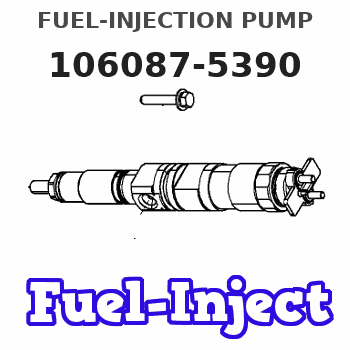

Information fuel-injection pump

BOSCH

9 410 613 025

9410613025

ZEXEL

106087-5390

1060875390

Rating:

Scheme ###:

| 1. | [1] | 134050-1120 | PUMP HOUSING |

| 1/30. | [3] | 029040-6020 | STUD |

| 1/45. | [1] | 134311-0000 | SPACER RING |

| 1/50. | [16] | 134138-0000 | STUD |

| 7. | [8] | 134142-5520 | PLUNGER-AND-BARREL ASSY |

| 7/1. | [8] | 134131-1020 | FLANGE BUSHING |

| 7/2. | [8] | 134101-8620 | PLUNGER-AND-BARREL ASSY |

| 7/3. | [8] | 134110-5420 | DELIVERY-VALVE ASSEMBLY |

| 7/4. | [8] | 134116-3200 | FITTING |

| 7/5. | [8] | 029632-2070 | O-RING |

| 7/6. | [8] | 134117-1400 | FILLER PIECE |

| 7/7. | [8] | 134112-0600 | COILED SPRING |

| 7/8. | [8] | 134115-0100 | GASKET |

| 7/9. | [8] | 029302-0140 | PLAIN WASHER |

| 7/10. | [8] | 134135-0200 | CAPSULE |

| 7/11. | [8] | 029602-0010 | LOCKING WASHER |

| 7/12. | [8] | 134137-0000 | SPACER RING |

| 7/13. | [8] | 029632-9030 | O-RING |

| 7/14. | [8] | 029631-5020 | O-RING |

| 7/15. | [8] | 029631-5020 | O-RING |

| 23/1. | [0] | 134139-0000 | SHIM T0.5 |

| 23/1. | [0] | 134139-0100 | SHIM T0.6 |

| 23/1. | [0] | 134139-0200 | SHIM T0.7 |

| 23/1. | [0] | 134139-0300 | SHIM T0.8 |

| 23/1. | [0] | 134139-0400 | SHIM T0.9 |

| 23/1. | [0] | 134139-0500 | SHIM T0.4 |

| 23/1. | [0] | 134139-0600 | SHIM T0.15 |

| 23/1. | [0] | 134139-2300 | SHIM T1.5 |

| 24. | [16] | 134132-0300 | PLAIN WASHER D20&11T2.5 |

| 26. | [16] | 013021-0040 | UNION NUT M10P1.5H8 |

| 30. | [2] | 134001-0000 | BUSHING |

| 30. | [2] | 134001-0000 | BUSHING |

| 32. | [1] | 134258-0000 | CONTROL RACK |

| 33. | [1] | 024030-2030 | BEARING PIN |

| 34. | [1] | 134222-0000 | BUSHING |

| 41. | [8] | 134241-0021 | CONTROL SLEEVE |

| 43. | [8] | 134216-0000 | SLOTTED WASHER |

| 44. | [8] | 134215-0300 | COMPRESSION SPRING |

| 45. | [8] | 134217-0500 | SLOTTED WASHER |

| 47. | [8] | 134200-0020 | TAPPET |

| 47/2. | [1] | 134204-0000 | ROLLER |

| 47/3. | [1] | 134205-0000 | BUSHING |

| 47/4. | [1] | 134203-0000 | BEARING PIN |

| 47/5. | [1] | 131206-0500 | SLIDER |

| 59. | [1] | 016650-2230 | BEARING PLATE |

| 64/1. | [0] | 134303-0000 | SHIM D59.8&43T1.2 |

| 64/1. | [0] | 134303-0100 | SHIM D59.8&43T1.5 |

| 64/1. | [0] | 134303-0200 | SHIM D59.8&43T1.8 |

| 64/1. | [0] | 134303-0300 | SHIM D59.8&43T2.0 |

| 64/1. | [0] | 134303-0400 | SHIM D59.8&43T0.6 |

| 67. | [4] | 029010-6810 | BLEEDER SCREW |

| 71. | [1] | 134381-0700 | CAMSHAFT |

| 74. | [1] | 134306-0000 | BEARING SHELL |

| 75. | [2] | 020106-2040 | BLEEDER SCREW M6P1L20 |

| 79. | [1] | 016650-2230 | BEARING PLATE |

| 80. | [1] | 134316-0100 | COVER |

| 81. | [1] | 026712-5010 | PACKING RING |

| 82/1. | [0] | 134314-0000 | SHIM T0.1 |

| 82/1. | [0] | 134314-0100 | SHIM T0.12 |

| 82/1. | [0] | 134314-0200 | SHIM T0.14 |

| 82/1. | [0] | 134314-0300 | SHIM T0.16 |

| 82/1. | [0] | 134314-0400 | SHIM T0.18 |

| 82/1. | [0] | 134314-0500 | SHIM T0.3 |

| 82/1. | [0] | 134314-0600 | SHIM T0.5 |

| 83. | [1] | 029635-5010 | O-RING |

| 85. | [1] | 134043-0700 | COVER |

| 86. | [1] | 134042-1500 | GASKET |

| 87. | [14] | 012206-1640 | FLAT-HEAD SCREW M6P1L16 |

| 88. | [1] | 134045-0100 | CAPSULE |

| 89. | [1] | 026524-2940 | GASKET D28.9&24.3T2 |

| 92. | [3] | 014110-6440 | LOCKING WASHER |

| 93. | [3] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 131041-0800 | GASKET |

| 96. | [8] | 134047-0000 | CAPSULE |

| 98. | [1] | 025805-1910 | WOODRUFF KEY |

| 111. | [1] | 134416-0000 | COVER |

| 112. | [2] | 014530-6540 | TAB WASHER |

| 113. | [2] | 021306-3010 | FLAT-HEAD SCREW |

| 118. | [1] | 134496-1200 | POINTER |

| 119. | [2] | 020006-1640 | BLEEDER SCREW M6P1L16 4T |

| 120/1. | [0] | 029310-6110 | SHIM D13.5&6.2T0.10 |

| 120/1. | [0] | 029310-6120 | SHIM D13.5&6.2T0.20 |

| 120/1. | [0] | 029310-6130 | SHIM D13.5&6.2T0.50 |

| 120/1. | [0] | 029310-6140 | SHIM D13.5&6.2T1.00 |

| 120/1. | [0] | 029310-6150 | SHIM D13.5&6.2T2.00 |

| 120/1. | [0] | 029310-6160 | SHIM D13.5&6.2T3.50 |

| 120/1. | [0] | 029310-6170 | SHIM D13.5&6.2T0.25 |

| 120/1. | [0] | 029310-6180 | SHIM D13.5&6.2T0.15 |

| 120/1. | [0] | 029310-6190 | SHIM D13.5&6.2T0.30 |

| 137. | [1] | 029731-4680 | EYE BOLT |

| 138. | [2] | 029331-4230 | GASKET |

| 147. | [1] | 029731-0120 | EYE BOLT |

| 148. | [2] | 026510-1440 | GASKET D13.9&10.2T1 |

| 157. | [1] | 029731-4680 | EYE BOLT |

| 158. | [2] | 026514-1840 | GASKET D17.9&14.2T1 |

| 167. | [1] | 132424-0620 | OVER FLOW VALVE |

| 168. | [2] | 026514-1840 | GASKET D17.9&14.2T1 |

Include in #1:

106871-0141

as FUEL INJECTION PUMP

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been some isolated instances of issues with the Diesel Particulate Filter (DPF) on certain C3.4B engines.Solution

Caterpillar is aware of this problem. Follow the procedure that is detailed below.

Table 1

Required Tools

Tool Part Number Part Description Qty

A 233-7191 Hose Cleaner Gp 1

Obtain a fuel sample from the engine.

Obtain a lubricating oil sample from the engine.

Attach a copy of the full service history of the engine to the Service Information Systems (SIMSi) report. Include the change history of the following components:

Engine oil

Engine oil filter

Engine fuel filter

Crankcase breather filter

Ensure that the breather element is clean and free from wear or damage. Replace the breather element. Refer to Operation and Maintenance Manual, Engine Crankcase Breather Element - Replace for the correct procedure. Ensure that the inlet hose is clean and free from restriction. If the inlet hose requires replacing, refer to Disassembly and Assembly, Crankcase Breather - Install for the correct procedure.

Determine the service hours of the engine air cleaner element. Ensure that the engine air cleaner element is clean and free from wear, damage, or restriction. If necessary, replace the engine air cleaner element. Refer to Operation and Maintenance Manual, Engine Air Cleaner Element (Single Element) - Inspect/Clean/Replace for the correct procedure. Ensure that the hose assemblies are clean and free from restriction and dust.

Inspect the inlet and outlet hoses of the turbocharger for the presence of excessive lubricating oil. If necessary, take photographs inside both inlet and outlet hoses. If necessary, take photographs inside the compressor housing for the inlet and outlet. If excessive lubricating oil is found, replace the turbocharger. Refer to Disassembly and Assembly, Turbocharger

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been some isolated instances of issues with the Diesel Particulate Filter (DPF) on certain C3.4B engines.Solution

Caterpillar is aware of this problem. Follow the procedure that is detailed below.

Table 1

Required Tools

Tool Part Number Part Description Qty

A 233-7191 Hose Cleaner Gp 1

Obtain a fuel sample from the engine.

Obtain a lubricating oil sample from the engine.

Attach a copy of the full service history of the engine to the Service Information Systems (SIMSi) report. Include the change history of the following components:

Engine oil

Engine oil filter

Engine fuel filter

Crankcase breather filter

Ensure that the breather element is clean and free from wear or damage. Replace the breather element. Refer to Operation and Maintenance Manual, Engine Crankcase Breather Element - Replace for the correct procedure. Ensure that the inlet hose is clean and free from restriction. If the inlet hose requires replacing, refer to Disassembly and Assembly, Crankcase Breather - Install for the correct procedure.

Determine the service hours of the engine air cleaner element. Ensure that the engine air cleaner element is clean and free from wear, damage, or restriction. If necessary, replace the engine air cleaner element. Refer to Operation and Maintenance Manual, Engine Air Cleaner Element (Single Element) - Inspect/Clean/Replace for the correct procedure. Ensure that the hose assemblies are clean and free from restriction and dust.

Inspect the inlet and outlet hoses of the turbocharger for the presence of excessive lubricating oil. If necessary, take photographs inside both inlet and outlet hoses. If necessary, take photographs inside the compressor housing for the inlet and outlet. If excessive lubricating oil is found, replace the turbocharger. Refer to Disassembly and Assembly, Turbocharger