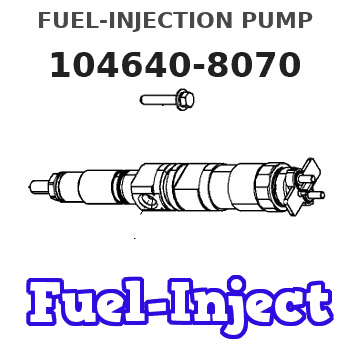

Information fuel-injection pump

BOSCH

9 461 614 311

9461614311

ZEXEL

104640-8070

1046408070

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

VE4 Fuel Injection Pump for Mitsubishi Shogun Pajero L200 2.5 TD 104640-8070 1046408070 9461614311

KoovDem Part Number: 104640-8070, 1046408070, 9461614311, VE4/10F2100RNP688 || Compatible Model: for Mitsubishi Shogun Pajero L200 2.5 TD || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

KoovDem Part Number: 104640-8070, 1046408070, 9461614311, VE4/10F2100RNP688 || Compatible Model: for Mitsubishi Shogun Pajero L200 2.5 TD || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

Original Fuel Injection Pump,Compatible For Mitsubishi Pajero L200 2.5 TD ZEXEL 104640-8070 9461614311 1046408070 Engine Replacement Parts

BDBHKM High-quality replacement for listed models fuel injection system || Compatible with ZEXEL part number 104640-8070 and OEM number 9461614311 || Designed to enhance engine performance and fuel efficiency || Durable construction ensures long-lasting reliability and optimal operation || Easy installation process, perfect for DIY enthusiasts and professional mechanics alike

BDBHKM High-quality replacement for listed models fuel injection system || Compatible with ZEXEL part number 104640-8070 and OEM number 9461614311 || Designed to enhance engine performance and fuel efficiency || Durable construction ensures long-lasting reliability and optimal operation || Easy installation process, perfect for DIY enthusiasts and professional mechanics alike

Fuel Injection Pump Engine Replacement Parts, Compatible With Mitsubishi Pajero L200 2.5 TD ZEXEL 9461614311 1046408070

CHENUXO Fuel Injection Pump Engine Replacement Parts , Compatible With Mitsubishi Pajero L200 2.5 TD ZEXEL 9461614311 1046408070 || Filtering impurities: It can effectively filter impurities in fuel and maintain engine and fuel system components. || Quick response: It has the ability to start and respond quickly, and can quickly establish stable fuel pressure. || Efficient and energy-saving: It can meet the fuel demand of the engine while reducing energy consumption, which helps to improve fuel economy. || High reliability: Adopting advanced manufacturing processes to effectively reduce wear and tear. Ensure stable operation in various harsh environments.

CHENUXO Fuel Injection Pump Engine Replacement Parts , Compatible With Mitsubishi Pajero L200 2.5 TD ZEXEL 9461614311 1046408070 || Filtering impurities: It can effectively filter impurities in fuel and maintain engine and fuel system components. || Quick response: It has the ability to start and respond quickly, and can quickly establish stable fuel pressure. || Efficient and energy-saving: It can meet the fuel demand of the engine while reducing energy consumption, which helps to improve fuel economy. || High reliability: Adopting advanced manufacturing processes to effectively reduce wear and tear. Ensure stable operation in various harsh environments.

Include in #2:

104740-8070

as FUEL INJECTION PUMP

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Drain the cooling system. 2. Loosen hose clamps (1) and (3). Disconnect hoses (2) and (4). 3. Support pump (5) and remove four bolts (6). 4. Remove elbow (7) and the gasket. The following steps are to install the water pump.5. Install a new gasket and elbow (7).6. Put the water pump (5) and elbow (7) in position and install four bolts (6).7. Put hoses (2) and (4) in position on elbow (7) and tighten the clamps (1) and (3).8. Fill the cooling system to the correct level. See the Maintenance Manual.

Perform Scheduled Oil Sampling after performing service work to check for coolant leakage and contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.

Disassemble And Assemble Water Pump

Start By:a. remove water pump

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove bolt (15) and the washer. Remove bearing (12) and gear (10) as a unit.2. Use tooling (A), (C) and a press, and remove bearing (12) from gear (10).3. Remove snap ring (8) with tool (B).4. Remove two bolts (1), the washers, cover (14) and gasket (2) from water pump housing (18).5. Loosen bolt (13) approximately 6.4 mm (.25 in). Hit the bolt with a soft hammer to loosen impeller (16).6. Remove bolt (13), washer (11), impeller (16), spring (3) and seal assembly (4).7. Remove bearing (7) and shaft (9) as a unit.8. Use tooling (A), (C) and a press to remove bearing (7).9. Remove ceramic seal (5) and seal (17).10. Use tool (C) to remove lip-type seal (6). The following steps are for assembly of the water pump.11. Install lip-type seal (6) in water pump housing (18) with tool (C). The lip of the seal must be toward the bearings. Put clean engine oil on the lip of the seal.12. Install shaft (9) in bearing (7) with a press.13. Install shaft (9) and bearing (7) as a unit in water pump housing (18).14. Install snap ring (8) with tool (B).

Clean water only is permitted for use as a lubricant for assembly. Do not damage or put hands on the wear surface of the carbon ring or the ceramic ring. Install the ceramic ring with the smoothest face of the ring toward the carbon seal assembly.

15. Put ceramic ring (5) in position in seal (17). Use hand pressure and tool (D) to install the ceramic ring.16. Remove spring (3) from seal assembly (4). Use hand pressure and tool (D) to install the seal assembly. Push seal assembly (4) on shaft (9) until it makes light contact with ceramic ring (5).17. Install spring (3) on seal assembly (4). Put impeller (16) in position on shaft (9), and install washer (11) and bolt (13). Tighten bolt (13) to a torque of 38.0 1.5 N m (28 1 lb