine after the coolant temperature lowers sufficiently.Do not add coolant immediately after stopping the engine. Adding coolant to a hot engine may cause damage to the cylinder heads due to sudden change in temperature. Add coolant after the engine cools to room temperature.* If Engine Stops Due To Abnormality, Exercise Caution When Restarting If the engine stops due to an abnormality, do not restart the engine immediately. If the engine stops with an alarm, check and correct the cause of the problem before restarting. Operating the engine without correcting the problem may result in serious engine problems.* If Oil Pressure Drops, Stop Engine Immediately If the engine oil pressure decreases, stop the engine immediately, and inspect the lubrication system. Operating the engine with low oil pressure may cause seizing of the bearings and other parts.* If Fan Belt Breaks, Stop Engine Immediately If the fan belt breaks, stop the engine immediately. Continued operation of the engine without the fan belt causes coolant to change to steam and

Response To Abnormalities* If Engine Overheats, Conduct Heating Operation Before Stopping The Engine If the engine overheats, do not stop the engine immediately. Abruptly stopping an overheated engine may cause the coolant temperature to rise, resulting in seizing of the engine. If the engine overheats, operate the engine at low idling speed (cooling temperature), and stop the engine after the coolant temperature lowers sufficiently.Do not add coolant immediately after stopping the engine. Adding coolant to a hot engine may cause damage to the cylinder heads due to sudden change in temperature. Add coolant after the engine cools to room temperature.* If Engine Stops Due To Abnormality, Exercise Caution When Restarting If the engine stops due to an abnormality, do not restart the engine immediately. If the engine stops with an alarm, check and correct the cause of the problem before restarting. Operating the engine without correcting the problem may result in serious engine problems.* If Oil Pressure Drops, Stop Engine Immediately If the engine oil pressure decreases, stop the engine immediately, and inspect the lubrication system. Operating the engine with low oil pressure may cause seizing of the bearings and other parts.* If Fan Belt Breaks, Stop Engine Immediately If the fan belt breaks, stop the engine immediately. Continued operation of the engine without the fan belt causes coolant to change to steam and