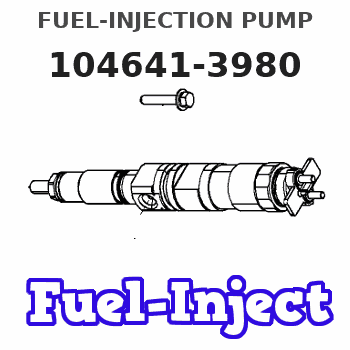

Information fuel-injection pump

BOSCH

9 461 627 084

9461627084

ZEXEL

104641-3980

1046413980

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection VE Pump VE4/11F1250RNP2487 104641-3980 32C65-00230 32C6500230,compatible For MITSUBISHI S4Q2 Engine

NZMSMS Precision - Engineered Compatibility: The Fuel Injection VE Pump VE4/11F1250RNP2487, 104641-3980, 32C65-00230, and 32C6500230 are meticulously designed to be a perfect,compatible for Mitsubishi S4Q2 Engine. Every dimension, connection interface, and internal specification is crafted to match the original fuel injection system requirements of this engine precisely. No need for complex modifications—simply install the pump, and it integrates seamlessly, ensuring immediate and consistent fuel || High - Precision Fuel Injection: Engineered with cutting - edge technology, these VE pumps offer unparalleled precision in fuel delivery. Advanced sensors continuously monitor key engine parameters like speed, load, and temperature in real - time. Paired with intelligent control systems, they make instant and accurate adjustments to the fuel injection volume and timing, ensuring,compatible for Mitsubishi S4Q2 Engine receives the exact amount of fuel it needs at every moment. This precision not || Rugged and Durable Construction: Built to withstand the demanding conditions of engine operation, the Fuel Injection VE Pump series is constructed from top - grade, heavy - duty materials. The pump housing is made from a robust, corrosion - resistant alloy that can endure exposure to high heat, vibrations, and fuel contaminants within the engine environment. Its internal components, including injection nozzles, plungers, and valves, are crafted from premium - quality materials designed to || Enhanced Fuel Efficiency: In an era where fuel costs are a major concern, our Fuel Injection VE Pumps,compatible for Mitsubishi S4Q2 Engine provide an effective solution to optimize fuel consumption. By delivering a precise and consistent fuel supply, they enable the engine to achieve a more efficient fuel - air combustion. The intelligent control systems prevent over - injection, ensuring that every drop of fuel is utilized to its maximum potential. || Reliable Operation in All Conditions: No matter the operating environment or conditions, these VE pumps perform consistently. Engineered to function reliably in extreme temperatures, from the freezing cold of winter to the scorching heat of summer, they maintain stable operation. The built - in pressure regulation and monitoring features work in harmony to keep the fuel injection pressure within the optimal range, preventing fluctuations that could disrupt engine performance. Additionally, they

NZMSMS Precision - Engineered Compatibility: The Fuel Injection VE Pump VE4/11F1250RNP2487, 104641-3980, 32C65-00230, and 32C6500230 are meticulously designed to be a perfect,compatible for Mitsubishi S4Q2 Engine. Every dimension, connection interface, and internal specification is crafted to match the original fuel injection system requirements of this engine precisely. No need for complex modifications—simply install the pump, and it integrates seamlessly, ensuring immediate and consistent fuel || High - Precision Fuel Injection: Engineered with cutting - edge technology, these VE pumps offer unparalleled precision in fuel delivery. Advanced sensors continuously monitor key engine parameters like speed, load, and temperature in real - time. Paired with intelligent control systems, they make instant and accurate adjustments to the fuel injection volume and timing, ensuring,compatible for Mitsubishi S4Q2 Engine receives the exact amount of fuel it needs at every moment. This precision not || Rugged and Durable Construction: Built to withstand the demanding conditions of engine operation, the Fuel Injection VE Pump series is constructed from top - grade, heavy - duty materials. The pump housing is made from a robust, corrosion - resistant alloy that can endure exposure to high heat, vibrations, and fuel contaminants within the engine environment. Its internal components, including injection nozzles, plungers, and valves, are crafted from premium - quality materials designed to || Enhanced Fuel Efficiency: In an era where fuel costs are a major concern, our Fuel Injection VE Pumps,compatible for Mitsubishi S4Q2 Engine provide an effective solution to optimize fuel consumption. By delivering a precise and consistent fuel supply, they enable the engine to achieve a more efficient fuel - air combustion. The intelligent control systems prevent over - injection, ensuring that every drop of fuel is utilized to its maximum potential. || Reliable Operation in All Conditions: No matter the operating environment or conditions, these VE pumps perform consistently. Engineered to function reliably in extreme temperatures, from the freezing cold of winter to the scorching heat of summer, they maintain stable operation. The built - in pressure regulation and monitoring features work in harmony to keep the fuel injection pressure within the optimal range, preventing fluctuations that could disrupt engine performance. Additionally, they

Compatible For ISUZU 4jg2 Diesel Engine Fuel Pump 104641-3980 Injection Pump NP-VE4/11F1250RNP2487

NZMSMS Precision - Engineered Compatibility: The Fuel Pump 104641-3980 and Injection Pump NP-VE4/11F1250RNP2487 are meticulously designed to be a perfect,compatible for ISUZU 4jg2 Diesel Engine. Every dimension, connection interface, and internal specification is crafted to match the original fuel injection system requirements of this engine precisely. No need for complex modifications—simply install the pump, and it integrates seamlessly, ensuring immediate and consistent fuel injection for optimal || High - Precision Fuel Injection: Engineered with advanced technology, these pumps offer unparalleled precision in fuel delivery,compatible for ISUZU 4jg2 Diesel Engine. Advanced sensors continuously monitor key engine parameters like speed, load, and temperature in real - time. Paired with intelligent control systems, they make instant and accurate adjustments to the fuel injection volume and timing, ensuring that the engine receives the exact amount of fuel it needs at every moment. This || Rugged and Durable Construction: Built to withstand the demanding conditions of diesel engine operation, the Fuel Pump 104641-3980 and Injection Pump NP-VE4/11F1250RNP2487 are constructed from top - grade, heavy - duty materials. The pump housing is made from a robust, corrosion - resistant alloy that can endure exposure to high heat, vibrations, and fuel contaminants within the engine environment. Its internal components, including injection nozzles, plungers, and valves, are crafted from || Enhanced Fuel Efficiency: In an era where fuel costs are a major concern, our fuel pumps,compatible for ISUZU 4jg2 Diesel Engine provide an effective solution to optimize fuel consumption. By delivering a precise and consistent fuel supply, they enable the engine to achieve a more efficient fuel - air combustion. The intelligent control systems prevent over - injection, ensuring that every drop of fuel is utilized to its maximum potential. || Reliable Operation in All Conditions: No matter the operating environment or conditions, these pumps perform consistently,compatible for ISUZU 4jg2 Diesel Engine. Engineered to function reliably in extreme temperatures, from the freezing cold of winter to the scorching heat of summer, they maintain stable operation. The built - in pressure regulation and monitoring features work in harmony to keep the fuel injection pressure within the optimal range, preventing fluctuations that could disrupt

NZMSMS Precision - Engineered Compatibility: The Fuel Pump 104641-3980 and Injection Pump NP-VE4/11F1250RNP2487 are meticulously designed to be a perfect,compatible for ISUZU 4jg2 Diesel Engine. Every dimension, connection interface, and internal specification is crafted to match the original fuel injection system requirements of this engine precisely. No need for complex modifications—simply install the pump, and it integrates seamlessly, ensuring immediate and consistent fuel injection for optimal || High - Precision Fuel Injection: Engineered with advanced technology, these pumps offer unparalleled precision in fuel delivery,compatible for ISUZU 4jg2 Diesel Engine. Advanced sensors continuously monitor key engine parameters like speed, load, and temperature in real - time. Paired with intelligent control systems, they make instant and accurate adjustments to the fuel injection volume and timing, ensuring that the engine receives the exact amount of fuel it needs at every moment. This || Rugged and Durable Construction: Built to withstand the demanding conditions of diesel engine operation, the Fuel Pump 104641-3980 and Injection Pump NP-VE4/11F1250RNP2487 are constructed from top - grade, heavy - duty materials. The pump housing is made from a robust, corrosion - resistant alloy that can endure exposure to high heat, vibrations, and fuel contaminants within the engine environment. Its internal components, including injection nozzles, plungers, and valves, are crafted from || Enhanced Fuel Efficiency: In an era where fuel costs are a major concern, our fuel pumps,compatible for ISUZU 4jg2 Diesel Engine provide an effective solution to optimize fuel consumption. By delivering a precise and consistent fuel supply, they enable the engine to achieve a more efficient fuel - air combustion. The intelligent control systems prevent over - injection, ensuring that every drop of fuel is utilized to its maximum potential. || Reliable Operation in All Conditions: No matter the operating environment or conditions, these pumps perform consistently,compatible for ISUZU 4jg2 Diesel Engine. Engineered to function reliably in extreme temperatures, from the freezing cold of winter to the scorching heat of summer, they maintain stable operation. The built - in pressure regulation and monitoring features work in harmony to keep the fuel injection pressure within the optimal range, preventing fluctuations that could disrupt

WBFRYEE Diesel Fuel Injection Pump 104641-3980 NP-VE4/11F1250RNP2487 Compatible with Isuzu

WBFRYEE Firm structure and stable || Reliability, firmness and durability || Ensure the stable operation of the engine. || Provide a stable fuel supply to ensure the normal operation of the vehicle. || Fuel pump metering unit is an important part of engine electronic gasoline injection system.

WBFRYEE Firm structure and stable || Reliability, firmness and durability || Ensure the stable operation of the engine. || Provide a stable fuel supply to ensure the normal operation of the vehicle. || Fuel pump metering unit is an important part of engine electronic gasoline injection system.

You can express buy:

USD 388

13-05-2025

13-05-2025

Fuel Injection VE Pump VE4/11F1250RNP2487 104641-3980 32C65-00230 32C6500230 for MITSUBISHI S4Q2 Engine

USD 388.94

13-05-2025

13-05-2025

104641-3980 NP-VE4/11F1250RNP2487 NEW Automotive Parts Automotive Diesel Engine Fuel Injection Pump VE Fuel Pump Assembly

Images:

USD 433.07

[19-May-2025]

USD 419.1

[19-May-2025]

USD 530.86

[26-May-2025]

Include in #2:

104741-3980

as FUEL INJECTION PUMP

Cross reference number

Zexel num

Bosch num

Firm num

Name

104641-3980

FUEL-INJECTION PUMP

Q 11CJ FUEL INJECTION PUMP VE4 VE

Q 11CJ FUEL INJECTION PUMP VE4 VE

Information:

3114 ATAAC Engine Model Views

Oil Filter (1), Fan Pulley & Bearing Assembly (2), Thermostat Housing (3), Alternator (4), Turbocharger (5), Electric Starting Motor (6), Crankshaft Pulley (7), Water Pump (8), Oil Level Gage (Dipstick) (9), Oil Drain Plug (10), Fuel Transfer Pump and Governor (11), Air Compressor (12), Oil Filler (13), Fuel Filter (14), Air Cleaner with Restriction Gauge (15), Lift Eye (16), Fuel Priming Pump (17), Crankcase Breather (18) and Power Steering Pump (19).3116 ATAAC Engine Model Views

LEFT SIDE VIEW

Fan Pulley & Bearing Assembly (1), Thermostat Housing (2), Crankshaft Vibration Damper & Pulley (3116 ONLY) (3), Oil Level Gage (Dipstick) (4), Oil Drain Plug (5), Fuel Transfer Pump and Governor (6), Air Compressor (7), Oil Filler (8), Fuel Filter (9), Lift Eye (10), Fuel Priming Pump (11), Crankcase Breather (12) and Power Steering Pump (13), Fuel Filter Bleed Screw (14).Engine Information

The engines described in this Manual are the 3114 and 3116 ATAAC Diesel Truck engines designed primarily for on-highway medium duty applications.3114 Engine

The Caterpillar 3114 Truck (Vehicular) Engine has a 4.4 liter (269 inch3) displacement, with 105 mm (4.13 inch) bore and 127 mm (5.0 inch) stroke. The engine is a four stroke cycle, in-line 4 cylinder with direct injection. 3116 Engine

The Caterpillar 3116 Truck (Vehicular) Engine has a 6.6 liter (403 inch3) displacement, with 105 mm (4.13 inch) bore and 127 mm (5.0 inch) stroke. The engine is a four stroke cycle, in-line 6 cylinder with direct injection. All Engines

3114 & 3116 Cylinder and Valve Location Rated speed for the Truck (Vehicular) Engine, turbocharged with Air-to-Air Aftercooling System (ATAAC), equipped with a mechanical governor and high pressure injection fuel system is 2600 rpm. Refer to the Information Plate or Caterpillar for information regarding your engine.The cooling system consists of a belt driven centrifugal pump, with a thermostat which regulates engine coolant temperature, electric fan clutch, an oil cooler and a radiator incorporating a shunt system.The engine lubricating oil (both cooled and filtered) is supplied by a gear-type pump and bypass valves provide unrestricted flow of oil to engine parts when oil viscosity is high, or if the oil cooler or filter elements become plugged.To obtain maximum efficiency and lowest cost to operate and own your Caterpillar engine, use only recommended fuels and lubricants and follow the maintenance recommendations in the Maintenance Schedule which can be found in the Maintenance Section of this Manual.Serial Number Plate and Information Plate Locations

Engine Identification

Caterpillar engines are identified with Serial Numbers, Performance Specification Numbers (fuel system settings) and Arrangement Numbers. In some cases Modification Numbers are also used. These numbers are shown on the Serial Number Plate (1) mounted on the engine.Caterpillar needs all of these numbers to determine which components were included on the engine when it was assembled at the factory. This permits accurate identification of replacement part numbers.Serial Number Plate

There are two possible locations for the Serial Number Plate (1).Some engines have the plate on the left side of the engine and some engines will have the

Oil Filter (1), Fan Pulley & Bearing Assembly (2), Thermostat Housing (3), Alternator (4), Turbocharger (5), Electric Starting Motor (6), Crankshaft Pulley (7), Water Pump (8), Oil Level Gage (Dipstick) (9), Oil Drain Plug (10), Fuel Transfer Pump and Governor (11), Air Compressor (12), Oil Filler (13), Fuel Filter (14), Air Cleaner with Restriction Gauge (15), Lift Eye (16), Fuel Priming Pump (17), Crankcase Breather (18) and Power Steering Pump (19).3116 ATAAC Engine Model Views

LEFT SIDE VIEW

Fan Pulley & Bearing Assembly (1), Thermostat Housing (2), Crankshaft Vibration Damper & Pulley (3116 ONLY) (3), Oil Level Gage (Dipstick) (4), Oil Drain Plug (5), Fuel Transfer Pump and Governor (6), Air Compressor (7), Oil Filler (8), Fuel Filter (9), Lift Eye (10), Fuel Priming Pump (11), Crankcase Breather (12) and Power Steering Pump (13), Fuel Filter Bleed Screw (14).Engine Information

The engines described in this Manual are the 3114 and 3116 ATAAC Diesel Truck engines designed primarily for on-highway medium duty applications.3114 Engine

The Caterpillar 3114 Truck (Vehicular) Engine has a 4.4 liter (269 inch3) displacement, with 105 mm (4.13 inch) bore and 127 mm (5.0 inch) stroke. The engine is a four stroke cycle, in-line 4 cylinder with direct injection. 3116 Engine

The Caterpillar 3116 Truck (Vehicular) Engine has a 6.6 liter (403 inch3) displacement, with 105 mm (4.13 inch) bore and 127 mm (5.0 inch) stroke. The engine is a four stroke cycle, in-line 6 cylinder with direct injection. All Engines

3114 & 3116 Cylinder and Valve Location Rated speed for the Truck (Vehicular) Engine, turbocharged with Air-to-Air Aftercooling System (ATAAC), equipped with a mechanical governor and high pressure injection fuel system is 2600 rpm. Refer to the Information Plate or Caterpillar for information regarding your engine.The cooling system consists of a belt driven centrifugal pump, with a thermostat which regulates engine coolant temperature, electric fan clutch, an oil cooler and a radiator incorporating a shunt system.The engine lubricating oil (both cooled and filtered) is supplied by a gear-type pump and bypass valves provide unrestricted flow of oil to engine parts when oil viscosity is high, or if the oil cooler or filter elements become plugged.To obtain maximum efficiency and lowest cost to operate and own your Caterpillar engine, use only recommended fuels and lubricants and follow the maintenance recommendations in the Maintenance Schedule which can be found in the Maintenance Section of this Manual.Serial Number Plate and Information Plate Locations

Engine Identification

Caterpillar engines are identified with Serial Numbers, Performance Specification Numbers (fuel system settings) and Arrangement Numbers. In some cases Modification Numbers are also used. These numbers are shown on the Serial Number Plate (1) mounted on the engine.Caterpillar needs all of these numbers to determine which components were included on the engine when it was assembled at the factory. This permits accurate identification of replacement part numbers.Serial Number Plate

There are two possible locations for the Serial Number Plate (1).Some engines have the plate on the left side of the engine and some engines will have the