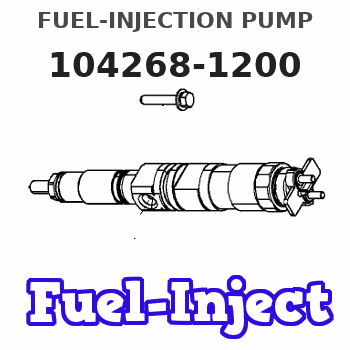

Information fuel-injection pump

BOSCH

9 410 618 001

9410618001

ZEXEL

104268-1200

1042681200

DAIHATSU

E326470190ZZ

e326470190zz

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104268-1200 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1. | [1] | 141055-0720 | PUMP HOUSING |

| 5. | [1] | 141187-2720 | PLUNGER-AND-BARREL ASSY |

| 7. | [1] | 141133-7001 | CAPSULE |

| 8. | [1] | 141485-1203 | O-RING |

| 12. | [1] | 141142-9520 | DELIVERY-VALVE ASSEMBLY |

| 19. | [2] | 016421-0700 | BACKUP RING |

| 20. | [1] | 141118-3002 | O-RING |

| 22. | [6] | 141124-4200 | BLEEDER SCREW |

| 24. | [2] | 016421-0600 | BACKUP RING |

| 25. | [3] | 141485-1002 | O-RING |

| 50. | [1] | 141215-7401 | COMPRESSION SPRING |

| 51. | [1] | 141216-5100 | SLOTTED WASHER |

| 52. | [1] | 141217-8300 | SLOTTED WASHER |

| 53. | [1] | 141218-9000 | GUIDE |

| 55. | [1] | 141220-2900 | LOCKING WASHER |

| 60. | [1] | 141291-1500 | CONTROL RACK |

| 68. | [1] | 141456-0700 | CYLINDER |

| 69. | [1] | 026524-2940 | GASKET D28.9&24.3T2 |

| 77. | [1] | 141292-2000 | CONTROL SLEEVE |

| 81. | [1] | 141245-2000 | POINTER |

| 82/1. | [0] | 023500-6210 | PLAIN WASHER D11&6.4T1.5 |

| 82/1. | [0] | 029300-6010 | PLAIN WASHER D11&6.4T0.8 |

| 82/1. | [0] | 029300-6020 | PLAIN WASHER D11&6.4T0.35 |

| 83. | [1] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 92. | [1] | 141401-2700 | BUSHING |

| 93. | [1] | 141402-6500 | EYE BOLT |

| 160. | [1] | 141418-2600 | SET OF NUTS |

| 161. | [1] | 141403-2000 | GASKET |

| 167. | [1] | 150948-0000 | INLET UNION |

| 168. | [1] | 150949-0100 | EYE BOLT |

| 169. | [2] | 150521-0800 | GASKET |

Include in #1:

101491-9725

as _

Include in #2:

104268-1200

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

104268-1200

E326470190ZZ DAIHATSU

FUEL-INJECTION PUMP

K 24FW FUEL INJECTION PUMP PF-1SV PF

K 24FW FUEL INJECTION PUMP PF-1SV PF

Information:

Use of Cat Diesel Fuel System Cleaner or Cat Diesel Fuel System Conditioner does not lessen the responsibility of the engine owner and/or responsibility of the fuel supplier to follow all industry standard maintenance practices for fuel storage and for fuel handling. Refer to the “General Fuel Information” article in this Special Publication for additional information. Additionally, use of Cat Diesel Fuel System Cleaner or Cat Diesel Fuel System Conditioner does NOT lessen the responsibility of the owner of the engine to use appropriate diesel fuel. Refer to the “Fuel Specifications” section in this Special Publication (Maintenance Section) for guidance.

Caterpillar strongly recommends that Cat Diesel Fuel System Cleaner be used with biodiesel and biodiesel blends. Cat Diesel Fuel System Cleaner is suitable for use with biodiesel/biodiesel blends that meet Cat biodiesel recommendations and requirements. Note that not all fuel cleaners are suitable for use with biodiesel/biodiesel blends. Read and follow all applicable label usage instructions. Also, refer to this Special Publication, "Distillate Diesel Fuel", article and also refer to the “Biodiesel” article, which includes Cat biodiesel recommendations and requirements.When used as directed, Cat Diesel Fuel System Cleaner has proven to be compatible with non-road Tier 4 U.S. EPA certified engines that are equipped with aftertreatment devices.Note: When used as directed, Cat Diesel Fuel System Cleaner will not raise fuel sulfur levels measurably in the final fuel/additive blend. Follow all applicable national, regional, and local laws, mandates, and regulations concerning the use of diesel fuel conditioners/additives.

When used as directed Cat Diesel Fuel System Cleaner will not raise fuel sulfur levels measurably in the final fuel/additive blend. But, in the U.S., aftermarket fuel additives (retail consumer level versus bulk fuel additives used at the fuel supplier/distributor level) with more than 15 ppm sulfur are NOT allowed to be used in applications where ULSD usage is mandated (15 ppm or less fuel sulfur). Note that Cat Diesel Fuel System Cleaner contains less than 15 ppm of sulfur and is acceptable for use with ULSD fuel.

Renewable and Alternative Fuels

Renewable fuels are derived from renewable resources such as planted crops and crop residues (referred to as biomass), waste, algae, cellulosic material, yard and food waste, etc. Renewable fuels reduce the carbon footprint of the fuels compared to fossil fuels on a Life Cycle Analysis basis. Caterpillar, through sustainability initiatives, supports the development and use of renewable fuels.Renewable fuels (other than biodiesel) and alternative fuels (such as but not limited to Gas-to-Liquid fuel) are typically >99% hydrocarbons (composed of carbon and hydrogen). An exception is biodiesel, which is an oxygenated renewable fuel. Biodiesel is discussed in a separate article in this Fuel section. Significant research is on going to develop renewable fuels and produce the fuels economically.Caterpillar is not in a position to test all varieties of renewable and alternative fuels that are advertised in the market place. If a renewable or alternative fuel fulfills the performance requirements described in Cat Fuel Specification, the latest version of "ASTM D975", the latest version of "EN