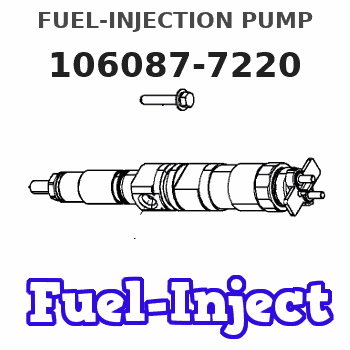

Information fuel-injection pump

BOSCH

9 410 614 265

9410614265

ZEXEL

106087-7220

1060877220

HINO

221003050A

221003050a

Rating:

Scheme ###:

| 1. | [1] | 134064-0120 | PUMP HOUSING |

| 1/30. | [3] | 029040-6020 | STUD |

| 1/45. | [1] | 134311-0000 | SPACER RING |

| 1/50. | [16] | 134138-0000 | STUD |

| 7. | [8] | 134144-7920 | PLUNGER-AND-BARREL ASSY |

| 7/1. | [1] | 134131-1920 | FLANGE BUSHING |

| 7/2. | [1] | 134151-5920 | PLUNGER-AND-BARREL ASSY |

| 7/3. | [1] | 134110-7020 | DELIVERY-VALVE ASSEMBLY |

| 7/4. | [1] | 134116-3521 | FITTING |

| 7/5. | [1] | 139722-0400 | O-RING |

| 7/7. | [1] | 134112-0500 | COMPRESSION SPRING |

| 7/8. | [1] | 134115-0100 | GASKET |

| 7/9. | [1] | 029302-0140 | PLAIN WASHER |

| 7/10. | [1] | 134135-0400 | CAPSULE |

| 7/11. | [1] | 029602-0010 | LOCKING WASHER |

| 7/13. | [1] | 139729-0400 | O-RING |

| 7/14. | [1] | 139715-0400 | O-RING |

| 7/15. | [1] | 139715-0400 | O-RING |

| 23/1. | [0] | 139400-0900 | SHIM T0.500 |

| 23/1. | [0] | 139400-0900 | SHIM T0.500 |

| 23/1. | [0] | 139400-1000 | SHIM T0.525 |

| 23/1. | [0] | 139400-1100 | SHIM T0.550 |

| 23/1. | [0] | 139400-1200 | SHIM T0.575 |

| 23/1. | [0] | 139400-1300 | SHIM T0.600 |

| 23/1. | [0] | 139400-1400 | SHIM T0.625 |

| 23/1. | [0] | 139400-1500 | SHIM T0.650 |

| 23/1. | [0] | 139400-1600 | SHIM T0.675 |

| 23/1. | [0] | 139400-1700 | SHIM T0.700 |

| 23/1. | [0] | 139400-1800 | SHIM T0.725 |

| 23/1. | [0] | 139400-1900 | SHIM T0.750 |

| 23/1. | [0] | 139400-2000 | SHIM T0.775 |

| 23/1. | [0] | 139400-2100 | SHIM T0.800 |

| 23/1. | [0] | 139400-2200 | SHIM T0.825 |

| 23/1. | [0] | 139400-2300 | SHIM T0.850 |

| 23/1. | [0] | 139400-2400 | SHIM T0.875 |

| 23/1. | [0] | 139400-2500 | SHIM T0.900 |

| 23/1. | [0] | 139400-2600 | SHIM T0.925 |

| 23/1. | [0] | 139400-2700 | SHIM T0.950 |

| 23/1. | [0] | 139400-2800 | SHIM T0.975 |

| 23/1. | [0] | 139400-2900 | SHIM T1.000 |

| 23/1. | [0] | 139400-3000 | SHIM T1.025 |

| 23/1. | [0] | 139400-3100 | SHIM T1.050 |

| 23/1. | [0] | 139400-3200 | SHIM T1.075 |

| 23/1. | [0] | 139400-3300 | SHIM T1.100 |

| 23/1. | [0] | 139400-3400 | SHIM T1.125 |

| 23/1. | [0] | 139400-3500 | SHIM T1.150 |

| 23/1. | [0] | 139400-3600 | SHIM T1.175 |

| 23/1. | [0] | 139400-3700 | SHIM T1.200 |

| 23/1. | [0] | 139400-3800 | SHIM T1.225 |

| 23/1. | [0] | 139400-3900 | SHIM T1.250 |

| 23/1. | [0] | 139400-4000 | SHIM T1.275 |

| 23/1. | [0] | 139400-4100 | SHIM T1.300 |

| 23/1. | [0] | 139400-4200 | SHIM T1.325 |

| 23/1. | [0] | 139400-4300 | SHIM T1.350 |

| 23/1. | [0] | 139400-4400 | SHIM T1.375 |

| 23/1. | [0] | 139400-4500 | SHIM T1.400 |

| 23/1. | [0] | 139400-4600 | SHIM T1.425 |

| 23/1. | [0] | 139400-4700 | SHIM T1.450 |

| 23/1. | [0] | 139400-4800 | SHIM T1.475 |

| 23/1. | [0] | 139400-4900 | SHIM T1.500 |

| 23/1. | [0] | 139400-5000 | SHIM T1.525 |

| 23/1. | [0] | 139400-5100 | SHIM T1.550 |

| 23/1. | [0] | 139400-5200 | SHIM T1.575 |

| 23/1. | [0] | 139400-5300 | SHIM T1.600 |

| 23/1. | [0] | 139400-5400 | SHIM T1.625 |

| 23/1. | [0] | 139400-5500 | SHIM T1.650 |

| 23/1. | [0] | 139400-5600 | SHIM T1.675 |

| 23/1. | [0] | 139400-5700 | SHIM T1.700 |

| 23/1. | [0] | 139400-5800 | SHIM T1.725 |

| 23/1. | [0] | 139400-5900 | SHIM T1.750 |

| 23/1. | [0] | 139400-6000 | SHIM T1.775 |

| 23/1. | [0] | 139400-6100 | SHIM T1.800 |

| 23/1. | [0] | 139400-6200 | SHIM T1.825 |

| 23/1. | [0] | 139400-6300 | SHIM T1.850 |

| 23/1. | [0] | 139400-6400 | SHIM T1.875 |

| 23/1. | [0] | 139400-6500 | SHIM T1.900 |

| 23/1. | [0] | 139400-6600 | SHIM T1.925 |

| 23/1. | [0] | 139400-6700 | SHIM T1.950 |

| 23/1. | [0] | 139400-6800 | SHIM T1.975 |

| 24. | [16] | 134132-0300 | PLAIN WASHER D20&11T2.5 |

| 26. | [16] | 013021-0040 | UNION NUT M10P1.5H8 |

| 30. | [2] | 134001-0000 | BUSHING |

| 30. | [2] | 134001-0000 | BUSHING |

| 32. | [1] | 134258-2400 | CONTROL RACK |

| 33. | [1] | 024030-2030 | BEARING PIN |

| 34. | [1] | 134222-0000 | BUSHING |

| 41. | [8] | 134241-0320 | CONTROL SLEEVE |

| 43. | [8] | 134216-0000 | SLOTTED WASHER |

| 44. | [8] | 134215-0700 | COILED SPRING |

| 45. | [8] | 134217-0500 | SLOTTED WASHER |

| 47. | [8] | 134200-0420 | TAPPET |

| 47/2. | [1] | 134204-0100 | ROLLER |

| 47/3. | [1] | 134205-0000 | BUSHING |

| 47/4. | [1] | 134203-0000 | BEARING PIN |

| 47/5. | [1] | 131206-0500 | SLIDER |

| 59. | [1] | 016650-2230 | BEARING PLATE |

| 64/1. | [0] | 134303-0000 | SHIM D59.8&43T1.2 |

| 64/1. | [0] | 134303-0100 | SHIM D59.8&43T1.5 |

| 64/1. | [0] | 134303-0200 | SHIM D59.8&43T1.8 |

| 64/1. | [0] | 134303-0300 | SHIM D59.8&43T2.0 |

| 64/1. | [0] | 134303-0400 | SHIM D59.8&43T0.6 |

| 71. | [1] | 134381-3500 | CAMSHAFT |

| 73. | [2] | 134306-1200 | BEARING SHELL |

| 74. | [1] | 134306-0600 | BEARING SHELL |

| 75. | [6] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 75. | [6] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 79. | [1] | 016650-2230 | BEARING PLATE |

| 80. | [1] | 134316-4420 | COVER |

| 80/2. | [1] | 139634-0100 | PACKING RING |

| 80/3. | [1] | 139699-0100 | PACKING RING |

| 82/1. | [0] | 134314-0000 | SHIM T0.1 |

| 82/1. | [0] | 134314-0100 | SHIM T0.12 |

| 82/1. | [0] | 134314-0200 | SHIM T0.14 |

| 82/1. | [0] | 134314-0300 | SHIM T0.16 |

| 82/1. | [0] | 134314-0400 | SHIM T0.18 |

| 82/1. | [0] | 134314-0500 | SHIM T0.3 |

| 82/1. | [0] | 134314-0600 | SHIM T0.5 |

| 83. | [1] | 029635-5010 | O-RING |

| 85. | [1] | 134043-0700 | COVER |

| 86. | [1] | 134042-1500 | GASKET |

| 87. | [14] | 012206-1640 | FLAT-HEAD SCREW M6P1L16 |

| 88. | [1] | 134045-0100 | CAPSULE |

| 89. | [1] | 026524-2940 | GASKET D28.9&24.3T2 |

| 93. | [3] | 139206-0400 | UNION NUT |

| 95. | [1] | 131041-0800 | GASKET |

| 96. | [8] | 134047-0000 | CAPSULE |

| 118. | [1] | 134496-3000 | POINTER |

| 119. | [2] | 010206-1240 | HEX-SOCKET-HEAD CAP SCREW M6P1L12 |

| 147. | [1] | 139810-0700 | EYE BOLT |

| 148. | [3] | 139510-0300 | GASKET |

| 152. | [1] | 029731-4630 | EYE BOLT |

| 153. | [2] | 139514-0300 | GASKET |

| 157. | [1] | 139814-0400 | EYE BOLT |

| 158. | [3] | 139514-0300 | GASKET |

| 162. | [1] | 134424-0820 | OVER FLOW VALVE |

| 163. | [3] | 139514-0300 | GASKET |

| 167. | [1] | 029111-4120 | SCREW PLUG M14P1.5L13 |

| 168. | [1] | 139514-0300 | GASKET |

| 250. | [1] | 134311-0420 | PLATE |

| 250/2. | [1] | 139642-0100 | PACKING RING |

| 251. | [4] | 139006-3101 | BLEEDER SCREW |

| 252. | [4] | 016430-0070 | BACKUP RING |

| 253. | [4] | 016500-0750 | O-RING |

| 254. | [1] | 134400-0500 | ADAPTOR |

| 256. | [1] | 029731-4680 | EYE BOLT |

| 257. | [2] | 139514-0300 | GASKET |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

C175 Engine References

Reference: Troubleshooting, M0069788, "C175 Tier 4 Final Engines for Off-Highway Trucks"Reference: Testing and Adjusting, M0069782, "C175 Tier 4 Final Engines for Off-Highway Trucks"Reference: Disassembly and Assembly, M0080117, "C175 Tier 4 Final Engines for Caterpillar Built Machines"3500 Engine References

Reference: Troubleshooting, M0080819, "3516E Engine for Tier 4 Final 994K Wheel Loaders"Reference: Testing and Adjusting, M0080815, "3516E Engine for Tier 4 Final 994K Wheel Loaders"Reference: Disassembly and Assembly, M0092351, "3516E Engines for Caterpillar Built Machines"Procedure

Note: If failed parts need to be shipped back, please cap off the ports using the caps from the new part.

The DEF injector troubleshooting return form is required and included with failed part returns documenting what was found that led to DEF injector replacement. Attach photos of the DEF injector tip and the mount area along with a Product Status Report to the Service Information Management System claim.

Determine the diagnostic code. ____________________

Troubleshoot the code found using the appropriate troubleshooting manual.

When the troubleshooting procedure requests the DEF quality check, DEF injector resistance measurement, or Dosing Accuracy Test, document the results in Tables 1, 2, and 3.

Table 1

DEF Quality Results

Step Instruction Completed (Yes/No) Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test (include photo of test strip if possible)

3 DEF Concentration Test

% at 20° C (68° F)

Illustration 1 g06371891

Diesel Exhaust Fluid (DEF) Injector Resistance Measurement

Table 2

Injector Resistance Measurement

Step Instruction Completed (Yes/No) Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injector from the applicable harness.

3 Inspect the connector for damage or debris (if damaged take photo).

4 Measure the temperature of the injector (aluminum body). ° C (° F)

5 Connect 2 of the 398-4987 Probe to the DEF injector. The connectors must be used to prevent damage to the DEF injector connector.

6 Measure the resistance of the DEF injector.

Ohms

Table 3

Dosing Accuracy Test

Step Instruction Completed (Yes/No) Units

1 Follow the Testing and Adjusting, Aftertreatment SCR System Dosing - Test.

2 Take a photograph of the DEF injector mount, gasket, and bolts on the SCR inlet prior to removal.

3 Remove the injector from the SCR inlet.

4 Take a photograph of the DEF injector mount on the SCR inlet and the tip of the DEF injector. ° C (° F)

5 Run the DEF System Dosing Accuracy test through Cat ET.

6 Use a beaker to measure the amount of fluid from the dosing test. mL (oz)

7 Repeat the test to verify consistency.

mL (oz)

8 Install the injector back onto the SCR Inlet if instructed per the Troubleshooting Guide Results/Comments

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________