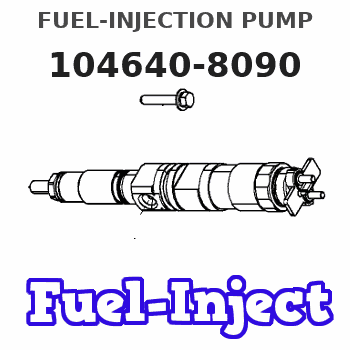

Information fuel-injection pump

BOSCH

9 461 614 313

9461614313

ZEXEL

104640-8090

1046408090

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

104640-8090 VE4/10F2100RNP849 Engine Parts Diesel Fuel Injection Pump 104640 8090

NZMSMS Precision - Engineered Compatibility: The 104640-8090 VE4/10F2100RNP849 Diesel Fuel Injection Pump is meticulously designed to seamlessly integrate with a wide range of engines. Every dimension, connection interface, and internal specification has been carefully crafted to match the original fuel injection system requirements precisely. Whether you’re a professional mechanic working on diverse engine models or an engine owner seeking to upgrade your fuel system, installation is straightforward. || Advanced Precision Fuel Injection: Equipped with state - of - the - art technology, this fuel injection pump offers unparalleled precision in fuel delivery. Advanced sensors continuously monitor key engine parameters such as speed, load, and temperature in real - time. Paired with intelligent control systems, it makes instant and accurate adjustments to the fuel injection volume and timing. This ensures that the engine receives the exact amount of fuel it needs at every moment, resulting in || Rugged and Durable Construction: Built to withstand the demanding conditions of diesel engine operation, the 104640-8090 VE4/10F2100RNP849 fuel injection pump is constructed from high - quality, heavy - duty materials. The pump housing is made from a robust, corrosion - resistant alloy that can endure exposure to high heat, vibrations, and fuel contaminants. The internal components, including injection nozzles, plungers, and valves, are crafted from premium - grade materials designed to handle || Enhanced Fuel Efficiency: In an era where fuel costs can have a major impact on your bottom line, our fuel injection pump offers an effective solution to optimize fuel consumption. By delivering a precise and consistent fuel supply, it enables the engine to achieve a more efficient fuel - air combustion. The intelligent control system prevents over - injection, ensuring that every drop of fuel is utilized effectively. In a 10,000 - hour test run, engines with our fuel injection pump saved an || Reliable Operation in All Conditions: No matter the operating environment or conditions, this fuel injection pump performs consistently. Engineered to function reliably in extreme temperatures, from the freezing cold of winter to the scorching heat of summer, it features intelligent pressure regulation and monitoring systems that maintain optimal fuel injection pressure within a tight tolerance of ± 0.3 psi. Additionally, it can handle variations in fuel quality, ensuring smooth operation even

NZMSMS Precision - Engineered Compatibility: The 104640-8090 VE4/10F2100RNP849 Diesel Fuel Injection Pump is meticulously designed to seamlessly integrate with a wide range of engines. Every dimension, connection interface, and internal specification has been carefully crafted to match the original fuel injection system requirements precisely. Whether you’re a professional mechanic working on diverse engine models or an engine owner seeking to upgrade your fuel system, installation is straightforward. || Advanced Precision Fuel Injection: Equipped with state - of - the - art technology, this fuel injection pump offers unparalleled precision in fuel delivery. Advanced sensors continuously monitor key engine parameters such as speed, load, and temperature in real - time. Paired with intelligent control systems, it makes instant and accurate adjustments to the fuel injection volume and timing. This ensures that the engine receives the exact amount of fuel it needs at every moment, resulting in || Rugged and Durable Construction: Built to withstand the demanding conditions of diesel engine operation, the 104640-8090 VE4/10F2100RNP849 fuel injection pump is constructed from high - quality, heavy - duty materials. The pump housing is made from a robust, corrosion - resistant alloy that can endure exposure to high heat, vibrations, and fuel contaminants. The internal components, including injection nozzles, plungers, and valves, are crafted from premium - grade materials designed to handle || Enhanced Fuel Efficiency: In an era where fuel costs can have a major impact on your bottom line, our fuel injection pump offers an effective solution to optimize fuel consumption. By delivering a precise and consistent fuel supply, it enables the engine to achieve a more efficient fuel - air combustion. The intelligent control system prevents over - injection, ensuring that every drop of fuel is utilized effectively. In a 10,000 - hour test run, engines with our fuel injection pump saved an || Reliable Operation in All Conditions: No matter the operating environment or conditions, this fuel injection pump performs consistently. Engineered to function reliably in extreme temperatures, from the freezing cold of winter to the scorching heat of summer, it features intelligent pressure regulation and monitoring systems that maintain optimal fuel injection pressure within a tight tolerance of ± 0.3 psi. Additionally, it can handle variations in fuel quality, ensuring smooth operation even

You can express buy:

USD 420

19-05-2025

19-05-2025

104640-8090 VE4/10F2100RNP849 Engine Parts Diesel Fuel Injection Pump 104640 8090

USD 388.94

13-05-2025

13-05-2025

104640-8090 NP-VE4/10F2100RNP849 Engine Parts Diesel Fuel Injection Pump For Engine Excavator

Images:

USD 435.72

[19-May-2025]

USD 407.92

[19-May-2025]

USD 394.66

[29-May-2025]

Include in #2:

104740-8090

as FUEL INJECTION PUMP

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Bend the lock tab and remove bolt (1).

The oil pump idler gear (3) can fall off the pump when the pump is removed. Injury can be the result. To prevent injury, always hold idler gear on the pump when the pump is removed.

2. Bend the two tabs on locks (4) on the left hand side of the engine. Remove the four bolts (2) and (5) and remove the oil pump and suction bell as a unit. Be sure the idler gear (3) is engaged with the crankshaft gear and tabs on locks (4) on bolts (5) are not next to the oil pan gasket surface when bolts (2) and (5) are tightened. Install in reverse order.End By:a. install oil pan

Perform Scheduled Oil Sampling on oil wetted compartments after performing service work to check for contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.

Disassemble Oil Pump

Start By:a. remove oil pump

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove idler gear (2). Remove the bearing from the idler gear with tooling (B).2. Remove suction bell (1) and the bolt and the washer from the oil pump drive gear. 3. Remove the drive gear from the shaft with tooling (A).4. Remove the key from the pump shaft and bolts (3). 5. Remove body (8), two gears (7), the keys and spacer (4).6. Remove two shafts (5) and the gears.7. Remove bolts (6), the cover and the pressure relief valve. 8. Remove the bearings from the oil pump body assembly and the scavenge pump body assembly with tooling (B).Assemble Oil Pump

1. Install the bearings in the scavenge pump body assembly with tooling (B) and a press as follows:a. Put bearings (9) in position on the inside of the scavenge pump body assembly with the chamfer on the bearing toward the outside of the pump body. Install the bearing until it is 1.52 mm (.060 in) below the inside machined surface of the scavenge pump body assembly. Make sure the joints in the bearings are at an angle of 30° 15° from the center line through the bores in the scavenge pump body and toward the outlet passage of the pump. The outlet passage has a cavity between the bearing bores. 2. Install the bearings in oil pump body assembly with tooling (B) and a press as follows.a. Put bearings (10) in position on the inside of the oil pump body assembly with the chamfer on the bearings toward the outside of the pump body. Install the bearings until they are even with the outside of the pump at an angle of 30° 15° from the centerline through the bearing bores and toward the outlet passage of the pump. The outlet passage has a cavity between the bearing bores.3. Check