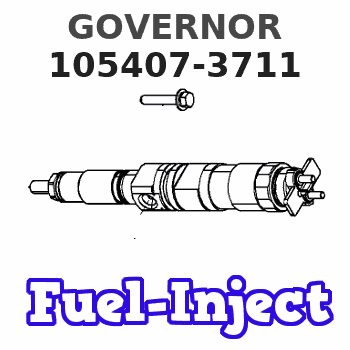

Information governor

BOSCH

9 420 610 187

9420610187

ZEXEL

105407-3711

1054073711

Rating:

Scheme ###:

| 1. | [1] | 154000-5720 | GOVERNOR HOUSING |

| 3. | [1] | 029632-5070 | O-RING |

| 4. | [1] | 154007-2900 | CAPSULE |

| 9. | [1] | 154350-6000 | PLATE |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 12. | [1] | 154010-1100 | FLAT-HEAD SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 14. | [1] | 154012-2220 | BLEEDER SCREW |

| 15. | [1] | 014110-8440 | LOCKING WASHER |

| 35. | [1] | 154500-8120 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0400 | BUSHING |

| 38. | [1] | 154031-4300 | FLAT-HEAD SCREW |

| 39. | [1] | 139208-0400 | UNION NUT |

| 47. | [1] | 154036-0300 | CAPSULE |

| 51. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-0200 | FLAT-HEAD SCREW |

| 56. | [4] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 155404-1700 | CAP |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154063-7300 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154101-0020 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-0400 | GOVERNOR SPRING |

| 132. | [1] | 154154-0500 | COILED SPRING |

| 135. | [1] | 154158-1320 | HEADLESS SCREW |

| 136. | [1] | 154011-1700 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154177-2420 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-7020 | SWIVELLING LEVER |

| 151. | [1] | 154204-3000 | BUSHING |

| 152. | [2] | 139718-0200 | O-RING |

| 152. | [2] | 139718-0200 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0300 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-3100 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154210-2720 | FORK LEVER |

| 174. | [1] | 154230-2920 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-4100 | TENSIONING LEVER |

| 182. | [1] | 154237-1100 | BEARING PIN |

| 190. | [1] | 154343-0920 | CONTROL LEVER |

| 191. | [1] | 154366-4220 | CONTROL LEVER |

| 192. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 195. | [1] | 154314-2500 | COILED SPRING |

| 201. | [1] | 139710-0500 | O-RING |

| 207. | [1] | 154326-5020 | CONTROL LEVER |

| 211. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 211B. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 235. | [1] | 155412-5300 | IMPELLER WHEEL |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 335. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 336. | [1] | 154035-2000 | CAP NUT |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Illustration 7 g06347860

Injector male spade terminals

There are two options to build injector adapter harness for C3.3.If available, use the injector connector removed from C3.3 harness. Cut both 100 mm wires from the connector and attach bullet terminals that fit in the injector adapter harness C3.8 terminal from injector test kit.If no harness is available, build a harness with the following. Two female spade terminals for injector male spade terminal, two 16 gauge 100 mm wires, and two bullet terminals for injector adapter harness C3.8 terminal.

Illustration 8 g06345429

Injector adapter harness C2.4

Illustration 9 g06346223

Injector adapter harness C3.8

Illustration 10 g06346237

Injector male spade terminals

There are two options to build injector adapter harness for C2.4.If available, use the injector connector removed from C2.4 harness. Cut both 100 mm wires from the connector and attach bullet terminals that fit in the injector adapter harness C3.8 terminal from injector test kit.If no harness is available, build a harness with the following. Two female spade terminals for injector male spade terminal, two 16 gauge 100 mm wires, and two bullet terminals for injector adapter harness C3.8 terminal.Injector Test Set-up

Illustration 11 g06346391

Mounted nozzle test group

Find a suitable stable and surface to either mount or place the nozzle test group. Fill fuel container with #1 diesel and install high-pressure hose assembly. Use adaptors, if needed, based on nozzle tester. Tighten the fuel line adapter to (25 ft lbs). Install the fuel line adapter and tighten to (25 ft lbs) to allow connection to the injector.

Illustration 12 g06346423

Injector holder assembly

Take the injector test kit and remove all parts to assemble, as shown above. Take the injector holder and the clear fuel shield with screws from the kit and remove the screws using a 3mm alan wrench. Assemble the parts so the clear fuel shield with screws is on the bottom. While, the mounted injector holder is on top with the screws removed from before.

Illustration 13 g06346719

Fuel collector and injector holder

Place injector holder onto a fuel collector or another container to capture the injection spray.

Illustration 14 g06346839

Injector setup and harness connection

Install the injector that is needing to be tested into the opening at the top of injector holder. Attach the return fuel drain hose and run the drain hose to another fuel collector. Make the harness connection using the correct adapter for the C2.4, C3.3, and C3.8 engines. Connect the injector pulse tool and the injector adapter harness to the injector.

Illustration 15 g06346868

Complete setup of nozzle tester and injector test kit

Once injector test kit and nozzle test group are set up, connect fuel line adaptor on the high-pressure hose assembly to the injector, leave connection loose. Actuate the lever on the nozzle test group until fuel drips from connection allowing air to purge from setup. Tighten fuel line adaptor at injector to (25 ft lbs).Injector Test Procedure

Illustration 16 g06346881

Mounted nozzle test group (close-up)

Inspect the injector for any leaks. Using the lever on the nozzle tester group, build injection fuel pressure to (5000 psi). Turn the locking valve to insure there is no leakage back through the tester.

Let the nozzle test