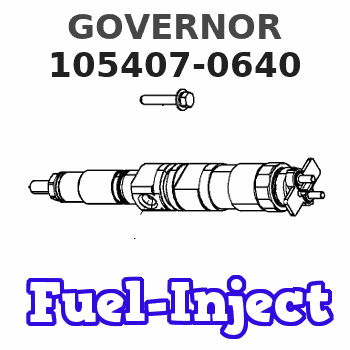

Information governor

BOSCH

F 019 Z1E 859

f019z1e859

ZEXEL

105407-0640

1054070640

Rating:

Scheme ###:

| 1. | [1] | 154000-5720 | GOVERNOR HOUSING |

| 3. | [1] | 029632-5070 | O-RING |

| 4. | [1] | 154007-2900 | CAPSULE |

| 9. | [1] | 154350-6000 | PLATE |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 12. | [1] | 154010-0500 | FLAT-HEAD SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154500-3520 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0400 | BUSHING |

| 38. | [1] | 154031-2400 | FLAT-HEAD SCREW |

| 39. | [1] | 154011-0700 | UNION NUT |

| 39. | [1] | 154011-0700 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 56. | [4] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 155404-1700 | CAP |

| 66. | [1] | 026524-3040 | GASKET |

| 82. | [2] | 029020-6270 | BLEEDER SCREW |

| 82. | [2] | 029020-6270 | BLEEDER SCREW |

| 83. | [1] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 83. | [1] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 84. | [1] | 020006-2840 | BLEEDER SCREW M6P1L28 |

| 100. | [1] | 154100-6620 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-0120 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-0300 | GOVERNOR SPRING |

| 132. | [1] | 154154-0800 | COILED SPRING |

| 135. | [1] | 154157-0120 | HEADLESS SCREW |

| 136. | [1] | 029201-2030 | UNION NUT M12P1.0H4 |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-0100 | CAP NUT |

| 140. | [1] | 154185-1320 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-0220 | SWIVELLING LEVER |

| 151. | [1] | 154204-4300 | BUSHING |

| 151. | [1] | 154204-4300 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-4400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154211-4420 | FORK LEVER |

| 174. | [1] | 154230-2920 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-4100 | TENSIONING LEVER |

| 182. | [1] | 154237-0100 | BEARING PIN |

| 190. | [1] | 154345-4920 | CONTROL LEVER |

| 191. | [1] | 154304-4720 | CONTROL LEVER |

| 191. | [1] | 154304-4720 | CONTROL LEVER |

| 192. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 201. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5020 | CONTROL LEVER |

| 208. | [1] | 154327-0200 | COILED SPRING |

| 211. | [0] | 029311-0220 | SHIM D18&10.3T0.2 |

| 211B. | [0] | 029311-0230 | SHIM D18&10.3T0.5 |

| 235. | [1] | 155412-5200 | IMPELLER WHEEL |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 154390-4300 | GASKET |

| 238. | [1] | 154390-4300 | GASKET |

| 335. | [1] | 029331-1010 | GASKET |

| 335. | [1] | 029331-1010 | GASKET |

| 336. | [1] | 154035-0500 | CAP NUT |

| 336. | [1] | 154035-0500 | CAP NUT |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Include in #1:

106662-4010

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been some instances of the following active diagnostic codes:

651-6 Engine Injector Cylinder #01 : Current Above Normal

652-6 Engine Injector Cylinder #02 : Current Above Normal

653-6 Engine Injector Cylinder #03 : Current Above Normal

654-6 Engine Injector Cylinder #04 : Current Above NormalThe engine will be derated and will be difficult to start.Solution

Follow the correct troubleshooting procedure for the active diagnostic codes. Refer to Troubleshooting, Injector Solenoid - Test.

If the troubleshooting procedure identifies suspect injectors, use the electronic service tool to generate a Product Status Report (PSR). Select the "Histogram" option when generating the PSR.

Install replacement 418-3229 Fuel Injector Gp, as required. Refer to Disassembly and Assembly, Electronic Unit Injector - Remove and Disassembly and Assembly, Electronic Unit Injector - Install.

Use 169-7372 Fluid Sampling Bottles to obtain a fuel sample from the following locations:

Machine fuel tank ( 355 mL (12 oz)

Bulk fuel supply tank ( 355 mL (12 oz)Analyze the fuel sample. The fuel samples will need to be analyzed for the following properties:

Lubricity Wear Scar - "ASTM D6079" or "ISO 12156"

Density at 15° C (59° F) - "ASTM D1298", "ASTM D4052", "ISO 3675", or "ISO 12185"

Kinematic Viscosity at 40° C (104° F) - "ASTM D445", "ISO 3448", or "ISO 3104"

Sulfur - "ASTM D4294", "ASTM D5185", "ASTM D5453", "ASTM D26222", "ISO 20846", or "ISO 20884"

Water by Distillation - "ASTM D95", "ASTM D6304", "ASTM D2709", "ASTM D1796", or "ISO3734"

Cloud Point - "ASTM D2500" or "ISO 3015"

FAME - "EN 14078", "ASTM D7806", or "ASTM D7371"

Oxidation Stability - "EN 14112"

Copper - "ASTM D7111"

Sodium - "ASTM D7111"

Zinc - "ASTM D7111"

Calcium - "ASTM D7111"

Potassium - "ASTM D7111"Provide the results of the fuel sample.

Retain any removed injectors. The injectors will be requested for return through the "Send It Back" (SIB) process.

Submit the PSR along with TIB Media number, M0085259, and CPI number 386169 through "CPI Feedback" within the Service Information Management System (SIMSi).

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been some instances of the following active diagnostic codes:

651-6 Engine Injector Cylinder #01 : Current Above Normal

652-6 Engine Injector Cylinder #02 : Current Above Normal

653-6 Engine Injector Cylinder #03 : Current Above Normal

654-6 Engine Injector Cylinder #04 : Current Above NormalThe engine will be derated and will be difficult to start.Solution

Follow the correct troubleshooting procedure for the active diagnostic codes. Refer to Troubleshooting, Injector Solenoid - Test.

If the troubleshooting procedure identifies suspect injectors, use the electronic service tool to generate a Product Status Report (PSR). Select the "Histogram" option when generating the PSR.

Install replacement 418-3229 Fuel Injector Gp, as required. Refer to Disassembly and Assembly, Electronic Unit Injector - Remove and Disassembly and Assembly, Electronic Unit Injector - Install.

Use 169-7372 Fluid Sampling Bottles to obtain a fuel sample from the following locations:

Machine fuel tank ( 355 mL (12 oz)

Bulk fuel supply tank ( 355 mL (12 oz)Analyze the fuel sample. The fuel samples will need to be analyzed for the following properties:

Lubricity Wear Scar - "ASTM D6079" or "ISO 12156"

Density at 15° C (59° F) - "ASTM D1298", "ASTM D4052", "ISO 3675", or "ISO 12185"

Kinematic Viscosity at 40° C (104° F) - "ASTM D445", "ISO 3448", or "ISO 3104"

Sulfur - "ASTM D4294", "ASTM D5185", "ASTM D5453", "ASTM D26222", "ISO 20846", or "ISO 20884"

Water by Distillation - "ASTM D95", "ASTM D6304", "ASTM D2709", "ASTM D1796", or "ISO3734"

Cloud Point - "ASTM D2500" or "ISO 3015"

FAME - "EN 14078", "ASTM D7806", or "ASTM D7371"

Oxidation Stability - "EN 14112"

Copper - "ASTM D7111"

Sodium - "ASTM D7111"

Zinc - "ASTM D7111"

Calcium - "ASTM D7111"

Potassium - "ASTM D7111"Provide the results of the fuel sample.

Retain any removed injectors. The injectors will be requested for return through the "Send It Back" (SIB) process.

Submit the PSR along with TIB Media number, M0085259, and CPI number 386169 through "CPI Feedback" within the Service Information Management System (SIMSi).