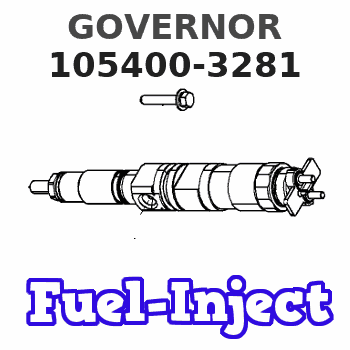

Information governor

BOSCH

F 019 Z1E 566

f019z1e566

ZEXEL

105400-3281

1054003281

Rating:

Scheme ###:

| 1. | [1] | 154000-6300 | GOVERNOR HOUSING |

| 3. | [1] | 029632-5070 | O-RING |

| 4. | [1] | 154007-2900 | CAPSULE |

| 6. | [1] | 154007-0200 | ADAPTOR |

| 7. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 9. | [1] | 154350-1900 | PLATE |

| 10. | [6] | 029010-6810 | BLEEDER SCREW |

| 12. | [1] | 154010-0100 | FLAT-HEAD SCREW |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 13. | [2] | 154011-0100 | HEXAGON NUT |

| 35. | [1] | 154500-1020 | GOVERNOR COVER |

| 35/2. | [1] | 154321-0400 | BUSHING |

| 38. | [1] | 154031-2400 | FLAT-HEAD SCREW |

| 39. | [1] | 139206-0600 | UNION NUT |

| 47. | [2] | 154036-0300 | CAPSULE |

| 47. | [2] | 154036-0300 | CAPSULE |

| 51. | [2] | 020106-5040 | BLEEDER SCREW |

| 53. | [1] | 154010-0200 | FLAT-HEAD SCREW |

| 56. | [4] | 020106-3840 | BLEEDER SCREW |

| 65. | [1] | 155404-3700 | CAP |

| 80. | [1] | 154063-1400 | COVER |

| 82. | [1] | 029020-6210 | BLEEDER SCREW |

| 83. | [1] | 029020-6240 | BLEEDER SCREW |

| 84. | [1] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 86. | [1] | 020006-1840 | BLEEDER SCREW M6P1L18 |

| 100. | [1] | 154101-0120 | FLYWEIGHT |

| 101. | [1] | 025803-1610 | WOODRUFF KEY |

| 102. | [1] | 029321-2020 | LOCKING WASHER |

| 103. | [1] | 029231-2030 | UNION NUT |

| 117. | [1] | 154123-2320 | SLIDING PIECE |

| 118/1. | [0] | 029311-0010 | SHIM D14&10.1T0.2 |

| 118/1. | [0] | 029311-0180 | SHIM D14&10.1T0.3 |

| 118/1. | [0] | 029311-0190 | SHIM D14&10.1T0.40 |

| 118/1. | [0] | 029311-0210 | SHIM D14&10.1T1 |

| 118/1. | [0] | 139410-0000 | SHIM D14.0&10.1T0.5 |

| 118/1. | [0] | 139410-0100 | SHIM D14.0&10.1T1.5 |

| 118/1. | [0] | 139410-3000 | SHIM D14&10.1T2.0 |

| 118/1. | [0] | 139410-3100 | SHIM D14&10.1T3.0 |

| 118/1. | [0] | 139410-3200 | SHIM D14&10.1T4.0 |

| 130. | [1] | 154150-2900 | GOVERNOR SPRING |

| 132. | [1] | 154154-0701 | COILED SPRING |

| 135. | [1] | 154158-0820 | HEADLESS SCREW |

| 136. | [1] | 154011-1700 | UNION NUT |

| 137. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 138. | [1] | 154159-1200 | CAP NUT |

| 140. | [1] | 154177-1920 | HEADLESS SCREW |

| 141. | [1] | 029201-6010 | UNION NUT |

| 150. | [1] | 154200-7020 | SWIVELLING LEVER |

| 151. | [1] | 154204-4300 | BUSHING |

| 152. | [2] | 029631-8020 | O-RING |

| 152. | [2] | 029631-8020 | O-RING |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 153. | [2] | 016010-1640 | LOCKING WASHER |

| 154. | [1] | 139611-0000 | PACKING RING |

| 155. | [1] | 139411-0000 | SHIM |

| 156. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 157. | [1] | 154204-4400 | BUSHING |

| 159. | [1] | 025803-1310 | WOODRUFF KEY |

| 160. | [1] | 154206-2800 | BUSHING |

| 161. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 170. | [1] | 154210-0920 | FORK LEVER |

| 174. | [1] | 154230-3920 | STRAP |

| 175. | [1] | 016010-0540 | LOCKING WASHER |

| 181. | [1] | 154236-4100 | TENSIONING LEVER |

| 182. | [1] | 154237-0100 | BEARING PIN |

| 190. | [1] | 154309-6120 | CONTROL LEVER |

| 191. | [1] | 154365-9321 | CONTROL LEVER |

| 192. | [1] | 020006-4540 | BLEEDER SCREW M6P1L45 |

| 201. | [1] | 029631-0030 | O-RING &9.8W2.3 |

| 203. | [1] | 154322-0100 | CAP |

| 207. | [1] | 154326-5020 | CONTROL LEVER |

| 208. | [1] | 154327-7600 | COILED SPRING |

| 211/1. | [0] | 029311-0520 | SHIM D20.8&10.3T0.2 |

| 211/1. | [0] | 029311-0530 | SHIM D20.8&10.3T0.25 |

| 211/1. | [0] | 029311-0540 | SHIM D20.8&10.3T0.3 |

| 211/1. | [0] | 029311-0550 | SHIM D20.8&10.3T0.35 |

| 211/1. | [0] | 029311-0560 | SHIM D20.8&10.3T0.4 |

| 211/1. | [0] | 029311-0570 | SHIM D20.8&10.3T0.5 |

| 236. | [1] | 154390-0000 | GASKET |

| 237. | [1] | 154390-0300 | GASKET |

| 238. | [1] | 029635-2020 | O-RING |

| 335. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 336. | [1] | 154035-1600 | CAP NUT |

| 400. | [1] | 154358-8600 | BRACKET |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Engine Crankshaft Turns Freely

Exhaust Smoke Can Be Seen While Starting Recommended Procedure

1. Cold Outside Temperatures ... It can be necessary to use starting aids, or to heat engine oil or coolant at temperatures below 10°F (-12°C).2. Air in Fuel System ... With air in the fuel system, the engine will normally be difficult to start, run rough, and release a large amount of white smoke. If the engine will not start, loosen a fuel injection line nut at the valve cover base. With the governor lever in the shutoff position, operate the fuel priming pump until the flow of fuel from the loosened fuel injection line is free of air. Tighten the fuel line nut. Fasten the priming pump and start the engine. If the engine still does not run smooth or releases a large amount of white smoke, loosen the fuel line nuts one at a time at the valve cover base until the fuel that comes out is free of air. Tighten the fuel line nuts. If the air can not be removed in this way, put 5 psi (35 kPa) of air pressure to the fuel tank.

Do not use more than 8 psi (55 kPa) of air pressure in the fuel tank or damage to the tank may result.

Check for leakage at the connections between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. If there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside fuel supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak.3. Low Quality Fuel ... Remove a small amount of fuel from the tank and check for water in the fuel. If there is water in the fuel, remove fuel from the tank until it is free of water and fill with a good quality fuel. Change the fuel filter and "prime" (remove the air and/or low quality fuel from the fuel system) the fuel system with the fuel priming pump. If there is no water in the fuel, prime and start the engine by using an outside source of fuel. If engine starts correctly using different fuel, remove all fuel from the tank and fill with good quality fuel. Prime the fuel system if necessary.4. Low Fuel Pressure ... Change the fuel filter. If the pressure is still low, check the bypass valve in the fuel transfer pump. Debris in the system can make the valve become stationary in the open position.5. Fuel Injection Timing Not Correct ... Check and make necessary adjustments as per Testing

Exhaust Smoke Can Be Seen While Starting Recommended Procedure

1. Cold Outside Temperatures ... It can be necessary to use starting aids, or to heat engine oil or coolant at temperatures below 10°F (-12°C).2. Air in Fuel System ... With air in the fuel system, the engine will normally be difficult to start, run rough, and release a large amount of white smoke. If the engine will not start, loosen a fuel injection line nut at the valve cover base. With the governor lever in the shutoff position, operate the fuel priming pump until the flow of fuel from the loosened fuel injection line is free of air. Tighten the fuel line nut. Fasten the priming pump and start the engine. If the engine still does not run smooth or releases a large amount of white smoke, loosen the fuel line nuts one at a time at the valve cover base until the fuel that comes out is free of air. Tighten the fuel line nuts. If the air can not be removed in this way, put 5 psi (35 kPa) of air pressure to the fuel tank.

Do not use more than 8 psi (55 kPa) of air pressure in the fuel tank or damage to the tank may result.

Check for leakage at the connections between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. If there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside fuel supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak.3. Low Quality Fuel ... Remove a small amount of fuel from the tank and check for water in the fuel. If there is water in the fuel, remove fuel from the tank until it is free of water and fill with a good quality fuel. Change the fuel filter and "prime" (remove the air and/or low quality fuel from the fuel system) the fuel system with the fuel priming pump. If there is no water in the fuel, prime and start the engine by using an outside source of fuel. If engine starts correctly using different fuel, remove all fuel from the tank and fill with good quality fuel. Prime the fuel system if necessary.4. Low Fuel Pressure ... Change the fuel filter. If the pressure is still low, check the bypass valve in the fuel transfer pump. Debris in the system can make the valve become stationary in the open position.5. Fuel Injection Timing Not Correct ... Check and make necessary adjustments as per Testing