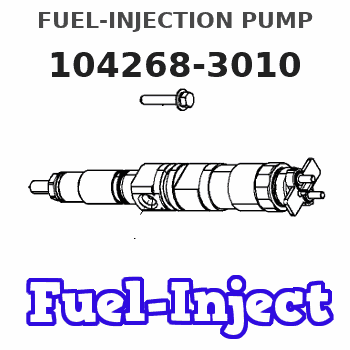

Information fuel-injection pump

BOSCH

9 410 617 249

9410617249

ZEXEL

104268-3010

1042683010

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104268-3010 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1. | [1] | 141055-7300 | PUMP HOUSING |

| 5. | [1] | 141187-2020 | PLUNGER-AND-BARREL ASSY |

| 7. | [2] | 141133-9300 | CAPSULE |

| 7. | [2] | 141133-9300 | CAPSULE |

| 8. | [2] | 141482-9500 | O-RING |

| 8. | [2] | 141482-9500 | O-RING |

| 12. | [1] | 141145-4920 | DELIVERY-VALVE ASSEMBLY |

| 19. | [2] | 016421-0700 | BACKUP RING |

| 20. | [1] | 141118-3002 | O-RING |

| 22. | [6] | 141124-4200 | BLEEDER SCREW |

| 24. | [2] | 016421-0600 | BACKUP RING |

| 25. | [3] | 141485-1002 | O-RING |

| 50. | [1] | 141215-7401 | COMPRESSION SPRING |

| 51. | [1] | 141216-5100 | SLOTTED WASHER |

| 52. | [1] | 141217-8300 | SLOTTED WASHER |

| 53. | [1] | 141218-9000 | GUIDE |

| 55. | [1] | 141220-2900 | LOCKING WASHER |

| 60. | [1] | 141291-1500 | CONTROL RACK |

| 77. | [1] | 141292-3800 | CONTROL SLEEVE |

| 81. | [1] | 141245-2000 | POINTER |

| 82/1. | [0] | 023500-6210 | PLAIN WASHER D11&6.4T1.5 |

| 82/1. | [0] | 029300-6010 | PLAIN WASHER D11&6.4T0.8 |

| 82/1. | [0] | 029300-6020 | PLAIN WASHER D11&6.4T0.35 |

| 83. | [1] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 90. | [1] | 029112-2020 | CAPSULE |

| 91. | [1] | 026522-2740 | GASKET D26.9&22.2T1 |

| 160. | [1] | 141418-2600 | SET OF NUTS |

| 161. | [1] | 141403-2000 | GASKET |

| 163. | [2] | 373658-1400 | CAPSULE |

| 163. | [2] | 373658-1400 | CAPSULE |

| 164. | [2] | 141403-1800 | GASKET |

| 164. | [2] | 141403-1800 | GASKET |

Include in #1:

101401-9121

as _

Include in #2:

104268-3010

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Wear goggles, gloves, protective clothing, and a National Institute for Occupationsl Safety and Health (Niosh) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Anyone working around or near the Cat Diesel Particulate Filter (DPF) system should be trained in the proper safety precautions and procedures including emergency shutdown, MSDS sheets detail for the necessary safety precautions and procedures required for the handling of materials. These precautions and procedures must be followed.

Service on the Cat DPF system is to be done only by trained and qualified individuals. The training includes all electrical and mechanical service.

If there is any concern about the safety of this system, clear the area immediately of all personnel. Contact the appropriate person for further instructions.