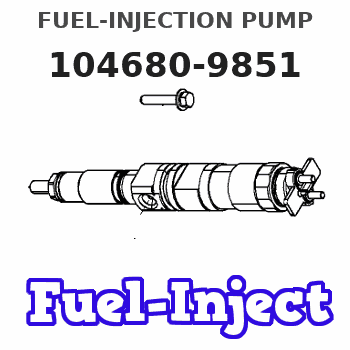

Information fuel-injection pump

BOSCH

9 461 628 121

9461628121

ZEXEL

104680-9851

1046809851

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump Compatible For NISSAN TD27 104680-9851 104780-9180 1046809851 1047809180 Engine Replacement Parts

Xqscvqwfa Part Number:104680-9851 104780-9180 || Easy Installation:Designed for hassle-free replacement with no modifications required. || Enhanced Durability:Robust construction with high-grade materials for long-lasting reliability. || Improved Fuel Efficiency:Maintains consistent fuel pressure for better combustion and reduced emissions. || Premium Quality:Precision-engineered for optimal fuel pressure and flow, ensuring smooth engine performance.

Xqscvqwfa Part Number:104680-9851 104780-9180 || Easy Installation:Designed for hassle-free replacement with no modifications required. || Enhanced Durability:Robust construction with high-grade materials for long-lasting reliability. || Improved Fuel Efficiency:Maintains consistent fuel pressure for better combustion and reduced emissions. || Premium Quality:Precision-engineered for optimal fuel pressure and flow, ensuring smooth engine performance.

Fuel Injection Pump Compatible For NISSAN TD27 104680-9851 104780-9180 1046809851 1047809180 Engine Replacement Parts

SDETASOQ Precise control: precise fuel injection, optimized combustion efficiency, reduced fuel consumption, and improved engine power output || Long lifespan and low maintenance: using high-strength wear-resistant alloy materials and corrosion-resistant coatings to reduce maintenance costs and downtime || Stable operation under all operating conditions: tested in extreme environments, continuously stable, and adaptable to various complex road and climate conditions || Silent and efficient operation: Adopting a noise reduction structure, it can maintain quietness even during high-speed operation, without interfering with the driving experience || Original Fuel Injection Pump Compatible For NISSAN TD27 104680-9851 104780-9180 1046809851 1047809180 Engine Replacement Parts

SDETASOQ Precise control: precise fuel injection, optimized combustion efficiency, reduced fuel consumption, and improved engine power output || Long lifespan and low maintenance: using high-strength wear-resistant alloy materials and corrosion-resistant coatings to reduce maintenance costs and downtime || Stable operation under all operating conditions: tested in extreme environments, continuously stable, and adaptable to various complex road and climate conditions || Silent and efficient operation: Adopting a noise reduction structure, it can maintain quietness even during high-speed operation, without interfering with the driving experience || Original Fuel Injection Pump Compatible For NISSAN TD27 104680-9851 104780-9180 1046809851 1047809180 Engine Replacement Parts

Original Fuel Injection Pump Compatible For NISSAN TD27 104680-9851 104780-9180 1046809851 1047809180 Engine Replacement Parts

ASGIHVAC Material: made of high-quality materials, with the characteristics of corrosion resistance and high strength. || Quality: manufactured according to strict quality control standards, not easy to damage, long service life. || Performance: stable performance, high reliability and good performance, specially designed for silent operation. || Appearance: the appearance is novel and beautiful, and the installation is convenient. || Original Fuel Injection Pump Compatible For NISSAN TD27 104680-9851 104780-9180 1046809851 1047809180 Engine Replacement Parts

ASGIHVAC Material: made of high-quality materials, with the characteristics of corrosion resistance and high strength. || Quality: manufactured according to strict quality control standards, not easy to damage, long service life. || Performance: stable performance, high reliability and good performance, specially designed for silent operation. || Appearance: the appearance is novel and beautiful, and the installation is convenient. || Original Fuel Injection Pump Compatible For NISSAN TD27 104680-9851 104780-9180 1046809851 1047809180 Engine Replacement Parts

You can express buy:

USD 406.7

14-06-2025

14-06-2025

Diesel Fuel Injection Pump 104680-9851 10F1150RNP2171 104780-9180 for Forklift Truck Pickup TD27 Engine

Images:

USD 406.7

[19-May-2025]

USD 411.32

[13-May-2025]

USD 393.14

[13-May-2025]

USD 450

[13-May-2025]

Include in #2:

104780-9851

as FUEL INJECTION PUMP

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Illustration 16 g00628694

(9) Fuel injector clamp. (10) Bolt. (11) O-ring seal.

Place the clamp (9) in the proper position. Temporarily place the jumper tube in position in order to ensure alignment of the bolt holes. Adjust the orientation of the injector until the alignment is satisfactory. Torque the bolt (10) to the following torque. Remove the jumper tube.Torque for bolt ... 47 9 N m (35 7 lb ft)

Illustration 17 g00628691

(12) O-ring seals in the injector jumper tube. (13) O-ring seals in the base of the rocker arm.

Replace the used O-ring seal (11), and the O-ring seals (12) and (13) in the jumper tube and in the rocker arm.

Illustration 18 g00628693

(14) Jumper tube. (15) Bolts. (16) Adapter. (17) Socket head screws.

Place the jumper tube (14) and the adapter (16) into position.

If the adapter was previously installed on the injector, loosen the socket head screws. Failure to loosen the socket head screws before continuing with Step 8 can result in injector failure.

Install the socket head screws (17) and the four bolts (15) finger tight.Note: The mating surfaces should be brought into complete contact and into alignment before the final torque procedure is started.

Failure to follow any of the procedures in this instruction may result in injector damage or malfunction, and possible major engine damage.

Torque Procedure

Illustration 19 g00338156

(1) Socket head screws.

Illustration 20 g00338157

(2) Two horizontal bolts. (3) Two vertical bolts.

Tighten the socket head screws (1), the two horizontal bolts (2), and the two vertical bolts (3) finger tight.

Tighten the socket head screws (1) to an initial torque of 1 .2 N m (9 2 lb in).

Tighten the horizontal bolts (2) to an initial torque of 5 3 N m (44 27 lb in).

Tighten the vertical bolts (3) to an initial torque of 5 3 N m (44 27 lb in).

Tighten the socket head screws (1) to a final torque of 12 3 N m (9 2 lb ft).

Tighten the horizontal bolts (2) to a final torque of 47 9 N m (35 7 lb ft).

Tighten the vertical bolts (3) to a final torque of 47 9 N m (35 7 lb ft).

Repeat Step 1 through Step 7 for the remainder of the injectors.

Check the fuel system for leaks by cranking the engine with the disabled injection. Then check the hydraulic pressure. Compare the pressure to the desired pressure.Cranking Without Injecting

Cranking the engine with the disabled injection may be performed by one of the following methods:

Disconnect the injector harness of the cylinders which have been reinstalled. Allow the engine to idle. Visually inspect the injector's components for high pressure oil leaks.

Activate the system "Crank Without Inject" if the option is available. On Track-Type Tractors, a "Crank Without Inject" plug can be assembled in the engine harness. On Off-Highway Trucks, the "Ground Level Shutdown" can be activated if the option is available.

When you are using the CAT ET or the ECAP, the injection may be disabled by interactive diagnostics. The engine can be left