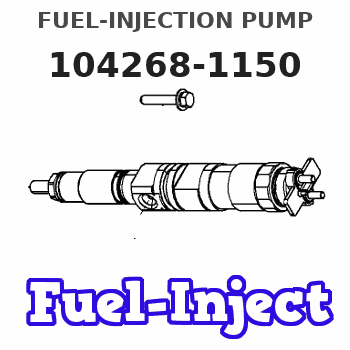

Information fuel-injection pump

BOSCH

9 410 617 646

9410617646

ZEXEL

104268-1150

1042681150

DAIHATSU

E326470060ZZ

e326470060zz

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104268-1150 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 27.5{280} |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE | 105012-4370 |

Scheme ###:

| 1. | [1] | 141055-0800 | PUMP HOUSING |

| 5. | [1] | 141187-1620 | PLUNGER-AND-BARREL ASSY |

| 7. | [2] | 141133-7000 | CAPSULE |

| 7. | [2] | 141133-7000 | CAPSULE |

| 8. | [2] | 141485-1201 | O-RING |

| 8. | [2] | 141485-1201 | O-RING |

| 12. | [1] | 141142-9520 | DELIVERY-VALVE ASSEMBLY |

| 19. | [2] | 016421-0700 | BACKUP RING |

| 20. | [1] | 141118-3000 | O-RING |

| 22. | [6] | 141124-4200 | BLEEDER SCREW |

| 24. | [2] | 016421-0600 | BACKUP RING |

| 25. | [3] | 141485-1000 | O-RING |

| 50. | [1] | 141215-7401 | COMPRESSION SPRING |

| 51. | [1] | 141216-5100 | SLOTTED WASHER |

| 52. | [1] | 141217-8300 | SLOTTED WASHER |

| 53. | [1] | 141218-9000 | GUIDE |

| 55. | [1] | 141220-2900 | LOCKING WASHER |

| 60. | [1] | 141291-1500 | CONTROL RACK |

| 77. | [1] | 141292-0400 | CONTROL SLEEVE |

| 81. | [1] | 141245-2000 | POINTER |

| 82/1. | [0] | 023500-6210 | PLAIN WASHER D11&6.4T1.5 |

| 82/1. | [0] | 029300-6010 | PLAIN WASHER D11&6.4T0.8 |

| 82/1. | [0] | 029300-6020 | PLAIN WASHER D11&6.4T0.35 |

| 83. | [1] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 160. | [1] | 141418-2600 | SET OF NUTS |

| 161. | [1] | 141403-2000 | GASKET |

| 163. | [2] | 373658-1400 | CAPSULE |

| 163. | [2] | 373658-1400 | CAPSULE |

| 164. | [2] | 141403-1800 | GASKET |

| 164. | [2] | 141403-1800 | GASKET |

Include in #2:

104268-1150

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Illustration 11 g03159376

Install the new emissions certification film (6), information label (7), and serial number plate on the cylinder block according to the installation instructions received with the labels and plate.Note: Destroy the old emissions certification film and serial number plate.Operation and Maintenance

There are several specific messages on this machine. The exact location of the messages and the description of the messages are reviewed in this section. Become familiarized with all messages.Make sure that all the messages are legible. Clean the messages or replace the messages if you cannot read the words. Replace the illustrations if the illustrations are not legible. When you clean the messages, use a cloth, water, and soap. Do not use solvent, gasoline, or other harsh chemicals to clean the messages. Solvents, gasoline, or harsh chemicals could loosen the adhesive that secures the messages. Loose adhesive will allow the messages to fall.Replace any message that is damaged, or missing. If a message is attached to a part that is replaced, install a message on the replacement part. Any Cat® dealer can provide new messages.

Illustration 12 g06238625

Location of oil and fuel films

(1) Oil film

(2) Fuel filmEngine Oil (1)

This film is located in front of the engine oil filler tube and next to the fuel tank breather, on the right side of the machine.

Illustration 13 g02448560Cat® DEO-ULS oils and oils that satisfy the "API CJ-4"and/or "ACEA E9" requirements are required for engines that are equipped with a diesel particulate filter.Diesel Fuel Requirements (2)

This film is located film next to the fuel filler and fuel tank inspection cover on the right side of the machine.

Illustration 14 g03619316Use Ultralow Sulfur Diesel (ULSD) fuel.The Environmental Protection Agency (EPA) defines Ultra-Low Sulfur Diesel (ULSD - S15) as a diesel fuel with a sulfur content not to exceed 15 parts per million (ppm(mg/kg)) or 0.0015 percent by weight. Engines are equipped with exhaust after-treatment systems are designed to run on ULSD only. Use of LSD or fuels higher than 15 ppm (mg/kg) sulfur in these engines will reduce engine efficiency and engine durability. Damage to the emissions control systems and/or shortened service interval will occur. Failures that result form the use of fuels are not Caterpillar factory defects. Therefore the cost of repairs would not be covered by a Caterpillar warranty.In Europe, ultra low sulfur diesel fuel will have a maximum of 0.0010 percent (10 ppm (mg/kg)) sulfur and is typically referred to as “sulfur-free”. This sulfur level is defined in European Standard "EN 590:2004".Operational Requirements

Ensure that the following operational requirements are applied when machines are fitted with a wall flow diesel particulate filter.Fuel

Sulfur levels must not exceed 15 ppm

Do not use fuel additives, biofuels, or alternative diesel fuels not authorized by CaterpillarOil

Use manufacturer recommended engine oilMachine Operation

Avoid excessive or unnecessary idling and low load operation. High load, high temperature is recommended for machines equipped with flow through diesel particulate filtersLubricant Viscosities - Fluid Recommendations

Engine Oil

Cat® oils have been developed and tested to provide the full performance and life that has been designed and built