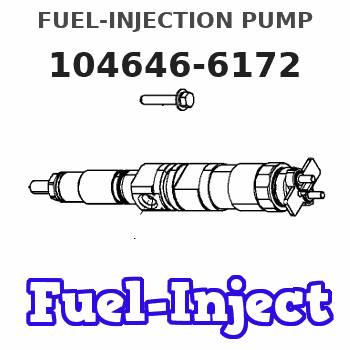

Information fuel-injection pump

BOSCH

9 461 617 805

9461617805

ZEXEL

104646-6172

1046466172

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

WBFRYEE Diesel Fuel Injection Pump 104646-6172 VE4/11F1900LNP1687

WBFRYEE The fuel injection pump needs to be maintained, and the filter screen, sealing ring and other vulnerable parts should be replaced regularly to ensure normal operation. || The fuel injection pump needs to cooperate with the engine control unit (ECU) to achieve accurate control and adjustment. || The working pressure of pressure pump is usually hundreds or thousands of bars, the specific value depends on the engine model and design requirements. || The injector will control the injection according to the engine load || The working state of fuel injection pump will directly affect the power and fuel economy of the engine.

WBFRYEE The fuel injection pump needs to be maintained, and the filter screen, sealing ring and other vulnerable parts should be replaced regularly to ensure normal operation. || The fuel injection pump needs to cooperate with the engine control unit (ECU) to achieve accurate control and adjustment. || The working pressure of pressure pump is usually hundreds or thousands of bars, the specific value depends on the engine model and design requirements. || The injector will control the injection according to the engine load || The working state of fuel injection pump will directly affect the power and fuel economy of the engine.

Diesel VE Fuel Injection Pump 104646-6172 VE4/11F1900LNP1687

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel VE Fuel Injection Pump 104646-6172 VE4/11F1900LNP1687

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel VE Fuel Injection Pump 104646-6172 VE4/11F1900LNP1687

OEM 104646-6172 VE4/11F1900LNP1687 Oil Pump Fuel Injection Pump Compatible With Diesel Engine

LIYOGWUL Wide applicability: The oil pump is suitable for various types of gasoline engines, such as engines, diesel engines, etc || Easy to install: Mechanical oil pump compact structure, reduce installation time and easy maintenance, reduce the cost of use || Enhanced driving experience: Engine lubrication pumps improve driving comfort and experience with low noise and smooth operation || Heat dissipation function: self-priming oil pump helps the engine heat dissipation through oil circulation, reduce the working temperature and better heat dissipation || OEM 104646-6172 VE4/11F1900LNP1687 Oil Pump Fuel Injection Pump Compatible With Diesel Engine

LIYOGWUL Wide applicability: The oil pump is suitable for various types of gasoline engines, such as engines, diesel engines, etc || Easy to install: Mechanical oil pump compact structure, reduce installation time and easy maintenance, reduce the cost of use || Enhanced driving experience: Engine lubrication pumps improve driving comfort and experience with low noise and smooth operation || Heat dissipation function: self-priming oil pump helps the engine heat dissipation through oil circulation, reduce the working temperature and better heat dissipation || OEM 104646-6172 VE4/11F1900LNP1687 Oil Pump Fuel Injection Pump Compatible With Diesel Engine

Include in #2:

104746-6172

as FUEL INJECTION PUMP

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

3406B and 3406C Non-Peec Engines

Steps 4 through 7 do not apply to PEEC engines.

Illustration 16. Install Lever Assembly

(1) 6N-3646 Lever. (2) 5P-0537 Washer. (3) 6V-8918 Bolt. (4) 9M-3858 Rack Preload Spring. (5) 1B-7182 Bolt.4. Install lever (1) with washer (2) and bolt (3).5. Install bolt (5) into hole as shown.6. Hook spring (4) between bolt (5) and lever (1).

Illustration 17. Install Rack Positioning Assembly

(1) 9U-5296 Rack Assembly. (2) Original cover mounting bolts or 4F-7957 Bolt.7. Install rack positioning assembly (1) with bolts (2). Use rack positioning assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.3406 Peec Engines

Steps 8 and 9 do not apply to Non-PEEC engines.

Illustration 18. Installing testing hardware for 3406 PEEC Engines

(1) 9U-5292 Rack Preload Assembly. (2) 9U-5120 Spanner Wrench. (3) 9U-5295 Positioning Assembly.8. Remove the BTM from the injection pump and install the 9U-5292 Rack Preload Assembly (1). Make sure the pin is properly located in the slot of the servo shaft. After installing the rack preload assembly, finger tighten the bolts.9. Remove the shut-off solenoid with a 9U-5120 Spanner Wrench (2) and install 9U-5295 Positioning Assembly (3). Use rack preload assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.Connect Hoses and Lines

Illustration 19. Connect Lube Oil Supply and Drain Hose

(1) 7G-7105 Hose. (2) 5P-6661 Fitting. (3) 9U-7709 Oil Drain Tube and two 5D-1026 Hose Clamps.

Illustration 20. Connect Fuel Supply and Return Lines

(4) 030-7947 Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (5) 8T-2160 Orifice Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (6) 9U-5298 Fuel Injection Line Tube Assembly (verify fuel line part number in TMI).1. Attach one end of hose (1) to the Lube Oil Supply fitting on the test stand. Attach the other end to the 5P-6661 Fitting on the rear support.2. Connect the oil drain tube (2) to the rear support and the test stand's stand-pipe with two hose clamps. On the AVM20-12C, the drain hose can be routed to the lube oil drain pan.3. Install fitting, O-ring, and hose (4) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Supply" connection on the test stand.4. Install fitting, O-ring, and hose (5) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Return" connection on the test stand.

Hold nut on 9U-6705 Master Nozzle when tightening fuel injection line tube assemblies (6). If the nut is not held in place during tightening, the master nozzle can be damaged.

5. Install six fuel injection line tube assemblies (6).Pre-Test Checks

1. Remove the lock-out on the electrical box, if installed.2. Release the Emergency Stop button.3. Start the bench and visually check for oil leaks from covers, hoses, etc.4. Check for oil flow through the drain tube. Also, check for oil flowing out of the oil

Steps 4 through 7 do not apply to PEEC engines.

Illustration 16. Install Lever Assembly

(1) 6N-3646 Lever. (2) 5P-0537 Washer. (3) 6V-8918 Bolt. (4) 9M-3858 Rack Preload Spring. (5) 1B-7182 Bolt.4. Install lever (1) with washer (2) and bolt (3).5. Install bolt (5) into hole as shown.6. Hook spring (4) between bolt (5) and lever (1).

Illustration 17. Install Rack Positioning Assembly

(1) 9U-5296 Rack Assembly. (2) Original cover mounting bolts or 4F-7957 Bolt.7. Install rack positioning assembly (1) with bolts (2). Use rack positioning assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.3406 Peec Engines

Steps 8 and 9 do not apply to Non-PEEC engines.

Illustration 18. Installing testing hardware for 3406 PEEC Engines

(1) 9U-5292 Rack Preload Assembly. (2) 9U-5120 Spanner Wrench. (3) 9U-5295 Positioning Assembly.8. Remove the BTM from the injection pump and install the 9U-5292 Rack Preload Assembly (1). Make sure the pin is properly located in the slot of the servo shaft. After installing the rack preload assembly, finger tighten the bolts.9. Remove the shut-off solenoid with a 9U-5120 Spanner Wrench (2) and install 9U-5295 Positioning Assembly (3). Use rack preload assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.Connect Hoses and Lines

Illustration 19. Connect Lube Oil Supply and Drain Hose

(1) 7G-7105 Hose. (2) 5P-6661 Fitting. (3) 9U-7709 Oil Drain Tube and two 5D-1026 Hose Clamps.

Illustration 20. Connect Fuel Supply and Return Lines

(4) 030-7947 Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (5) 8T-2160 Orifice Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (6) 9U-5298 Fuel Injection Line Tube Assembly (verify fuel line part number in TMI).1. Attach one end of hose (1) to the Lube Oil Supply fitting on the test stand. Attach the other end to the 5P-6661 Fitting on the rear support.2. Connect the oil drain tube (2) to the rear support and the test stand's stand-pipe with two hose clamps. On the AVM20-12C, the drain hose can be routed to the lube oil drain pan.3. Install fitting, O-ring, and hose (4) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Supply" connection on the test stand.4. Install fitting, O-ring, and hose (5) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Return" connection on the test stand.

Hold nut on 9U-6705 Master Nozzle when tightening fuel injection line tube assemblies (6). If the nut is not held in place during tightening, the master nozzle can be damaged.

5. Install six fuel injection line tube assemblies (6).Pre-Test Checks

1. Remove the lock-out on the electrical box, if installed.2. Release the Emergency Stop button.3. Start the bench and visually check for oil leaks from covers, hoses, etc.4. Check for oil flow through the drain tube. Also, check for oil flowing out of the oil