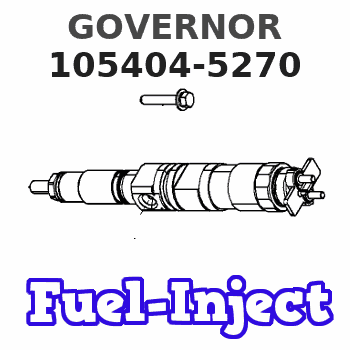

Information governor

BOSCH

9 420 610 354

9420610354

ZEXEL

105404-5270

1054045270

Rating:

Scheme ###:

| 1. | [1] | 154620-0200 | GOVERNOR HOUSING |

| 2. | [1] | 154007-2900 | CAPSULE |

| 3. | [1] | 154620-3200 | GASKET |

| 4. | [1] | 154620-1401 | COVER |

| 5. | [4] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 6. | [1] | 154621-4300 | BLEEDER SCREW |

| 7. | [1] | 154621-4100 | PLAIN WASHER |

| 8. | [1] | 154620-7900 | ADAPTOR |

| 9. | [1] | 154375-9020 | PLATE |

| 10. | [5] | 029010-6810 | BLEEDER SCREW |

| 11. | [1] | 020106-1840 | BLEEDER SCREW M6P1L18 |

| 12. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 16. | [1] | 029632-5070 | O-RING |

| 35. | [1] | 154500-0020 | GOVERNOR COVER |

| 38. | [1] | 154031-3000 | FLAT-HEAD SCREW |

| 39. | [1] | 139206-0600 | UNION NUT |

| 47. | [1] | 154036-0300 | CAPSULE |

| 51. | [2] | 139006-7100 | BLEEDER SCREW |

| 53. | [1] | 154010-0200 | FLAT-HEAD SCREW |

| 56. | [4] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 153020-5220 | STOPPING DEVICE |

| 66. | [1] | 026518-2240 | GASKET D21.9&18.2T1 |

| 80. | [1] | 154063-5100 | COVER |

| 81. | [1] | 154358-7200 | BRACKET |

| 82. | [1] | 029020-6260 | BLEEDER SCREW |

| 83. | [1] | 029020-6260 | BLEEDER SCREW |

| 84. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 86. | [1] | 020006-2040 | BLEEDER SCREW M6P1L20 4T |

| 100. | [1] | 154621-2420 | FLYWEIGHT ASSEMBLY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-0120 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-0400 | GOVERNOR SPRING |

| 132. | [1] | 154154-4600 | COILED SPRING |

| 135. | [1] | 154158-1820 | HEADLESS SCREW |

| 136. | [1] | 154011-1700 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154185-4120 | HEADLESS SCREW |

| 141. | [1] | 029201-6080 | UNION NUT |

| 150. | [1] | 154200-7020 | SWIVELLING LEVER |

| 151. | [1] | 154204-4300 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-4400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154211-4420 | FORK LEVER |

| 174. | [1] | 154620-2520 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-4100 | TENSIONING LEVER |

| 182. | [1] | 154237-1100 | BEARING PIN |

| 190. | [1] | 154342-2320 | CONTROL LEVER |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 331. | [1] | 154172-3520 | HEADLESS SCREW |

| 332. | [1] | 029201-6010 | UNION NUT |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 400. | [1] | 154620-8700 | CAPSULE |

| 401. | [1] | 154620-3100 | GASKET |

| 402. | [1] | 154620-8800 | BEARING PIN |

| 403. | [1] | 154620-8901 | PLATE |

| 404. | [1] | 010038-1840 | BLEEDER SCREW M8P1.25L18 |

| 405. | [1] | 154620-1300 | FLANGE BUSHING |

| 406. | [1] | 154620-4700 | BLEEDER SCREW |

| 407. | [2] | 014110-8440 | LOCKING WASHER |

| 407. | [2] | 014110-8440 | LOCKING WASHER |

| 408. | [2] | 014010-8140 | PLAIN WASHER D18&8.5T1.6 |

| 408. | [2] | 014010-8140 | PLAIN WASHER D18&8.5T1.6 |

| 409. | [1] | 154620-9000 | O-RING |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Test Procedure

System Operation

The engine speed switch accepts a signal from the magnetic pickup. The magnetic pickup is mounted on the engine. The speed switch determines the engine speed from the signal. The speed switch provides contacts for the following list of conditions:

Crank Terminate

Engine Oil Step Pressure

Engine Overspeed

Nine Second Time Delay

Illustration 1 g00562933

Diagram of the engine speed switchFunctional Test

Check the electrical connectors and check the wiring.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Disconnect the power supply.

Check the electrical connectors and check the wiring for damage or bad connections.

Verify that all modules are properly seated.

Verify the status of the LED on the SLC 5/04.The results of the preceding procedure are in the following list:

All of the components are fully installed. All of the components are free of corrosion. All of the components are free of damage. All of the modules are properly seated. Proceed to 2.

The components are not fully installed. The components are not free of corrosion. The components are damaged. All of the modules are not properly seated. Repair the component. Verify that the repair resolves the problem. STOP.

Verify that the engine speed switch is receiving power.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Measure the voltage on the junction box terminal strip. Measure the voltage between the following terminals: junction box terminal 6 and junction box terminal 5. The voltage should be 24 2 VDC between the junction box terminals.The results of the preceding procedure are in the following list:

The voltage is in the range. Proceed to 3.

The voltage is not in the range. Refer to Troubleshooting, "System Power". Stop.

Check the magnetic pickup.

Measure the voltage on the junction box terminal strip. Measure the voltage between the following terminals: junction box terminal 4 and junction box terminal 3. The voltage should be 5 2 VAC between the junction box terminals.The results of the preceding procedure are in the following list:

The voltage is in the range. Proceed to 4.

The voltage is not in the range. Refer to Troubleshooting, "System Power". Stop.

Test the contact for the engine speed switch.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Press the overspeed reset. This de-energizes the contact for the overspeed switch.

Measure the resistance on the junction box terminal strip. Measure the resistance between the following terminals: junction box terminal 11 and junction box terminal 12. The resistance should be zero ohms between the junction box terminals.The results of the preceding procedure are in the following list:

The resistance is good. Stop.

The resistance is not good. Replace the engine speed switch. Stop.

System Operation

The engine speed switch accepts a signal from the magnetic pickup. The magnetic pickup is mounted on the engine. The speed switch determines the engine speed from the signal. The speed switch provides contacts for the following list of conditions:

Crank Terminate

Engine Oil Step Pressure

Engine Overspeed

Nine Second Time Delay

Illustration 1 g00562933

Diagram of the engine speed switchFunctional Test

Check the electrical connectors and check the wiring.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Disconnect the power supply.

Check the electrical connectors and check the wiring for damage or bad connections.

Verify that all modules are properly seated.

Verify the status of the LED on the SLC 5/04.The results of the preceding procedure are in the following list:

All of the components are fully installed. All of the components are free of corrosion. All of the components are free of damage. All of the modules are properly seated. Proceed to 2.

The components are not fully installed. The components are not free of corrosion. The components are damaged. All of the modules are not properly seated. Repair the component. Verify that the repair resolves the problem. STOP.

Verify that the engine speed switch is receiving power.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Measure the voltage on the junction box terminal strip. Measure the voltage between the following terminals: junction box terminal 6 and junction box terminal 5. The voltage should be 24 2 VDC between the junction box terminals.The results of the preceding procedure are in the following list:

The voltage is in the range. Proceed to 3.

The voltage is not in the range. Refer to Troubleshooting, "System Power". Stop.

Check the magnetic pickup.

Measure the voltage on the junction box terminal strip. Measure the voltage between the following terminals: junction box terminal 4 and junction box terminal 3. The voltage should be 5 2 VAC between the junction box terminals.The results of the preceding procedure are in the following list:

The voltage is in the range. Proceed to 4.

The voltage is not in the range. Refer to Troubleshooting, "System Power". Stop.

Test the contact for the engine speed switch.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Press the overspeed reset. This de-energizes the contact for the overspeed switch.

Measure the resistance on the junction box terminal strip. Measure the resistance between the following terminals: junction box terminal 11 and junction box terminal 12. The resistance should be zero ohms between the junction box terminals.The results of the preceding procedure are in the following list:

The resistance is good. Stop.

The resistance is not good. Replace the engine speed switch. Stop.