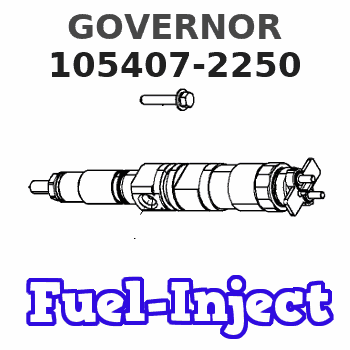

Information governor

BOSCH

F 019 Z4E 310

f019z4e310

ZEXEL

105407-2250

1054072250

HINO

223201900A

223201900a

Rating:

Scheme ###:

| 1. | [1] | 154000-4700 | GOVERNOR HOUSING |

| 3. | [1] | 029632-5070 | O-RING |

| 4. | [1] | 154007-2900 | CAPSULE |

| 9. | [1] | 154350-6000 | PLATE |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 12. | [1] | 154010-1100 | FLAT-HEAD SCREW |

| 13. | [1] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154500-7620 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0400 | BUSHING |

| 38. | [1] | 154031-2400 | FLAT-HEAD SCREW |

| 39. | [1] | 139206-0600 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-5220 | HEADLESS SCREW |

| 54. | [1] | 154011-1900 | UNION NUT |

| 56. | [4] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 153021-5220 | STOPPING DEVICE |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154063-1400 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154101-0020 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-0120 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-2700 | GOVERNOR SPRING |

| 132. | [1] | 154154-0500 | COILED SPRING |

| 135. | [1] | 154158-0820 | HEADLESS SCREW |

| 136. | [1] | 154011-2700 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154185-2120 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-7120 | SWIVELLING LEVER |

| 151. | [1] | 154204-4300 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-4400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154210-2720 | FORK LEVER |

| 174. | [1] | 154230-2920 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-1500 | TENSIONING LEVER |

| 182. | [1] | 154237-0100 | BEARING PIN |

| 190. | [1] | 154343-3120 | CONTROL LEVER |

| 191. | [1] | 154307-5920 | CONTROL LEVER |

| 192. | [1] | 020006-3540 | BLEEDER SCREW |

| 201. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5020 | CONTROL LEVER |

| 208. | [1] | 154327-7600 | COILED SPRING |

| 211/1. | [0] | 029311-0520 | SHIM D20.8&10.3T0.2 |

| 211/1. | [0] | 029311-0530 | SHIM D20.8&10.3T0.25 |

| 211/1. | [0] | 029311-0540 | SHIM D20.8&10.3T0.3 |

| 211/1. | [0] | 029311-0550 | SHIM D20.8&10.3T0.35 |

| 211/1. | [0] | 029311-0560 | SHIM D20.8&10.3T0.4 |

| 211/1. | [0] | 029311-0570 | SHIM D20.8&10.3T0.5 |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Include in #1:

106672-3131

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Locations and Methods for Measuring the Pressures of the Low-Pressure Fuel System

Illustration 1 g03325145

Front View of a typical fuel inlet lines group (A) Fuel inlet port (B) Test port for the fuel supply pressure (C) Fuel transfer pump (D) Test port location for system pressureInlet Fuel Pressure to the Transfer Pump (set at rated speed and load)

Install a 6V-3965 Fitting into Port (B) using a 214-7568 O-Ring Seal Note: The inlet pressure to the fuel transfer pump can affect overall system pressure. All filters or water separators before the transfer pump must be new and clean prior to setting the system pressure at the fuel pressure regulator.

Connect the 6V-7830 Pressure Gauge to the fitting installed in the previous step.

Set the engine to rated speed and load. Record the fuel pressure, and refer to the specifications above.Primary and Secondary Fuel Filter Differential Pressure

Primary and secondary fuel filter differential pressures are determined by the pressures from both sides of the fuel filters. This measurement will monitor fuel filter cleanliness and determine when the fuel filters require changing. Filter replacement will vary depending on fuel quality. Fuel quality can change with each shipment of fuel so monitoring the filter differential is necessary to obtain maximum filter life.Too high of a differential can cause air bubbles in the fuel system and if not corrected will lead to poor performance and injector damage. After the measurements are taken, refer to the specification above for the maximum allowable differential pressure.Primary filters or water separators should be properly sized to meet the flow requirements of the engine or engines as well as fuel being returned to the tank. Reference Table 4 for the flow requirements.

Table 4

3600 Engine Fuel Flow

Engine Model Rated Speed (rpm) Fuel Flow to Engine Fuel Flow from Engine Fuel Heat Rejection

3606 1000

41.5 L/min (11 US gpm)

32.4 L/min (8.6 US gpm)

12.5 kW (712 Btu/min)

900

38 L/min (10 US gpm)

30.0 L/min (7.9 US gpm)

11.0 kW (626 Btu/min)

750

31.5 L/min (8.3 US gpm)

24.5 L/min (6.5 US gpm)

10.5 kW (598 Btu/min)

720

30 L/min (7.9 US gpm)

23.6 L/min (6.2 US gpm)

10.0 kW (567 Btu/min)

3608 1000

41.5 L/min (11 US gpm)

30.0 L/min (7.9 US gpm)

16.7 kW (951 Btu/min)

900

38 L/min (10 US gpm)

27.6 L/min (7.3 US gpm)

14.6 kW (831 Btu/min)

750

31.5 L/min (8.3 US gpm)

22.6 L/min (6.0 US gpm)

14.0 kW (797 Btu/min)

720

30 L/min (7.9 US gpm)

21.4 L/min (5.6 US gpm)

13.3 kW (757 Btu/min)

3612 1000

78.5 L/min (20.7 US gpm)

60.1 L/min (15.9 US gpm)

25.0 kW (1423 Btu/min)

900

72 L/min (19 US gpm)

55.4 L/min (14.6 US gpm)

22.0 kW (1252 Btu/min)

750

61.2 L/min (16.2 US gpm)

47.3

Illustration 1 g03325145

Front View of a typical fuel inlet lines group (A) Fuel inlet port (B) Test port for the fuel supply pressure (C) Fuel transfer pump (D) Test port location for system pressureInlet Fuel Pressure to the Transfer Pump (set at rated speed and load)

Install a 6V-3965 Fitting into Port (B) using a 214-7568 O-Ring Seal Note: The inlet pressure to the fuel transfer pump can affect overall system pressure. All filters or water separators before the transfer pump must be new and clean prior to setting the system pressure at the fuel pressure regulator.

Connect the 6V-7830 Pressure Gauge to the fitting installed in the previous step.

Set the engine to rated speed and load. Record the fuel pressure, and refer to the specifications above.Primary and Secondary Fuel Filter Differential Pressure

Primary and secondary fuel filter differential pressures are determined by the pressures from both sides of the fuel filters. This measurement will monitor fuel filter cleanliness and determine when the fuel filters require changing. Filter replacement will vary depending on fuel quality. Fuel quality can change with each shipment of fuel so monitoring the filter differential is necessary to obtain maximum filter life.Too high of a differential can cause air bubbles in the fuel system and if not corrected will lead to poor performance and injector damage. After the measurements are taken, refer to the specification above for the maximum allowable differential pressure.Primary filters or water separators should be properly sized to meet the flow requirements of the engine or engines as well as fuel being returned to the tank. Reference Table 4 for the flow requirements.

Table 4

3600 Engine Fuel Flow

Engine Model Rated Speed (rpm) Fuel Flow to Engine Fuel Flow from Engine Fuel Heat Rejection

3606 1000

41.5 L/min (11 US gpm)

32.4 L/min (8.6 US gpm)

12.5 kW (712 Btu/min)

900

38 L/min (10 US gpm)

30.0 L/min (7.9 US gpm)

11.0 kW (626 Btu/min)

750

31.5 L/min (8.3 US gpm)

24.5 L/min (6.5 US gpm)

10.5 kW (598 Btu/min)

720

30 L/min (7.9 US gpm)

23.6 L/min (6.2 US gpm)

10.0 kW (567 Btu/min)

3608 1000

41.5 L/min (11 US gpm)

30.0 L/min (7.9 US gpm)

16.7 kW (951 Btu/min)

900

38 L/min (10 US gpm)

27.6 L/min (7.3 US gpm)

14.6 kW (831 Btu/min)

750

31.5 L/min (8.3 US gpm)

22.6 L/min (6.0 US gpm)

14.0 kW (797 Btu/min)

720

30 L/min (7.9 US gpm)

21.4 L/min (5.6 US gpm)

13.3 kW (757 Btu/min)

3612 1000

78.5 L/min (20.7 US gpm)

60.1 L/min (15.9 US gpm)

25.0 kW (1423 Btu/min)

900

72 L/min (19 US gpm)

55.4 L/min (14.6 US gpm)

22.0 kW (1252 Btu/min)

750

61.2 L/min (16.2 US gpm)

47.3