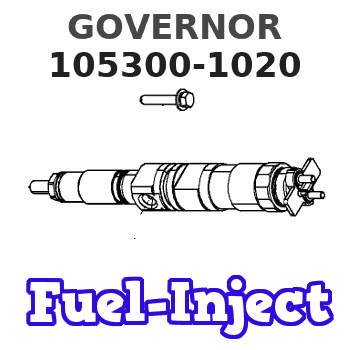

Information governor

BOSCH

F 019 Z1E 008

f019z1e008

ZEXEL

105300-1020

1053001020

ISUZU

1157200394

1157200394

Rating:

Scheme ###:

| 1. | [1] | 153000-1500 | GOVERNOR HOUSING |

| 2. | [2] | 153005-0800 | CAPSULE |

| 3. | [1] | 153006-0100 | GASKET |

| 8. | [1] | 021008-1840 | FLAT-HEAD SCREW |

| 9. | [1] | 154007-0200 | ADAPTOR |

| 13. | [4] | 021006-1540 | FLAT-HEAD SCREW |

| 21. | [1] | 153020-4020 | STOPPING DEVICE |

| 35. | [1] | 153100-5010 | GOVERNOR COVER |

| 43. | [1] | 029331-0090 | GASKET |

| 45. | [1] | 029111-0010 | CAPSULE |

| 49. | [1] | 022106-4040 | SET OF NUTS |

| 50. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 60. | [1] | 153120-2000 | LEVER SHAFT |

| 61. | [1] | 153123-0120 | CONTROL LEVER |

| 62. | [2] | 015130-2090 | TAPER PIN |

| 73. | [1] | 153141-1400 | BLEEDER SCREW |

| 74. | [1] | 029240-6010 | UNION NUT M6P1.0H5* |

| 81. | [1] | 029631-1030 | O-RING |

| 82. | [1] | 029301-1080 | PLAIN WASHER D17&11.1T1 |

| 84. | [1] | 153145-0100 | FLAT-HEAD SCREW |

| 86. | [1] | 029320-6010 | LOCKING WASHER |

| 87. | [4] | 020106-2840 | BLEEDER SCREW |

| 88. | [1] | 025803-1310 | WOODRUFF KEY |

| 115. | [1] | 153200-2520 | FLYWEIGHT ASSEMBLY |

| 115/1. | [1] | 153200-0010 | FLYWEIGHT |

| 115/11/1. | [2] | 153228-0100 | SLOTTED WASHER T0.1 |

| 115/11/1. | [2] | 153228-0200 | SLOTTED WASHER T0.2 |

| 115/11/1. | [2] | 153228-0300 | SLOTTED WASHER T0.3 |

| 115/11/1. | [2] | 153228-0400 | SLOTTED WASHER T0.4 |

| 115/12. | [2] | 153230-6600 | GOVERNOR SPRING |

| 115/13. | [2] | 153233-3400 | GOVERNOR SPRING |

| 115/14. | [2] | 153236-6600 | GOVERNOR SPRING |

| 115/17. | [2] | 153243-0100 | SLOTTED WASHER |

| 115/18. | [2] | 153244-0100 | UNION NUT |

| 115/30. | [2] | 156011-0100 | FELT |

| 115/31. | [4] | 153251-0300 | DAMPER |

| 115/32/1. | [2] | 153254-0100 | SHIM D17.9&12.5T2.0 |

| 115/32/1. | [2] | 153254-0200 | SHIM D17.9&12.5T1.9 |

| 115/32/1. | [2] | 153254-0300 | SHIM D17.9&12.5T1.8 |

| 115/32/1. | [2] | 153254-0400 | SHIM D17.9&12.5T1.7 |

| 115/32/1. | [2] | 153254-0500 | SHIM D17.9&12.5T1.75 |

| 115/32/1. | [2] | 153254-0600 | SHIM D17.9&12.5T1.85 |

| 115/33. | [1] | 153255-0100 | HEXAGON NUT |

| 115/34. | [1] | 153256-0300 | BUSHING |

| 115/36. | [2] | 029020-6090 | BLEEDER SCREW |

| 115/41. | [1] | 153260-0120 | BUSHING |

| 115/42. | [1] | 153270-0100 | BLEEDER SCREW |

| 115/43. | [2] | 029220-6010 | UNION NUT |

| 115/44. | [1] | 153271-0100 | TAB WASHER |

| 115/45. | [0] | 029312-5120 | SHIM D33&25T0.2 |

| 115/45. | [0] | 029312-6150 | SHIM D33&26T0.5 |

| 116. | [1] | 025803-1610 | WOODRUFF KEY |

| 117. | [1] | 153300-0100 | TERMINAL STUD |

| 118/1. | [0] | 139411-0700 | SHIM D22&11T0.7 |

| 118/1. | [0] | 153305-0100 | SHIM D22&11T0.5 |

| 118/1. | [0] | 153305-0200 | SHIM D22&11T0.4 |

| 118/1. | [0] | 153305-0300 | SHIM D22&11T0.3 |

| 118/1. | [0] | 153305-0400 | SHIM D22&11T0.25 |

| 118/1. | [0] | 153305-0500 | SHIM D22&11T1.0 |

| 118/1. | [0] | 153305-0600 | SHIM D22&11T1.1 |

| 118/1. | [0] | 153305-0700 | SHIM D22&11T2.0 |

| 118/1. | [0] | 153305-1300 | SHIM D22&11T0.951 |

| 118/1. | [0] | 153305-1400 | SHIM D22&11T0.95 |

| 119. | [1] | 153312-0100 | PLAIN WASHER |

| 120. | [1] | 023630-8410 | LOCKING WASHER |

| 121. | [1] | 023130-8020 | UNION NUT |

| 122. | [1] | 025520-2010 | SPLIT PIN |

| 123. | [1] | 153316-0100 | CROSS-HEAD |

| 141. | [1] | 153401-0100 | COILED SPRING |

| 146. | [1] | 153405-0120 | STRAP |

| 147. | [1] | 153406-0400 | BLEEDER SCREW |

| 148. | [2] | 014110-5440 | LOCKING WASHER |

| 149. | [2] | 013020-5220 | UNION NUT M5P0.8H4 |

| 151. | [1] | 025520-1510 | SPLIT PIN |

| 152. | [1] | 153410-1300 | VARIABLE-FULCRUM LEVER |

| 153. | [1] | 025060-1610 | BEARING PIN |

| 154. | [1] | 025515-1510 | SPLIT PIN |

| 165. | [1] | 153500-6020 | CONTROL LEVER |

| 179. | [1] | 154350-9000 | GASKET |

| 180. | [1] | 154390-1200 | GASKET |

| 191. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 191B. | [0] | 029311-1090 | SHIM D16&11T0.3 |

| 192. | [2] | 029010-6810 | BLEEDER SCREW |

| 193. | [2] | 029300-6200 | PLAIN WASHER D12&6.4T1.2 |

| 220. | [1] | 154351-7820 | PLATE |

| 224. | [1] | 153508-9220 | CONTROL LEVER |

| 225. | [1] | 154332-0500 | COILED SPRING |

| 227. | [1] | 029010-6310 | BLEEDER SCREW |

| 230. | [1] | 153402-0100 | CONNECTOR |

| 231. | [1] | 010065-1640 | BLEEDER SCREW M5P0.8L16 4T |

| 232. | [1] | 020106-2240 | BLEEDER SCREW |

| 237. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 238. | [1] | 131318-0200 | SPACER BUSHING |

| 239. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 240. | [1] | 153556-2000 | BRACKET |

| 241. | [2] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

Include in #1:

101601-4060

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

105300-1020

F 019 Z1E 008

1157200394 ISUZU

GOVERNOR

* K

* K

Information:

Table 4 is an example for using the equation that is in Table 3.

Table 4

Example of the Equation for the Addition of Cat SCA To Water For Maintenance

Total Volume of the Cooling System (V) Multiplication

Factor Amount of Cat SCA that is Required (X)

946 L

(250 US gal) × 0.023 22 L

(6 US gal) Note: Specific engine applications may require maintenance practices to be periodically evaluated to maintain the engine cooling system properly.Cleaning the System of Heavy-Duty Coolant/Antifreeze

Before Cat SCA can be effective, the cooling system must be free from rust, scale, and other deposits. Preventive cleaning helps avoid downtime caused by expensive out-of-service cleaning required for extremelydirty and neglected cooling systems.Cat Cooling System Cleaners

Dissolves or depresses mineral scales, corrosion products, light oil contaminations, and sludges

Cleans the cooling system after used coolant is drained or before the cooling system is filled with new coolant

Cleans the cooling system whenever the coolant is contaminated or whenever the coolant is foaming

The “Standard” version of the Cat Cooling System Cleaners clean the cooling system while still in service.

Reduces downtime and cleaning costs

Helps avoid costly repairs from pitting and other internal problems caused by improper cooling system maintenance

Can be used with glycol-based antifreeze

For the recommended service interval, refer to the Operation and Maintenance Manual, "Maintenance Interval Schedule" for your engine.Cat Standard Cooling System Cleaners are designed to clean the cooling system of harmful scale and corrosion without removing the engine from service. The cleaners, both “Standard” and “Quick Flush” can be used in all Cat engine cooling systems. Consult your Cat dealer for part numbers.Note: These cleaners must not be used in systems that have been neglected or that have heavy scale buildup. These systems require a stronger commercial solvent that is available from local distributors.Prior to performing a cleaning of the cooling system, take a 1-liter (1-quart) sample of coolant from the engine while in operation into a clear container. Take the sample shortly after start-up while the coolant is not yet hot. The coolant should be adequately mixed by the water pump. Allow the sample

Table 4

Example of the Equation for the Addition of Cat SCA To Water For Maintenance

Total Volume of the Cooling System (V) Multiplication

Factor Amount of Cat SCA that is Required (X)

946 L

(250 US gal) × 0.023 22 L

(6 US gal) Note: Specific engine applications may require maintenance practices to be periodically evaluated to maintain the engine cooling system properly.Cleaning the System of Heavy-Duty Coolant/Antifreeze

Before Cat SCA can be effective, the cooling system must be free from rust, scale, and other deposits. Preventive cleaning helps avoid downtime caused by expensive out-of-service cleaning required for extremelydirty and neglected cooling systems.Cat Cooling System Cleaners

Dissolves or depresses mineral scales, corrosion products, light oil contaminations, and sludges

Cleans the cooling system after used coolant is drained or before the cooling system is filled with new coolant

Cleans the cooling system whenever the coolant is contaminated or whenever the coolant is foaming

The “Standard” version of the Cat Cooling System Cleaners clean the cooling system while still in service.

Reduces downtime and cleaning costs

Helps avoid costly repairs from pitting and other internal problems caused by improper cooling system maintenance

Can be used with glycol-based antifreeze

For the recommended service interval, refer to the Operation and Maintenance Manual, "Maintenance Interval Schedule" for your engine.Cat Standard Cooling System Cleaners are designed to clean the cooling system of harmful scale and corrosion without removing the engine from service. The cleaners, both “Standard” and “Quick Flush” can be used in all Cat engine cooling systems. Consult your Cat dealer for part numbers.Note: These cleaners must not be used in systems that have been neglected or that have heavy scale buildup. These systems require a stronger commercial solvent that is available from local distributors.Prior to performing a cleaning of the cooling system, take a 1-liter (1-quart) sample of coolant from the engine while in operation into a clear container. Take the sample shortly after start-up while the coolant is not yet hot. The coolant should be adequately mixed by the water pump. Allow the sample

Have questions with 105300-1020?

Group cross 105300-1020 ZEXEL

Isuzu

105300-1020

F 019 Z1E 008

1157200394

GOVERNOR