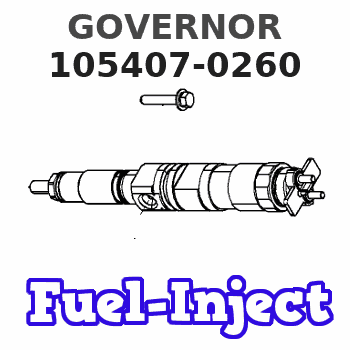

Information governor

BOSCH

F 019 Z1E 015

f019z1e015

ZEXEL

105407-0260

1054070260

ISUZU

9813204231

9813204231

Rating:

Scheme ###:

| 1. | [1] | 154000-4700 | GOVERNOR HOUSING |

| 4. | [1] | 154007-1600 | CAPSULE |

| 9. | [1] | 154350-6000 | PLATE |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 10. | [8] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 12. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 14. | [1] | 154012-1500 | BLEEDER SCREW |

| 15. | [1] | 014110-8440 | LOCKING WASHER |

| 35. | [1] | 154500-1020 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0400 | BUSHING |

| 38. | [1] | 154031-0100 | FLAT-HEAD SCREW |

| 39. | [1] | 013020-6020 | UNION NUT M6P1H5 |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-0300 | FLAT-HEAD SCREW |

| 56. | [4] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 155404-3400 | CAP |

| 66. | [1] | 026524-3040 | GASKET |

| 80. | [1] | 154060-4900 | COVER |

| 82. | [2] | 029020-6210 | BLEEDER SCREW |

| 83. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 100. | [1] | 154100-3220 | FLYWEIGHT ASSEMBLY |

| 101. | [1] | 025803-1310 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-0120 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-0400 | GOVERNOR SPRING |

| 132. | [1] | 154154-0400 | COILED SPRING |

| 135. | [1] | 154157-5220 | HEADLESS SCREW |

| 136. | [1] | 029201-2030 | UNION NUT M12P1.0H4 |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-0100 | CAP NUT |

| 140. | [1] | 154185-1320 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-6920 | SWIVELLING LEVER |

| 151. | [1] | 154204-4300 | BUSHING |

| 151. | [1] | 154204-4300 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-4400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154210-9920 | FORK LEVER |

| 174. | [1] | 154230-2920 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-4100 | TENSIONING LEVER |

| 182. | [1] | 154237-0100 | BEARING PIN |

| 190. | [1] | 154303-5220 | CONTROL LEVER |

| 191. | [1] | 154308-5800 | CONTROL LEVER |

| 192. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 195. | [1] | 154314-0200 | COILED SPRING |

| 201. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5020 | CONTROL LEVER |

| 208. | [1] | 154327-7600 | COILED SPRING |

| 211/1. | [0] | 029311-0520 | SHIM D20.8&10.3T0.2 |

| 211/1. | [0] | 029311-0530 | SHIM D20.8&10.3T0.25 |

| 211/1. | [0] | 029311-0540 | SHIM D20.8&10.3T0.3 |

| 211/1. | [0] | 029311-0550 | SHIM D20.8&10.3T0.35 |

| 211/1. | [0] | 029311-0560 | SHIM D20.8&10.3T0.4 |

| 211/1. | [0] | 029311-0570 | SHIM D20.8&10.3T0.5 |

| 236. | [1] | 154371-5600 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 900S. | [1] | 025803-1310 | WOODRUFF KEY |

| 901S. | [1] | 025803-1610 | WOODRUFF KEY |

Include in #1:

106691-1100

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

105407-0260

F 019 Z1E 015

9813204231 ISUZU

GOVERNOR

* K 14JB GOV RSV GOV

* K 14JB GOV RSV GOV

Information:

The preferred method for obtaining a representative coolant sample is to draw a sample from a coolant sampling valve that is located at a point where coolant is flowing freely. Do not take samples from any cooling system drain valves.If no suitable coolant sampling valve is available and the use of a vacuum sampling pump is required, do not use the same vacuum sampling pump for extracting oil samples that is used for extracting coolant samples. Do not draw a sample from the coolant overflow tank as it will not be representative of the coolant in the system.A small residue of either type sample may remain in the pump and may cause a false positive analysis for the sample being taken.Always use a separate pump for oil sampling and a separate pump for coolant sampling.Failure to do so may cause a false analysis which could lead to customer and dealer concerns.

New Systems, Refilled Systems, and Converted Systems

Perform an S O S coolant analysis (Level 2) at the following maintenance intervals.

Every Year

Initial 500 service hoursPerform this analysis at the interval that occurs first for new systems, for refilled systems, or for converted systems that use Cat ELC (Extended Life Coolant) or use Cat DEAC (Diesel Engine Antifreeze/Coolant). This 500 hour check will also check for any residual cleaner that may have contaminated the system.Recommended Interval for S O S Services Coolant Sample

Table 1

Recommended Interval

Type of Coolant Level 1 Level 2

Cat DEAC Every 24140 kilometers (15000 miles) (1) (2) Yearly (2) (3)

Cat ELC Optional (3) Yearly (3)

( 1 ) This is also the recommended sampling interval for all commercial coolants that meet Cat EC-1 (Engine Coolant specification - 1)

( 2 ) The recommended sampling interval for all other conventional heavy-duty coolant/antifreeze is 20120 kilometers (12500 miles).

( 3 ) The Level 2 Coolant Analysis should be performed sooner if a problem is suspected or identified.Note: Check the SCA (Supplemental Coolant Additive) of the conventional coolant at every oil change or at every 250 hours. Perform this check at the interval that occurs first.S O S Services Coolant Analysis (Level 1)

A coolant analysis (Level 1) is a test of the properties of the coolant.The following properties of the coolant are tested:

Glycol concentration for freeze protection and boil protection

Nitrite concentration

pH

Conductivity

Visual analysis of color, appearance, foaming tendency, and observation of any visible contaminants such as precipitates, oil, or fuel

Odor analysisThe results are reported, and appropriate recommendations are made.S O S Services Coolant Analysis (Level 2)

A coolant analysis (Level 2) is a comprehensive chemical evaluation of the coolant. This analysis is also a check of the overall condition of the cooling system.The S O S coolant analysis (Level 2) has the following features:

Full coolant analysis (Level 1)

Measurement of concentrations of all coolant corrosion and cavitation inhibitors

Identification of metal corrosion and of contaminants

Identification of buildup of the impurities that cause corrosion

Identification of buildup of the impurities that cause scaling

Determination of the

Have questions with 105407-0260?

Group cross 105407-0260 ZEXEL

Isuzu

Nissan-Diesel

Isuzu

Isuzu

105407-0260

F 019 Z1E 015

9813204231

GOVERNOR