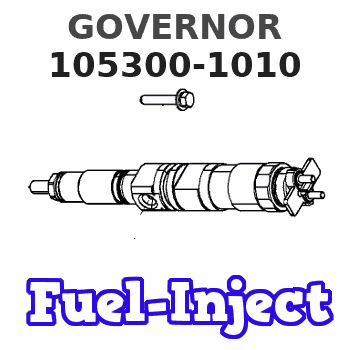

Information governor

BOSCH

F 019 Z1E 007

f019z1e007

ZEXEL

105300-1010

1053001010

ISUZU

1157200422

1157200422

Rating:

Scheme ###:

| 1. | [1] | 153000-0700 | GOVERNOR HOUSING |

| 2. | [2] | 153005-0800 | CAPSULE |

| 3. | [1] | 153006-0100 | GASKET |

| 8. | [1] | 021008-1840 | FLAT-HEAD SCREW |

| 9. | [1] | 154007-0200 | ADAPTOR |

| 13. | [4] | 021006-1540 | FLAT-HEAD SCREW |

| 21. | [1] | 153020-4020 | STOPPING DEVICE |

| 35. | [1] | 153100-5010 | GOVERNOR COVER |

| 43. | [1] | 029331-0090 | GASKET |

| 45. | [1] | 029111-0010 | CAPSULE |

| 49. | [1] | 022106-4040 | SET OF NUTS |

| 50. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 60. | [1] | 153120-2000 | LEVER SHAFT |

| 61. | [1] | 153123-0120 | CONTROL LEVER |

| 62. | [2] | 015130-2090 | TAPER PIN |

| 73. | [1] | 153141-1000 | BLEEDER SCREW |

| 74. | [1] | 029240-6010 | UNION NUT M6P1.0H5* |

| 81. | [1] | 029631-1030 | O-RING |

| 82. | [1] | 029301-1080 | PLAIN WASHER D17&11.1T1 |

| 84. | [1] | 153145-0100 | FLAT-HEAD SCREW |

| 86. | [1] | 029320-6010 | LOCKING WASHER |

| 87. | [4] | 020106-2840 | BLEEDER SCREW |

| 88. | [1] | 025803-1310 | WOODRUFF KEY |

| 115. | [1] | 153200-3120 | FLYWEIGHT ASSEMBLY |

| 115/1. | [1] | 153200-0010 | FLYWEIGHT |

| 115/11/1. | [2] | 153228-0100 | SLOTTED WASHER T0.1 |

| 115/11/1. | [2] | 153228-0200 | SLOTTED WASHER T0.2 |

| 115/11/1. | [2] | 153228-0300 | SLOTTED WASHER T0.3 |

| 115/11/1. | [2] | 153228-0400 | SLOTTED WASHER T0.4 |

| 115/12. | [2] | 153230-6600 | GOVERNOR SPRING |

| 115/13. | [2] | 153233-2800 | GOVERNOR SPRING |

| 115/14. | [2] | 153236-6000 | GOVERNOR SPRING |

| 115/17. | [2] | 153243-0100 | SLOTTED WASHER |

| 115/18. | [2] | 153244-0100 | UNION NUT |

| 115/30. | [2] | 156011-0100 | FELT |

| 115/31. | [4] | 153251-0300 | DAMPER |

| 115/32/1. | [2] | 153254-0100 | SHIM D17.9&12.5T2.0 |

| 115/32/1. | [2] | 153254-0200 | SHIM D17.9&12.5T1.9 |

| 115/32/1. | [2] | 153254-0300 | SHIM D17.9&12.5T1.8 |

| 115/32/1. | [2] | 153254-0400 | SHIM D17.9&12.5T1.7 |

| 115/32/1. | [2] | 153254-0500 | SHIM D17.9&12.5T1.75 |

| 115/32/1. | [2] | 153254-0600 | SHIM D17.9&12.5T1.85 |

| 115/33. | [1] | 153255-0100 | HEXAGON NUT |

| 115/34. | [1] | 153256-0300 | BUSHING |

| 115/36. | [2] | 029020-6090 | BLEEDER SCREW |

| 115/41. | [1] | 153260-0120 | BUSHING |

| 115/42. | [1] | 153270-0100 | BLEEDER SCREW |

| 115/43. | [2] | 029220-6010 | UNION NUT |

| 115/44. | [1] | 153271-0100 | TAB WASHER |

| 115/45. | [0] | 029312-5120 | SHIM D33&25T0.2 |

| 115/45. | [0] | 029312-6150 | SHIM D33&26T0.5 |

| 116. | [1] | 025803-1610 | WOODRUFF KEY |

| 117. | [1] | 153300-0100 | TERMINAL STUD |

| 118/1. | [0] | 139411-0700 | SHIM D22&11T0.7 |

| 118/1. | [0] | 153305-0100 | SHIM D22&11T0.5 |

| 118/1. | [0] | 153305-0200 | SHIM D22&11T0.4 |

| 118/1. | [0] | 153305-0300 | SHIM D22&11T0.3 |

| 118/1. | [0] | 153305-0400 | SHIM D22&11T0.25 |

| 118/1. | [0] | 153305-0500 | SHIM D22&11T1.0 |

| 118/1. | [0] | 153305-0600 | SHIM D22&11T1.1 |

| 118/1. | [0] | 153305-0700 | SHIM D22&11T2.0 |

| 118/1. | [0] | 153305-1300 | SHIM D22&11T0.951 |

| 118/1. | [0] | 153305-1400 | SHIM D22&11T0.95 |

| 119. | [1] | 153312-0100 | PLAIN WASHER |

| 120. | [1] | 023630-8410 | LOCKING WASHER |

| 121. | [1] | 023130-8020 | UNION NUT |

| 122. | [1] | 025520-2010 | SPLIT PIN |

| 123. | [1] | 153316-0100 | CROSS-HEAD |

| 141. | [1] | 153401-0100 | COILED SPRING |

| 146. | [1] | 153405-0120 | STRAP |

| 147. | [1] | 153406-0400 | BLEEDER SCREW |

| 148. | [2] | 014110-5440 | LOCKING WASHER |

| 149. | [2] | 013020-5220 | UNION NUT M5P0.8H4 |

| 151. | [1] | 025520-1510 | SPLIT PIN |

| 152. | [1] | 153410-1300 | VARIABLE-FULCRUM LEVER |

| 153. | [1] | 025060-1610 | BEARING PIN |

| 154. | [1] | 025515-1510 | SPLIT PIN |

| 165. | [1] | 153500-6020 | CONTROL LEVER |

| 179. | [1] | 154350-9000 | GASKET |

| 180. | [1] | 154390-1200 | GASKET |

| 191. | [0] | 029311-1070 | SHIM D16&11T0.5 |

| 191B. | [0] | 029311-1090 | SHIM D16&11T0.3 |

| 192. | [2] | 029010-6810 | BLEEDER SCREW |

| 193. | [2] | 029300-6200 | PLAIN WASHER D12&6.4T1.2 |

| 220. | [1] | 154351-7820 | PLATE |

| 224. | [1] | 153508-9120 | CONTROL LEVER |

| 225. | [1] | 154332-0500 | COILED SPRING |

| 227. | [1] | 029010-6310 | BLEEDER SCREW |

| 230. | [1] | 153402-0100 | CONNECTOR |

| 231. | [1] | 010065-1640 | BLEEDER SCREW M5P0.8L16 4T |

| 232. | [1] | 020106-2240 | BLEEDER SCREW |

| 237. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 238. | [1] | 131318-0200 | SPACER BUSHING |

| 239. | [0] | 154206-0200 | PLAIN WASHER D19.5&11.2T1.0 |

| 240. | [1] | 153556-2000 | BRACKET |

| 241. | [2] | 020006-1240 | BLEEDER SCREW M6P1L12 4T |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Cat ELC

Caterpillar provides Cat ELC (Extended Life Coolant) for use in the following applications:

Heavy-duty diesel engines

Automotive applicationsWhen Cat ELC is compared to conventional coolants, the Cat ELC anti-corrosion package is based on a different additive system. Cat ELC has been formulated with the correct amounts of additives. Superior corrosion protection is provided for all metals that are in engine cooling systems.Cat ELC extends the service life of the coolant to 12000 service hours or 6 years. Cat ELC does not require the frequent addition of the Cat ELC Extender additive. An Extender is the only additional maintenance that is needed at 6000 service hours or one half of the Cat ELC service life.Cat ELC is available in a 1:1 premixed cooling solution with distilled water. The premixed Cat ELC provides freeze protection to −37 °C (−34 °F). The premixed Cat ELC is recommended for the initial fill of the cooling system. The premixed Cat ELC is also recommended for topping off the cooling system.Cat ELC Concentrate is also available. Cat ELC Concentrate can be used to lower the freezing point to −52 °C (−62 °F) for arctic conditions.Containers of several sizes are available. Refer to this Special Publication, "Coolant Recommendations" article for available quantities and part numbers.Note: Cat ELC can be used in most diesel and gasoline OEM engines. Cat ELC meets

Caterpillar provides Cat ELC (Extended Life Coolant) for use in the following applications:

Heavy-duty diesel engines

Automotive applicationsWhen Cat ELC is compared to conventional coolants, the Cat ELC anti-corrosion package is based on a different additive system. Cat ELC has been formulated with the correct amounts of additives. Superior corrosion protection is provided for all metals that are in engine cooling systems.Cat ELC extends the service life of the coolant to 12000 service hours or 6 years. Cat ELC does not require the frequent addition of the Cat ELC Extender additive. An Extender is the only additional maintenance that is needed at 6000 service hours or one half of the Cat ELC service life.Cat ELC is available in a 1:1 premixed cooling solution with distilled water. The premixed Cat ELC provides freeze protection to −37 °C (−34 °F). The premixed Cat ELC is recommended for the initial fill of the cooling system. The premixed Cat ELC is also recommended for topping off the cooling system.Cat ELC Concentrate is also available. Cat ELC Concentrate can be used to lower the freezing point to −52 °C (−62 °F) for arctic conditions.Containers of several sizes are available. Refer to this Special Publication, "Coolant Recommendations" article for available quantities and part numbers.Note: Cat ELC can be used in most diesel and gasoline OEM engines. Cat ELC meets