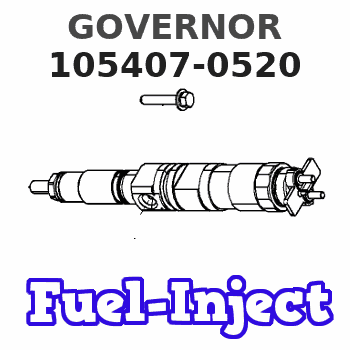

Information governor

BOSCH

F 019 Z1E 529

f019z1e529

ZEXEL

105407-0520

1054070520

MITSUBISHI

0425050860

0425050860

Rating:

Scheme ###:

| 1. | [1] | 154000-5720 | GOVERNOR HOUSING |

| 4. | [1] | 154007-1600 | CAPSULE |

| 9. | [1] | 154350-6000 | PLATE |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 12. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154500-3020 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0400 | BUSHING |

| 38. | [1] | 154031-0300 | FLAT-HEAD SCREW |

| 39. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-3100 | BLEEDER SCREW |

| 56. | [4] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 155404-1700 | CAP |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154060-7500 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 010006-3840 | BLEEDER SCREW |

| 85. | [2] | 014110-6440 | LOCKING WASHER |

| 100. | [1] | 154100-6620 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-0120 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-0200 | GOVERNOR SPRING |

| 132. | [1] | 154154-0800 | COILED SPRING |

| 135. | [1] | 154157-0120 | HEADLESS SCREW |

| 136. | [1] | 029201-2030 | UNION NUT M12P1.0H4 |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-0100 | CAP NUT |

| 140. | [1] | 154185-1320 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-7020 | SWIVELLING LEVER |

| 151. | [1] | 154204-4300 | BUSHING |

| 151. | [1] | 154204-4300 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-4400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154211-4420 | FORK LEVER |

| 174. | [1] | 154230-2920 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-4100 | TENSIONING LEVER |

| 182. | [1] | 154237-0100 | BEARING PIN |

| 190. | [1] | 154345-3720 | CONTROL LEVER |

| 191. | [1] | 154308-6200 | CONTROL LEVER |

| 192. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 201. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5120 | CONTROL LEVER |

| 208. | [1] | 154327-7300 | COILED SPRING |

| 211/1. | [0] | 029311-0520 | SHIM D20.8&10.3T0.2 |

| 211/1. | [0] | 029311-0530 | SHIM D20.8&10.3T0.25 |

| 211/1. | [0] | 029311-0540 | SHIM D20.8&10.3T0.3 |

| 211/1. | [0] | 029311-0550 | SHIM D20.8&10.3T0.35 |

| 211/1. | [0] | 029311-0560 | SHIM D20.8&10.3T0.4 |

| 211/1. | [0] | 029311-0570 | SHIM D20.8&10.3T0.5 |

| 235. | [1] | 155412-5300 | IMPELLER WHEEL |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 154390-3500 | GASKET |

| 335. | [1] | 029331-1010 | GASKET |

| 336. | [1] | 154035-0500 | CAP NUT |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Table 1

Diagnostic Trouble Codes

J1939 Code and Description CDL Code and Description

4334–20

Aftertreatment #1 DEF #1 Pressure (absolute) : Data Drifted High 3090–20

Aftertreatment #1 DEF Pressure Sensor : Data Drifted High

4334-21

Aftertreatment #1 DEF #1 Pressure (absolute) : Data Drifted Low 3090-21

Aftertreatment #1 DEF Pressure Sensor : Data Drifted Low

3361-5

Aftertreatment #1 DEF Dosing Unit : Current Below Normal 3821-5

Aftertreatment #1 Diesel Exhaust Fluid Dosing Valve Actuator : Current Below Normal

3361-6

Aftertreatment #1 DEF Dosing Unit : Current Above Normal 3821-6

Aftertreatment #1 Diesel Exhaust Fluid Dosing Valve Actuator : Current Above Normal

3516-12

Aftertreatment #1 DEF Concentration : Failure 3100-12

Aftertreatment #1 DEF Tank Fluid Quality Sensor : Failure

Table 2

Event Codes

J1939 Code and Description CDL Code and Description

5392-31

Aftertreatment Diesel Exhaust Fluid Dosing Unit Loss of Prime E1370 (2)

Aftertreatment #1 DEF Dosing Unit Loss of Prime

4334-18

Aftertreatment #1 DEF #1 Pressure (absolute) : Low - moderate severity (2) E931 (2)

Low Aftertreatment #1 DEF Pressure

4334-16

Aftertreatment #1 DEF #1 Pressure (absolute) : High - moderate severity (2) E930 (2)

High Aftertreatment #1 DEF Pressure

3516-16

Aftertreatment #1 DEF Concentration : High - moderate severity (2) E1365 (2)

High Aftertreatment #1 DEF Concentration

3516-18

Aftertreatment #1 DEF Concentration : Low - moderate severity (2) E1364 (2)

Low Aftertreatment #1 DEF Concentration

5246-15

Aftertreatment SCR Operator Inducement Severity : High - least severe (1) E1389 (1)

Aftertreatment #1 SCR Operator Inducement

5246-16

Aftertreatment SCR Operator Inducement Severity : High - moderate severity (2) E1389 (2)

Aftertreatment #1 SCR Operator Inducement

5246-0

Aftertreatment SCR Operator Inducement Severity : High - most severe (3) E1389 (3)

Aftertreatment #1 SCR Operator Inducement Ensure that DEF fluid conforms to specification ISO 22241 requirements and fluid handling, filling, and storage procedures are strictly followed.All transfer equipment and storage containers should be used exclusively for DEF and should not be reused for other fluids. For example coolants, fuels, oils, and windshield washer fluid.If contamination of the DEF system is suspected, refer to Troubleshooting, DEF Concentration is Incorrect. Ensure that the correct troubleshooting steps are followed. To test for contamination of the DEF tank, refer to Systems Operation Testing and Adjusting, Diesel Exhaust Fluid Quality - Test.If the DEF is contaminated, Caterpillar recommends that the DEF tank is flushed. Refer to Systems Operation Testing and Adjusting, Diesel Exhaust Fluid Tank - Flush for the correct procedure.